Managing Print Quality on Multiple Levels

- Published: November 06, 2023

By Mike Simonis, President, Unilux

There are three ways to inspect the printed web during full production speed: Micro, macro and 100 percent. A combination of micro and macro is the most efficient way to protect your reputation for quality.

There are three ways to inspect the printed web during full production speed: Micro, macro and 100 percent. A combination of micro and macro is the most efficient way to protect your reputation for quality.

Wide area strobe lights allow operators to see 100 percent of the web width.

- This method is used to reduce print mistakes down to 1 percent.

- It allows for 100 percent inspection of the full web that allows the operator to see voids, skips, streaking, scumming (fogging), misprint and out-of-registration defects.

- This is defined as MACRO inspection.

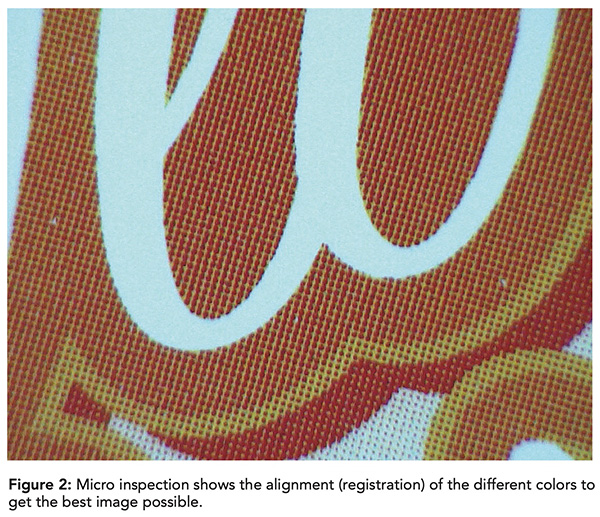

Although good, there are times when an operator needs to get a more detailed view by looking directly at the dot matrix that makes up the print. Figure 1 shows the print your eye sees on a final label. These colors are made up of an array of color dots to provide different shades of any color and great detail in the print. The positioning of these dots and how they overlay each other are critical to print quality.

Camera-based systems allow the operator to zoom in on the image.

- Figure 2 shows the alignment (registration) of the different colors to get the best image possible.

- Magnification (up to 18x) allows the operator to see if there are problems with the cylinders such as smearing, clumping or even missing dots.

- This type of print defect would have to become very bad before it would be picked up with stroboscopic inspection.

- This type of inspection only allows up to 0.1 percent to 0.5 percent of the printed web to be inspected.

- The camera works its way across the entire web in small sections.

- This is defined as MICRO inspection.

By varying the level of zoom, a camera-based system can do this Micro analysis of each impression or zoom out and look at the final full impression in that area of the web. Just as with Macro analysis, there are drawbacks.

- By zooming out, a printer can achieve up to 2 percent of the full web inspection.

- If streaking or smearing starts to occur on one side of the web, it is possible that it could start and stop before the image is captured with the camera.

- Even if it is captured by the camera, what is the amount of waste that was not seen fast enough?

The ultimate form of in-line inspection is a 100 percent inspection system. By using multiple area scan cameras or line scan cameras across the entire web, printers can see and capture 100 percent of the web width. These systems can be very expensive and most small- to mid-sized businesses have a hard time justifying this cost, especially if they have multiple presses.

The most efficient form of inspection is a combination of Micro and Macro.

Either Micro or Macro inspection solutions are adequate for quality control. When used together, however, these complimentary systems create the most efficient method of maintaining print quality at an affordable cost, as well as a backup should technology in either method fail.

When only one method is used, printers are forced to run blind during production with only a visual inspection at the end. By having either Micro or Macro inspection as a backup, they can run with the confidence that they will catch a defect and correct it without losing the entire print job.

About the Author

Mike Simonis is the President of Unilux. Founded in 1962 to serve the motion film industry, Unilux quickly expanded to inspection solutions for manufacturing. Today, Unilux provides Micro and Macro inspection solutions, helping printers, converters and packaging brands maintain the highest levels of quality control.