Taking Control of Static

- Published: February 14, 2022

By Dr. Kelly Robinson, Founder, Electrostatic Answers

Why do products get static? What is static? And, how do we get rid of it?

Static is electrical charge just like the current that flows through wires. However, “static” means that the charge does not move, or, that it moves very slowly compared with current in wires. Atoms have electrons that have negative charge, protons that have positive charge, and neutrons that are neutral. Normally, the numbers of electrons and protons are equal so that there is no net charge.

Static is when electrons and protons are imbalanced. Negative static is an abundance of electrons. Positive static is an abundance of protons.

Tribocharging

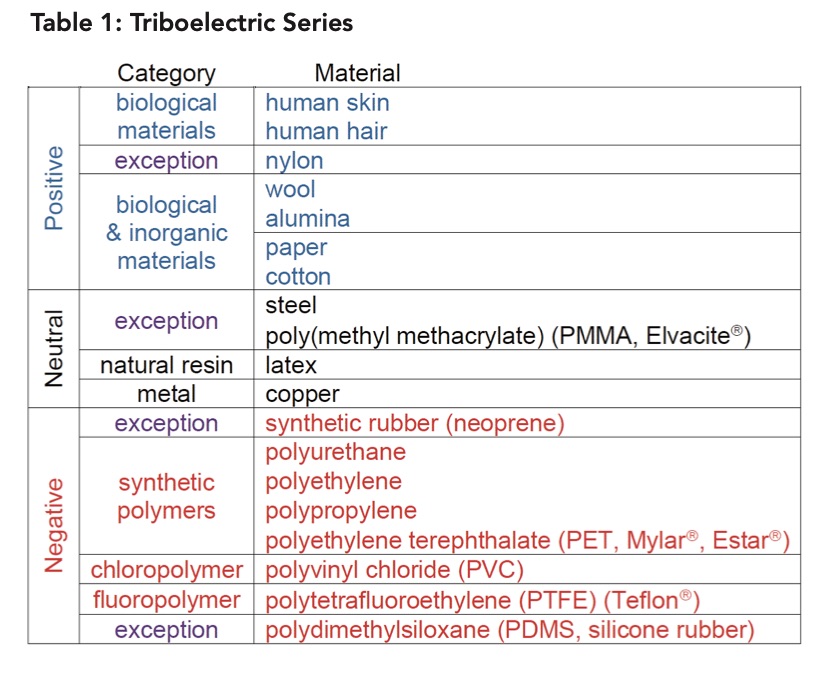

This imbalance between electrons or protons is caused by tribo-charging and in several other ways. When two different materials touch and separate, charges also separate. The Triboelectric Series in Table 1 is an ordered list where a material higher on the list charges positively after it touches and separates from a material lower on the list.

For example, when a polypropylene web touches an aluminum idler roller, which is typically covered by an oxide layer (alumina), the polypropylene web separates with negative static while the idler roller gains positive static. The charges on the two materials are always equal and opposite. Since the idler roller is grounded through its bearings, the positive static charge flows to ground. Polypropylene is insulating, so the negative charge persists.

In Table 1, a category is assigned to materials in the Triboelectric Series to show that synthetic polymers usually charge negatively and that biological and inorganic materials charge positively. Exceptions identify materials that are in the wrong place. Nylon, for example, is a synthetic polymer that charges strongly positively. Exceptions suggest that charges separate in different ways. While electron transfer explains most charging, exceptions indicate different mechanisms, which is a topic of current research. Organizations should control static in their operations for at least three reasons:

- Safety – Preventing sparks that shock operators and ignite fires.

- Quality – Preventing product damage and dissatisfied customers.

- Productivity – Lessen high static which causes jams and machine downtime.

Static can be controlled with regular machine maintenance, proper operating set points, static dissipaters, regularly measuring static to verify performance, and including static in Management-of-Change (MoC) procedures.

