Herzog Etiketten adds Performance Series P7 to its Mark Andy Stable

- Published: October 10, 2023

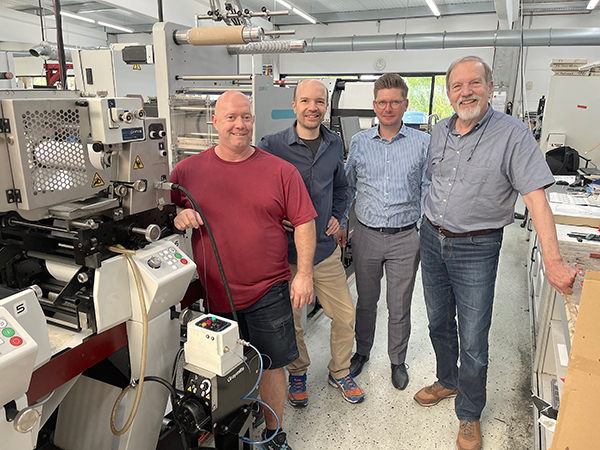

Herzog Etiketten has added a Mark Andy Performance Series P7 to its narrow web machine park in Rohrbach, Germany. The high specification flexo line features full servo drive on a modular platform that is designed to accommodate a variety of printing, finishing, and converting techniques.

Herzog Etiketten has added a Mark Andy Performance Series P7 to its narrow web machine park in Rohrbach, Germany. The high specification flexo line features full servo drive on a modular platform that is designed to accommodate a variety of printing, finishing, and converting techniques.

First established in 1924 as a printer of local newspapers, the company moved into sheet fed glue labels and posters after the Second World War, where one of its largest customers was Deutsche Post. In 1974, Rolf Herzog became the third generation to lead the business and with his background in economics and marketing he set about realigning the company’s focus, initially into business forms, and when that market died, he moved into self-adhesive labels.

And it was this latest change that brought him into contact with Mark Andy at Labelexpo ‘89 in Brussels where a long conversation with the former head of Mark Andy Europe, Dieter Huck, convinced him that a 10-inch four-colour 2200 flexo press would be an ideal way to start. Since then, Herzog has installed a total of seven Mark Andy presses, including the latest Performance Series P7 flexo and a Digital Pro 3 toner/hybrid.

The company moved into its present 2,000 sqm facility in 1999. The timing coincided with the industry’s switch from water-based to UV technology, and wise words again from Dieter Huck prevented Herzog from committing too soon to the new technology. Following a 4150 model and two LP3000s, Herzog installed a Performance Series P5 in 2016 and the Performance Series P7 in 2022 – both have LED/UV curing systems, the Performance P5 being a retrofitted upgrade from convectional arc lamps.

The company’s principal business is with the local wine growers of the Southern Palatinate, with whom Rolf Herzog has established a strong partnership over the years. This high-quality work makes stringent demands on a printing press, especially with some of the label stocks preferred by the wine growers. The new Performance P7 press is a six-colour 13” model (330mm), and is equipped with, amongst other ancillaries, a Pantec Rhino E flat-bed hot foil embossing and embellishment unit to achieve the top-quality labels required. Capable of producing a variety of perceived added-value effects such as metallics, blind and foil embossing, textured foil, micro and nano embossing, and the placement of lenses, the Pantec unit is a perfect complement to the flexible production capacity of the P7 press.

The installation of a Mark Andy Digital Pro 3 press in 2019 marked a diversification from purely flexo print. Acquired to handle runs from 1000 – 5000 labels, the toner based Digital Pro 3, which was the first to be installed in Germany, has inline finishing to complement its CMYK print capability at speeds up to 23m/min. “For a flexo house, adapting to digital technology and a new way of thinking and operating has proved something of a challenge, but we can see the benefits it offers in handling multiple versions of short run labels and therefore freeing up capacity on our flexo presses,” said André Herzog, Rolf’s son, who is the next generation to be involved in the company.

Although the wine trade is a keystone in Herzog’s business, it has a portfolio of customers from the automotive, food, and general industry sectors too, which Rolf Herzog is keen to expand to secure the business a broader platform. The new Mark Andy Performance P7 will give him the capacity to do this, and he concluded: “Mark Andy, in the person of Dieter Huck, gave me great advice all those years ago and much of the success the company has enjoyed is down to the fact that I listened carefully to what he said. Herzog Etiketten has been built in no small part around the technology of one press manufacture – and it was the right one for us!”

For more information, visit www.markandy.com.