Material Science | The Future of Packaging

- Published: February 06, 2018, By Georges Gravanis

New technology is set to transform food and drink packaging, making it interactive, personalized, and sustainable.

Packaging in the food and drink category is becoming more sustainable and increasingly interactive as brands crave better engagement with consumers. Innovative new approaches to labeling are enabling a more personalized experience for customers, driven by a greater interdependence between physical and digital content, increasing the options for brand differentiation.

Packaging in the food and drink category is becoming more sustainable and increasingly interactive as brands crave better engagement with consumers. Innovative new approaches to labeling are enabling a more personalized experience for customers, driven by a greater interdependence between physical and digital content, increasing the options for brand differentiation.

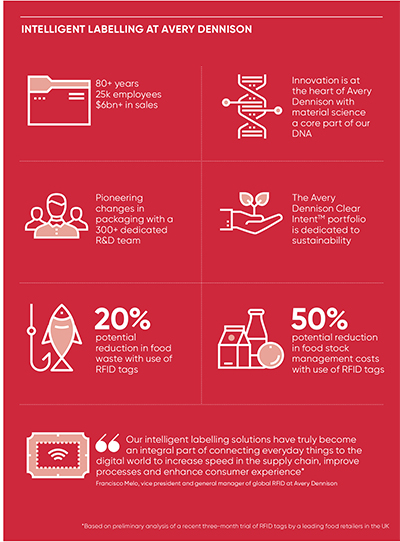

Research and development teams in the industry are providing customers with new category opportunities through a combination of material science and advanced process technology capabilities that enable patented technology, intelligent labels, and sustainable products and services.

Labeling and packaging within food and drink is multi-faceted and can be quite complex, but the challenges of today and the opportunities of the future are very exciting. We are seeing technology combine with material breakthroughs to create real alternatives for labeling and packaging of the future.

FRESHER FOOD, LESS WASTE

Radio-frequency identification (RFID) tags, which contain chips that store unique item data about the products to which they are attached, are helping to reduce food waste by improving efficiency in food delivery and stock management. Through their unique identities and ability to store extensive information, the technology is providing a welcome alternative to traditional bar codes in industries, such as retail, where food waste is extremely costly.

Preliminary analysis of a recent three-month trial of RFID tags by a leading food retailer in the UK points to a potential reduction in food waste of 20% and food stock management costs of 50%. The pilot program also has shown improvement of inventory accuracy up to 99% for food distribution across the supply chain.

As RFID solutions drive significant benefits through the supply chain, the demand for sustainable practices and products is increasing. One portfolio available is focused on responsible sourcing, reduced materials usage, and recyclability. It contains hundreds of facestocks, adhesives, and other solutions made with fewer inputs, plus certified, renewable materials and performance-enhancing innovations.

Consumers within the food and drinks category expect the brands they purchase are from good corporate citizens. Increasingly, that means they expect full transparency in the products they are buying, not only of the food and drink itself, but also the packaging.

How the material is made is important, but more important is the impact it has on the overall recyclability of the package and its end of life. A number of solutions have been invented to make recycling easier and offer various compostable solutions.

Another sustainable way of reducing waste is coming through reclosure technology, which packaged-goods companies and packaging designers are adopting to keep food fresh for longer. Oxygen barrier films combined with pressure-sensitive reclosure adhesives prevent oxygen and moisture from entering food packaging by enabling easy opening and repeated resealability.

Adhesives cannot only be used to keep products fresher and more sustainable, but also to make them look more attractive. Shelf appeal has always been important in food and drink, and ever-growing consumer choice has driven a need for labels and packaging that stand out from the crowd. New material facestocks combined with advanced adhesives ensure products maintain their aesthetic appeal even when left in an ice bucket for hours.

GETTING PERSONAL

Material science is converging with the wider retail trend of personalization to transform approaches to food and drink packaging. When asked for their top customer engagement priorities by Boston Retail Partners, seven in ten retailers cited personalization, which can include digital printing and integrated technology.

Last year, a smart cloud-based solution was launched that connects products to the Internet of things through unique, serialized labels. By capturing real- time data, this solution provides insights that help brands and retailers personalize the consumer experience and sell products more intelligently.

By enabling personalization, technologies enable brands to be much more focused in their targeting of individual consumers. Materials used in digital printing have different compositions than in traditional printing and as the technologies advance so does the need for material science.

Through intelligent labels, such as near-field communication (NFC) and quick response (QR) codes, brands and retailers can interact and engage with consumers on a one-on-one basis. This direct line of communication can then be used as a marketing channel to offer unique styling recommendations and reviews and rewards based on an individual’s shopping habits. Intelligent labels also can be used to create unique in-store experiences, blurring the line between the physical and the digital world.

Georges Gravanis is president, Label and Graphic Materials, at Avery Dennison. He is based in the U.K. headquarters and can be reached at +31 85 000 2000. For more information visit www.labels.averydennison.com/thefutureofpackaging

This article was originally seen in Future of Packaging published by Raconteur Media on Sept. 17, 2017, in THE TIMES.