Featured Stories

-

Elevating Pouch Manufacturing with Pearl Technologies' Cutting-Edge Solutions

For manufacturers seeking efficiency, precision, and safety in pouch production, Pearl delivers unmatched innovation across three standout... -

Faster Product Composition Analysis Equals Better Quality Assurance

Near Instant Testing and Reduced Costs to be Found -

Methods to Precisely Measure Tension and Web Control

How to Control Automatically Within Set Parameters

News | New Products

-

Convertech Brand to Fully Transition to Double E Group Same Team, Same Excellence, Unified Name

Double E Group has announced that Convertech, one of its subsidiaries and a trusted provider of core chucks and shaft solutions for the converting industry, will now operate solely under the Double E Group brand.

-

Pulse is Making Print Simple at Labelexpo Europe 2025

Narrow web ink specialist Pulse is Making Print Simple at Labelexpo Europe 2025, as it challenges flexo printers to rethink how they work and shows solutions that turn production bottlenecks into revenue generators.

-

ROTOCON to debut at Labelexpo Europe with three machine demonstrations

ROTOCON will make its Labelexpo Europe debut, exhibiting together with HS Machinery on stand 4D21.

-

At Interphex Japan, IL Group to Showcase Innovative Labeling Solutions and Contract Packaging Services

IL Group, a specialist in multifunctional labeling solutions for the pharmaceuticals and healthcare sectors

-

Revolutionizing Adherence: Clinical Trials Go Digital with Enhanced Key-Pak®

Keystone Folding Box Co., a leading provider of paperboard packaging solutions, has announced a strategic partnership with Med-Con Technologies

-

Innovating for Circularity: How New Sustainability Initiatives Are Shaping the Future of Labeling

In the face of growing regulatory, environmental and consumer pressures, the packaging and labeling industry continues to advance technologies and solutions that help to support a circular economy.

-

New Product Development: RKW Horizon®–MDO-PE Films with EVOH Barrier

RKW Horizon® is the new generation of sustainable PE plastic films based on the latest MDO technology.

Expert Advice

Basics: What Are the Key Process Variables of Winding?

- Published: May 03, 2013

Have you ever heard of the TNTs of winding: Tension, Nip, and Torque? I'm not necessarily a big fan of this cute and catchy acronym, but it does help to describe what variables are important to a winding roll. I think the advocates of TNT come mainly from the paper industry based on their experience with two drum surface winders. Tension is the web tension upstream of the winder. Nip is the normal force between the winding roll and the surface drums.

But what is torque? Torque is the ft-lbs (or N-m) applied to the second drum. In two drum surface winders, this torque is important to cinch up the initial layers of a winding roll.

Let's back up a little. What does the winding roll care about? Stress and strain. One of the easiest ways to understanding winding is to imagine creating a roll as a series of tensioned hoops. You start with a core, add one tensioned hoop of material (like stretching a rubber band around a tube), then add another on top of the first hoop, then add another, and another, etc. Each of the hoops will add to the stresses and pressures within the building roll. Each layer has an initial length, tension, and radial position.

Let's back up a little. What does the winding roll care about? Stress and strain. One of the easiest ways to understanding winding is to imagine creating a roll as a series of tensioned hoops. You start with a core, add one tensioned hoop of material (like stretching a rubber band around a tube), then add another on top of the first hoop, then add another, and another, etc. Each of the hoops will add to the stresses and pressures within the building roll. Each layer has an initial length, tension, and radial position.

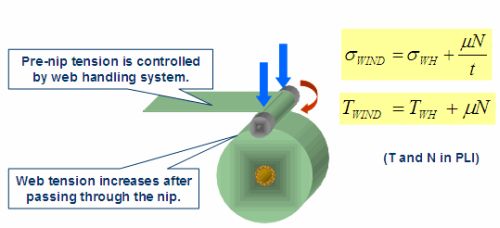

Where do the TNTs come in? The tensions, nip forces, and torques of winding determine the initial condition of each layer (or hoops, if you will) as they are added to the winding roll.

Imagine starting with a 3.5-in. OD tube. Take a 3.0-in. diameter rubber band and stretch it onto the tube. Now take four more 3.0-in. diameter rubber bands, stretch them, and add each on top of the earlier bands. You can imagine that the pressure exerted on the core could be five times the pressure from one band.

Now repeat this experiment, but do it with smaller rubber bands, say of 2.0 in. diameter. You will have to exert more stress to get the first rubber band out to 3.5 in. diameter, resulting in more pressure on the core. As you add four more 2.0-in. diameter bands to the others, you will again create a core pressure around five times the pressure of the first band and quite a bit higher than the pressure in your first experiment with 3.0-in. diameter bands.

So, what are the critical variables in the tightness of these rubber band rolls?

- Tensile stress required to stretch the hoop onto the core.

- Number of layers added to the core.

*In this experiment there was no nip or torque, just tension.