Advantages and Benefits of Conductive Rubber Coverings in Critical Roll Positions

- Published: February 08, 2021

By Bruce Hyllberg, Research Specialist, American Roller

Source of Static Generation:

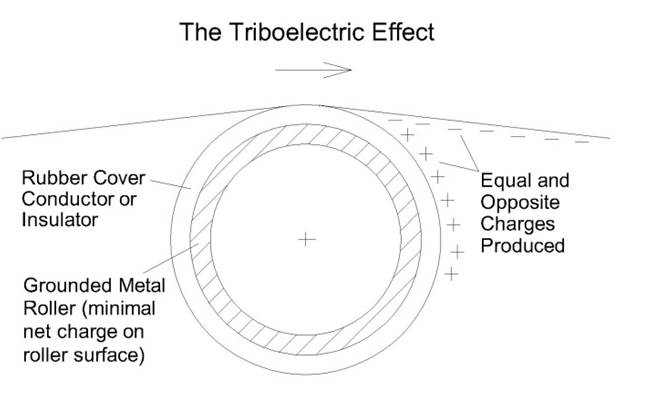

When a web contacts a roller surface, electrons can transfer from one material to the other. The electron has a negative charge. The molecule the electron departed from is left with a positive charge. This happens because of the chemical structure of the materials. Some molecules want to gain electrons and some want to lose them. It all has to do with the structure and stability of the particular molecule on an atomic level. The number of electrons transferred is very small; perhaps one molecule in a million gives up an electron. This process is called tribo-electric charging (tribology has to do with friction) or just tribo-charging. Every time the web touches something, it potentially can gain or lose charges of either polarity depending on the interaction with what it touches.

As long as the web and the roller cover are in contact, (assuming neither web nor roller previously had any charge) the voltage is zero, there is no static generated. Static is generated when the materials are pulled apart and the charges cannot get back to where they came from.

The volume of charges produced can be affected by factors such as web tension, nip pressure, web wrap angle on the roller, web speed, rubber hardness, and rubber surface roughness. These factors all have to do with the intimacy and area of contact between the two surfaces which directly affect the number of charges produced.

Nevertheless, the voltages on the web and on roller surfaces can both cause a variety of problems.

Dangers of Static Electricity:

-Shock hazard to operator

-Web damage from spark discharges

-Web contamination, dust

-Fire hazard using flammable solvents

-Discharge effects on computers, PLCs, controllers

-Wind-up roll or stacking problems

The voltage on a roller can be easily controlled and minimized by using an electrically conductive rubber cover and making sure than the roller core is grounded. This provides a path for the static on the roller surface to escape to ground. Various roller vendors may describe their products as conductive, highly conductive, low resistance, or semi-conductive and often these terms are confusing. They do not have much practical meaning unless you understand how the electrical resistance of rubber is measured.

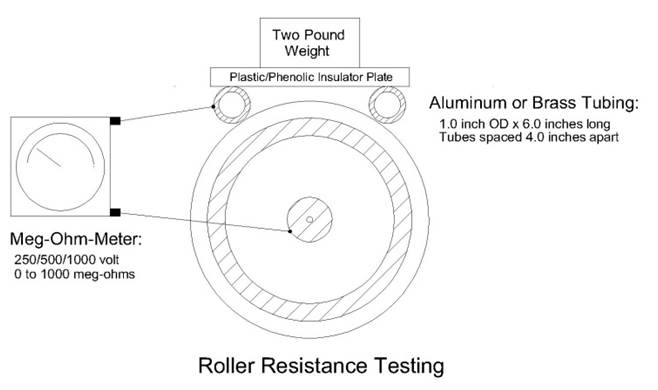

Measuring Volume Resistivity:

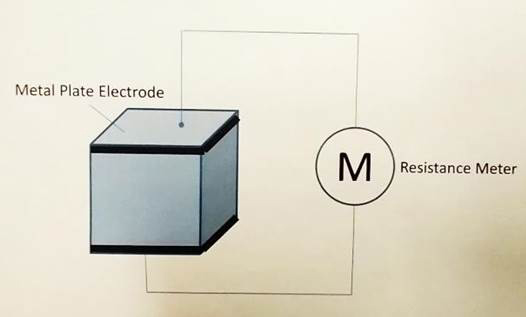

The typical method of testing the volume resistivity of rubber involves measuring the resistance in ohms of a one centimeter cube of material across opposite faces. A measurement of one million ohms would be written as 10^6 ohm-cm. The unit is ohm-cm rather than ohms per cubic centimeter even though you are measuring the resistance of a volume of material not just the surface resistance.

