Easy Open Application in Flexible Packaging: Snack N’ Seal

- Published: October 25, 2021

A move forward for Matix with its “snack n’ seal” resealable top packaging design which can help keep cookies fresh. Although folks in the baby products industry have used the idea before other applications, Kraft’s repurposing of resealable plastics layers was so innovative it won an award: DuPont’s 19th annual Gold Award in packaging for 2006. Here is what makes it award worthy:

A move forward for Matix with its “snack n’ seal” resealable top packaging design which can help keep cookies fresh. Although folks in the baby products industry have used the idea before other applications, Kraft’s repurposing of resealable plastics layers was so innovative it won an award: DuPont’s 19th annual Gold Award in packaging for 2006. Here is what makes it award worthy:

Tamper-Resistant

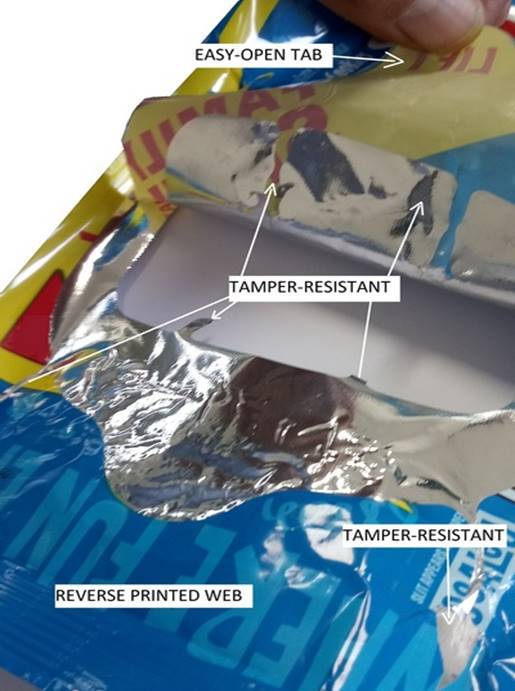

Packaging manufacturers face another problem aside from freshness: stores can’t sell cookies after the package has been opened. The packaging needed to be both tamper-resistant and resealable. When you pull the “easy open” tab, you can notice that the cutout for the resealable, sticky part of the top has two flange-type bits that scroll off to the sides. Those two thin strips of plastic break off as you pull the tab open to reveal the food inside, and you ca not get to the food without ripping off the thin plastic strips. That way, when you look at a bag in the supermarket, you can easily determine if someone has already tried to open it.

Less Waste

What makes it unique isn’t just that it’s used to keep the food fresh, any number of Ziplock bags could handle that task. Packaging manufacturers of the snack n’ seal took the packaging a step further and actually incorporated the resealable feature into the only layer of wrapping that holds the food in the container. This reduces excess packaging material, and therefore creates less waste.

Easy Closing

You do not have to make an extra effort to make sure the top settles back down evenly across the opening to securely close, because the plastic usually folds down right in place.

Adhesive for Reclosable Application = PSA Pressure Sensitive Adhesive (Reseal Adhesive)

Key Features: Provides a smooth, quiet and magnetic-like peel, FDA compliant for direct food contact applications. It’s repositionable, is a water-based adhesive. Pressure sensitive and formulated to provide a repositionable seal with little diminishment in seal strength provided there is no contamination of the PSA. PSA is also FDA compliant for use in direct food contact applications.

Seal strengths will vary with specific coating, film treatment and processing. High-peel resealable adhesive for direct food contact: FDA 175.320; Medium peel resealable adhesive for direct food contact: FDA 175.320.

How It Is Done

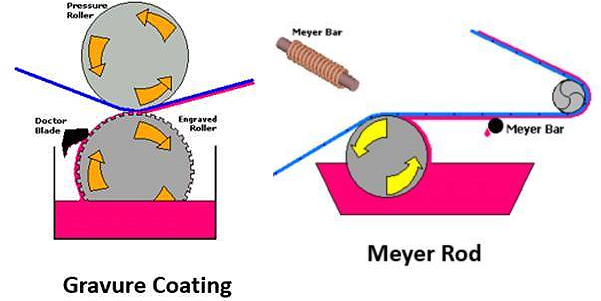

PSA Common Application Methods

Double Laser Scoring

Seal strengths will vary with specific coating, film treatment, and processing. High peel resealable adhesive for direct food contact: FDA 175.320; Medium peel resealable adhesive for direct food contact: FDA 175.320.

Laser scoring on reverse printed film side with particular shape for tamper-resistant + “easy open” tab. Additional laser scoring on sealant web side with smaller shape than the previous one, with tamper resistant geometry.

Result

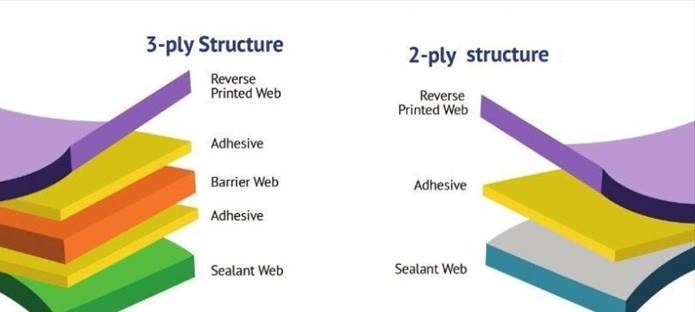

Two layers structure: PET + PSA Adhesive + metPET

Other Similar Solutions

Resealable Packages Using Labels

Apply labels to the film web to act as a resealable lid on the product package. The labels are produced with films, adhesives and finishes to deliver the desired barrier and structural properties for the finished package. Materials can be produced in both roll form or as individual pouches.

To create the openings for easy product removal, laser score the film creating an opening shape and size optimized to the package contents. The entire area of the laser scoring (what we call a slug) stays as part of the package and is secured in place by the label applied directly above it.

Zipper Bag, Slider Storage Bag

Made in plastic zip bag making machine. Laser scoring required, above zip position.

For more information, visit www.matik.com