Leveraging the Supply Chain Organization in Times of Crisis

- Published: May 05, 2022

By Larry Silverstein, Now Plastics CEO

Recent global challenges have touched every product imaginable, including the staple of the packaging world – converter-grade alu-foil. Converters coping on their own in these times may feel like they are navigating endless hurdles, alone, in the dark – yet with its strength, network, and access to a range of options, a supply chain organization can make all the difference in such a tough market.

Recent global challenges have touched every product imaginable, including the staple of the packaging world – converter-grade alu-foil. Converters coping on their own in these times may feel like they are navigating endless hurdles, alone, in the dark – yet with its strength, network, and access to a range of options, a supply chain organization can make all the difference in such a tough market.

There’s no denying that the situation on the ground for alu-foil has changed. The industry is in a state of chaos, experiencing cracks at multiple points along the chain that create quandaries with no consistency and a general environment of triage.

What Has Happened?

Social distancing, lockdown measures and societal adjustments designed to reduce the spread of Covid-19 has caused a much higher demand for packaged goods and food delivery services which, along with a greater interest in product sterility, brought about increased demand for alu-foil. At the same time, producers of converter foil have struggled to keep plants running efficiently with raw material shortages, worker shortages and more.

Then, adding to that, power shortages in Chinese factories continue to impact production of raw materials “foilstock” and converter foil, and a dearth of shipping containers and truck drivers to the equation. The collective impact has been enormous – a more than doubling of the ingot cost and much higher production costs, an average increase in transit times of more than a month, an astronomical rise in shipping costs, and significant instability and fluctuation, such that customers may be quoted only an estimated price when ordering, finalized at the time of shipment – the only point at which there is any certainty of costs.

The aluminum market has also evolved. As the world works towards a reduced carbon footprint and improved environmental conditions by replacing fossil fuels with renewable energy sources, alu-foil is now a key component of certain state-of-the-art batteries such as those used in electric vehicles, whose market is exploding. This specialized foil is hard to produce but carries premium pricing and better return on investment than converter foil.

The Political Landscape

Recent shifts in global politics are complicating matters further. The onset of the Russia-Ukraine war led to limits on Russian producers importing raw materials and exporting finished products – along with a global resistance to Russian products emerging and adding more uncertainty to an already challenging market. This gap cannot be filled by Chinese alu-foil producers, which are subject to anti-dumping duties in the EU, USA, India and other markets.

Shortages and tight supplies are expected periodically, but there is an ominous feeling that this current state of supply shortage is different and will not be disappearing anytime soon. In fact, it will very likely worsen before improving. It’s a perfect storm of grim conditions, in which flexible packaging manufacturers are forced to absorb continually higher prices even after making commitments to customers. They have no choice but to extend lead times and reduce supply to their customers. Most have no safety stocks of foil and are waiting for the next delivery to arrive.

Savvy converters understand that they will fare better with the right alliances, and they are therefore linking up with supply chain organizations – with decades-long working relationships across vast networks, only these entities have enough clout to evade the very worst of it.

The Force Multiplier Effect

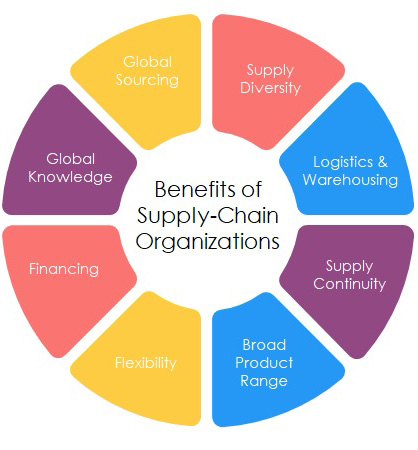

Working with a supply chain organization delivers multiple benefits to producers. Financially sturdy, supply chain organizations provide a cushioning that shores up the whole system. With stronger buying power, they are able to meet challenging payment terms, helping suppliers deal with their own challenges in sourcing requirements for raw material.

In terms of global logistics, vast networks of committed supplier relationships make a supply chain organization much more limber than any single entity. As well as being able to access untapped opportunities and even open global markets to producers that have previously been focused only on domestic supply, it can overcome regional geographic restrictions on imports from specific countries. And, of course, a supply chain organization also utilizes its own logistics network and vast experience to manage logistical challenges, creating elasticity that enables better efficiency, both by reducing the risk of reliance on a single source and by reducing product sourcing time.

Generally, converters who work with supply chain organizations are accustomed to ‘forward planning,’ and alu-foil producers are at maximum capacity prioritizing them. This extends lead times for others even more, but better safeguards those converters who are in the loop.

Furthermore, the warehousing capabilities of supply chain organizations enable converters to order and secure products for the future, optimizing their production plans and avoiding product shortages through their stock programs. In cases where alu-foil really cannot be acquired, or not in the right quantities or time frame, they can offer a variety of suitable alternative products, such as other high-barrier films that might be more readily available.

The Bottom Line

In these unprecedented conditions, alu-foil converters find themselves presented with critical challenges, decisions and also opportunities. Many have not established resilient supply chain models, so for those that have or still can, there is opportunity to take market share from their competitors. Supply chain organizations bring different tools and talents to the party, with a broader global knowledge and international relationships, diversity of supply, capacity allocations that are especially helpful in tighter market conditions and more. Those who manage for the long run likely already know this but many do not.

While some commercial climates reward the rogue spirit and ‘going it alone,’ we are living through a point in history when even the large, global players can best survive – and thrive – by linking with more extensive networks that provide them with greater strength, flexibility and alternatives. In hard times, joined forces will fare better than any one individual.

ABOUT THE AUTHOR

Lawrence Silverstein joined Now Plastics in 1997 as Executive Vice President and CFO, and since 2000 as one of the two shareholders. He has been CEO for over a decade and is responsible for all aspects of the company’s operations. Mr. Silverstein is a fully licensed CPA, has a bachelor’s degree in business administration and a master’s degree in Accounting, both earned from the University of Massachusetts at Amherst, Massachusetts.