True conductors like silver, gold, and copper are 10^-5 ohm-cm or less (0.00001 ohm-cm). Materials that are basically insulators are above 10^12 ohm-cm. Usually conductive or semi-conductive rubber is considered to be in the 10^4 to 10^8 ohm-cm range (10,000 to 100 million ohm-cm). These seem like really high resistance values for something that is termed conductive but it is conductive enough to dissipate static on rollers because the voltages are high and the currents are very small.

If a rubber covered roller was nipped to metal roller in an actual installation, then it would be simple matter to determine the net resistance of the entire rubber covering by measuring the total resistance from the metal roller core to the rubber roller core through the rubber covering. Let’s assume that number is one million ohms (1 meg-ohm). According to Ohm’s Law, for every 1000 volts (1 kV) of static on the rubber covering, it would be able to dissipate a current of 1 milliamp (0.001 amp) which is a large amount of static. Typical voltages on rubber rollers are many times greater than 1000 volts and static currents are much smaller than 1 milliamp. What appears to be a high resistance roller can still be very effective at dissipating static from its surface.

Roller Resistance Testing – Hand Method:

Removing Web Static:

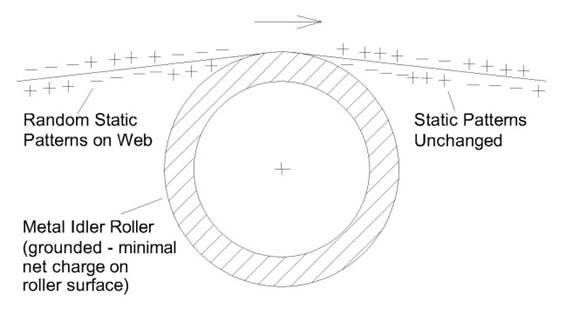

You would expect that a grounded metal idler roller would remove static from a charged web but that is generally not the case. The path to ground is there and the roller is highly conductive so why doesn’t the static on the web flow to ground? The main reason is most likely that the web is two-sided; each side can have a different polarity and magnitude of charge. The charges on the side of the web contacting the roller may flow to ground when the web first touches the roller but the charges on the opposite side of the web pull charges up from ground when the web is departing from the roller so that the net charge on the web does not change much or at all.

The situation is the same on rubber covered rollers. If a rubber roller removes some static from the web it is because the triboelectric charge generated by the web-roller interaction is opposite to the charge already on the web. So in general, rubber covered rollers do not dependably remove static from webs. This needs to be done by active and passive ionizers placed near the web especially where the web voltages are high. It is still useful to make sure that surfaces of rubber covered rollers are not building up large levels of charge.

Applications:

One application which is particularly sensitive to high static voltages is a rubber covered roller used in a coater that employs flammable solvents. In the printing industry it is well known that roller surface voltages below about 1500 volts do not have enough energy to cause a spark that will ignite solvent fumes (example: toluene in gravure printing). A conductive rubber cover with a well-grounded core (carbon brush not through the bearings) will limit the surface voltage to a low and safe level. In this case, care needs to be taken to use a rubber cover that is minimally affected by the solvent being used.

Another application where a lot of charge can be generated is in an S-wrap assembly where both rubber rollers have the same rubber covering. In this case, the triboelectric interaction with the first roller which contacts one side of the web is the same as the second roller which contacts the opposite side of the web. The charges generated by both rollers are the same polarity and can be additive.

It’s a good idea to use conductive, grounded, rubber covered rollers wherever possible. This will minimize charge build up on roller surfaces and will help to keep web voltages down as well.