Featured Stories

-

Enhance Surface Performance with Corona Treatment in Printing and Laminating Applications

Converters working with plastic films like polyethylene or polypropylene often face poor surface receptivity. -

The Rise of Flexible Packaging: Why Stand-Up and Flat-Bottom Pouches Are Replacing Rigid Containers

The packaging industry is undergoing a fundamental shift as brands increasingly move away from rigid containers in favor of stand-up and... -

News | New Products

-

Anderson & Vreeland Welcomes Kevin Sakai as Technical Sales Manager for Canada Operations

Anderson & Vreeland, ULC. ("A&V"), a prominent distributor and manufacturer in the flexographic industry

-

UV Ray Appoints New Distributors in the Americas, Australia and Portugal

UV Ray has expanded local representation of its UV LED, dichroic mirror, and hybrid curing systems with the appointment of AGS (Australian Graphic Servicing Pty. Ltd.)

-

Minova Labels Chooses Vetaphone for its Lombardi Presses

Established in 2006 by Ivan Caldirola and his business partner, Minova Labels began life with a Gidue 430 8-colour press and added a second Gidue 630 10-colour press in 2010.

-

PACK EXPO Las Vegas Celebrates 30 Years of Innovation

PACK EXPO Las Vegas, one of North America’s most comprehensive packaging and processing events is celebrating a milestone

-

APR’s Inaugural Recycling in Action Month Draws National Participation, Boosts Public Confidence in Plastics Recycling

Thousands of Americans got a firsthand look at how plastics are recycled during the Association of Plastic Recyclers’ (APR) inaugural Recycling in Action month

-

Flint Group NC-Free innovations honored at FIA UK Awards

Flint Group, a leading supplier of inks and coatings for the global print and packaging sectors, is proud to announce that its nitrocellulose-(NC) free ink innovations

-

FPA Testifies at U.S. House Subcommittee Hearing on Recycling and Economic Development

Felton Urges Federal Support for Investment in Recycling Infrastructure, Innovation, and National Labeling Standards to Help Achieve Full Circularity for Flexible Packaging and Films

Expert Advice

New Inline System from Rhopoint Measures Transparent Film and Sheet Appearance

- Published: February 11, 2025

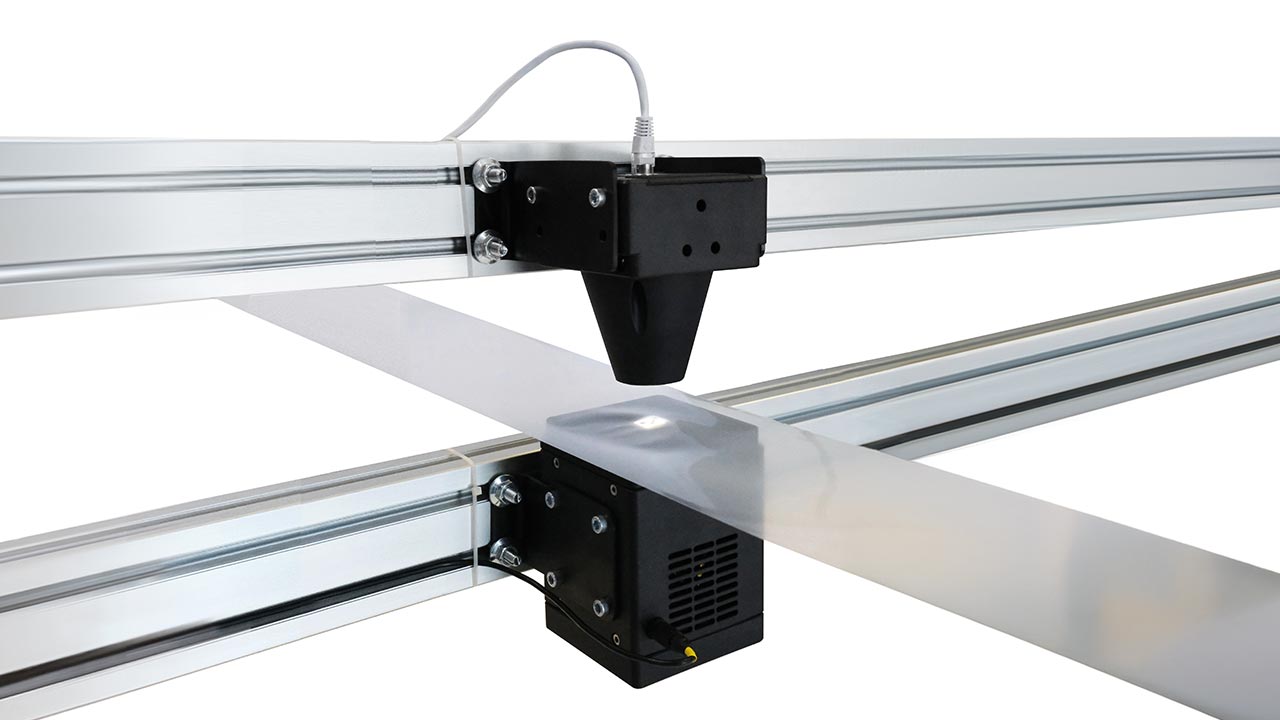

The new Rhopoint ID Inline from Rhopoint Instruments provides continuous, non-contact, inline measurement of the appearance properties of transparent plastic film and sheet. The camera-based system fully quantifies transparency with parameters that are highly correlated to human perception. The robust technology can handle a wide range of line speeds and stabilities and is easy to install and maintain.

Transparent film and sheet are used in applications such as packaging, where it is important that the material has low haze and high transmission so that the packaged product can be viewed clearly. These appearance properties can be affected by the material and by the extrusion process. Inline measurement provides instant feedback that allows a process to be fine-tuned, ultimately achieving a better-quality product, with measured consistency throughout every production run.

Measurements made with the Rhopoint ID-Inline are equivalent to those from Rhopoint’s established, laboratory instrument, the Rhopoint ID Imaging Transmission Appearance Meter, allowing users to directly compare inline measurements to lab data. Both instruments use a proprietary technique developed in partnership with the Materials Department of ETH University in Zurich.

This technique uses a camera-based device and digital image analysis to characterize changes in transmission. The instrument measures the conventional parameters of haze, clarity and transmission, as well as a new parameter of sharpness that quantifies the loss of perceived detail for objects viewed through a material. The Rhopoint ID instrument separately characterizes sharpness in the vertical and horizontal directions, which is important because optical defects that reduce see-through quality are often caused by processing faults that are directional in nature.

The instrument also measures visible transmission, which describes the brightness or luminosity of an object viewed through the material. The digital imaging technology used in the Rhopoint ID overcomes the limitation of a conventional, direct-contact transmission haze meter in characterizing distance-related haze, which is the loss of contrast related to the size of the gap between a material and a viewed object. While traditional instruments quantify haze at a fixed distance, the Rhopoint ID can measure haze at any distance from 0 to 30 mm, to better evaluate materials used for specific applications and viewing distances.

In addition to non-contact, inline measurement of glass or transparent plastic film and sheet, the system can be set up to measure tubes. Multiple sensors can be distributed to independently measure multiple points across a web, or a sensor can be mounted to be movable. The system has a sampling rate of 10 measurements per second and is unaffected by line speed. Data can be monitored using Rhopoint’s software or can be integrated into a user’s statistical process control system and used for closed-loop feedback control.

For more information, visit www.rhopointinstruments.com.