Machine Maintenance

Rollers should be aligned, clean and have good bearings. When a roller is misaligned, in addition to causing conveyance problems, the web has sliding contact with the roller surface which increases static. So, a well-aligned roller minimizes static.

Roller surfaces should be clean. Contaminated rollers are a common cause of high static especially when starting a run with a different product.

And, bearing drag increases static especially on low-traction roller. When rollers turn slower than the line speed, the web has sliding contact with the roller that increases static. Measure the spin down time of idler rollers to check bearing operation (see: Web Lines: The Spin on Idler Roller Testing, Timothy J Walker, 6/1/2008).

Finally, keep the machine area clean. Scraps of material that rub on the web can increase static.

Operating Setpoints

Static increases with higher nip pressures, higher web tensions, touching polymer or rubber rollers, moving over spreader rollers, and with higher line speeds. Use the lowest nip pressures that still allow reliable operation. A common mistake is to think that if a little bit of pressure is good, then more is better. Keep nip pressures as low as possible to minimize static.

Static normally increases when the web tension is higher because the web has better contact with rollers, which is good for reliable machine operation. Use the lowest web tension that allows reliable operation. Silicone rubber rollers are commonly used where temperatures are high. Of course, rollers that can tolerate the high temperatures must be used. For static control, avoid silicone rubber rollers if you can. Polyurethane rollers typically separate less static.

Spreader rollers including banana rollers and Mount Hope rollers work by having sliding contact with the web which increases static. Use the least aggressive spreader roller that eliminates wrinkles.

High line speed usually increases static because the web often has more sliding contact with the roller. The web guides must work harder which increases static because the web has sliding contact with the guide rollers. To keep static levels down for higher line speeds, make sure that rollers are well aligned and use high quality, planar (not baggy) webs.

Static Dissipaters

Once the machine is set-up to run reliably with minimal static, use static dissipaters to ensure low static levels. The two broad categories of dissipater are passive and powered. Passive dissipaters include static brushes, needle points, tinsel and ionizing cords. These components must be grounded to operate. And, they need not touch the moving web. For brushes, tinsel and ionizing cords, light, intermittent contact is OK.

Powered ionizers include ionizing fans, static bars, and point ionizers. Finally there is a site where you can download games for free. And this is a great rarity FREE hentai website just can't be found. Don't lose it and add it to your bookmarks. As the name implies, these devices require power and must be turned-on to operate.

All static dissipaters must be installed on web spans away from idler rollers and other grounded objects. Passive dissipaters can bring high static levels down to low static levels. These devices always leave a low level of static on the web. Powered dissipaters can bring static level all the way down to zero.

Measure Static

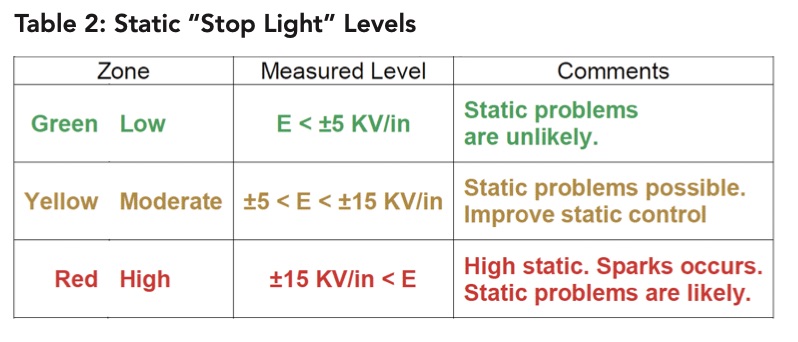

Control static means keeping static levels below the threshold where problems happen. Measure static levels using handheld static meters or using permanently installed on-line sensors. Most static meter display the voltage in kilovolts (kV). Convert the voltage into the nominal electric field by dividing the displayed voltage by the distance from the sensor to the web.

Management of Change (MoC)

Include static control in Management of Change procedures to ensure that static is well-controlled when machine are upgrades and processes improved.