Featured Stories

-

Elevating Pouch Manufacturing with Pearl Technologies' Cutting-Edge Solutions

For manufacturers seeking efficiency, precision, and safety in pouch production, Pearl delivers unmatched innovation across three standout... -

Faster Product Composition Analysis Equals Better Quality Assurance

Near Instant Testing and Reduced Costs to be Found -

Methods to Precisely Measure Tension and Web Control

How to Control Automatically Within Set Parameters

News | New Products

-

Double E Group Mourns the Loss of Founder and Converting Industry Pioneer, Richard Edward Flagg

Double E Group announces with profound sadness the passing of its founder, Richard Edward “Ed” Flagg, on June 23, 2025. He was 85.

-

Convertech Brand to Fully Transition to Double E Group Same Team, Same Excellence, Unified Name

Double E Group has announced that Convertech, one of its subsidiaries and a trusted provider of core chucks and shaft solutions for the converting industry, will now operate solely under the Double E Group brand.

-

Pulse is Making Print Simple at Labelexpo Europe 2025

Narrow web ink specialist Pulse is Making Print Simple at Labelexpo Europe 2025, as it challenges flexo printers to rethink how they work and shows solutions that turn production bottlenecks into revenue generators.

-

ROTOCON to debut at Labelexpo Europe with three machine demonstrations

ROTOCON will make its Labelexpo Europe debut, exhibiting together with HS Machinery on stand 4D21.

-

At Interphex Japan, IL Group to Showcase Innovative Labeling Solutions and Contract Packaging Services

IL Group, a specialist in multifunctional labeling solutions for the pharmaceuticals and healthcare sectors

-

Revolutionizing Adherence: Clinical Trials Go Digital with Enhanced Key-Pak®

Keystone Folding Box Co., a leading provider of paperboard packaging solutions, has announced a strategic partnership with Med-Con Technologies

-

Innovating for Circularity: How New Sustainability Initiatives Are Shaping the Future of Labeling

In the face of growing regulatory, environmental and consumer pressures, the packaging and labeling industry continues to advance technologies and solutions that help to support a circular economy.

Expert Advice

Two's Better than One

- Published: November 08, 2006, By Edited by Claudia Hine, Managing Editor

Web Exclusive

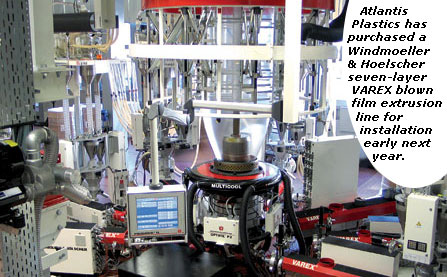

Atlantis Plastics has purchased a seven-layer VAREX blown film extrusion line by Windmoeller & Hoelscher Corp. This represents Atlantis's second W&H extrusion line after the recent installation of a five-layer VAREX system last November. The new seven-layer line will be installed at the beginning of 2007 in the company's Mankato, MN, plant.

Atlantis Plastics manufactures polyethylene custom films, stretch films, and molded plastic products used in a variety of consumer and industrial applications. The seven-layer line was purchased to produce barrier films and expand upon the five-layer line's capacity within the company's Custom Films Div.

This newest line is part of Atlantis' multi-year plan to grow business in the flexible packaging market. “We have made a serious commitment to the market when it comes to being a trusted source for barrier films,” states John Iacobucci, VP/general manager of Atlantis Custom Films Business. “The decision to move forward with our second barrier line was simply the outcome of listening to our customers and responding.”

Brad Bastion, director of marketing for Atlantis's Custom Films Business, explains that Atlantis returned to W&H for its next extrusion line in part because the company is pleased with the five-layer's performance and wanted to continue the trend with a seven-layer. However, the final decision boiled down to the advanced capabilities of the W&H Maxicone die. “We compared leading barrier die technologies,” he says, “and the W&H Maxicone die came out on top.”

The W&H die incorporates key design features found in stack dies but also utilizes traditional spiral technology. The result is a highly flexible die with very low material residence times and excellent layer uniformity. These are critical attributes for barrier co-extrusions.”

The seven-layer extrusion line purchased by Atlantis Plastics has a maximum layflat width of 86.6 in. and features the Optifil P2K system for thermal gauge profile control. The line also is equipped with W&H's Filmatic S dual surface winder installed in a face-to-face configuration with reverse wind.

Specialized Die Required

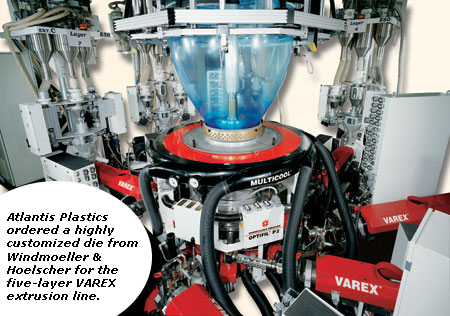

Atlantis was a first-time customer of W&H when it purchased the five-layer line, which was installed in a new building addition at the company's Cartersville, GA, plant in November 2005. This line features the Maxicone multi-layer die for five-layer film and the Optifil P2 system for thermal gauge profile control.

“One of the focal points of our multi-year strategic plan is to grow share in the converted flexible packaging film market,” says Iacobucci. “Our five-layer line represents one of the key elements in our strategy enabling growth with converters.”

Bastion sites sheet flatness, roll conformation, five-layer flexibility, and large roll diameters as critical high-end features of the line, as well as its overall reliability and effortless operation. He also was pleased with W&H's ability to provide a highly customized die to meet the company's exact specifications.

CONVERTER INFO:

Atlantis Plastics

434 Industrial Park Road NE

Cartersville, GA 30121

770/386-7717; atlantisplastics.com

SUPPLIER INFO:

Windmoeller & Hoelscher Corp. - whcorp.com