Selecting the Proper Web Handling Equipment

- Published: December 11, 2023

By Bob Pasquale, President New Era Converting Machinery

Here we pick up on a discussion of the equipment sections that are required to allow for the proper handling and conveying of the web from section to section. Last month, we addressed tension control of the unwinding material and guiding of the web as it exits the unwind.

Splicing the Expiring Roll Onto the New Roll’s Web

The method of joining the end of the expiring roll’s web to the beginning of the new roll’s web is typically dependent on: The web materials and the process that the web is entering. To be considered are: The method of joining the webs, the type of splice to be formed.

The Method of Joining the Webs — There are several methods available to join the webs together such as: Pressure sensitive tapes or adhesives; heat and pressure activated tapes or adhesives; sewn splices; welded splices. The selection of the method of joining the webs is typically dependent on: The web material – what methods of joining the webs works with the particular web material; the process – what methods of joining the webs allow for the splice to survive the process conditions such as tension, moisture, heat.

The Type of Splice to Be Formed — The most common types of splices are: Lap splices – the expiring web’s end overlapping the new web’s leading edge; this is the easiest splice to perform; butt splices – the expiring web’s end butts up against the new web’s leading edge; this splice is more difficult to form, requiring more work and time to prepare/perform.

The selection of the type of splice to be formed is typically dependent on: The web material – what type of splice works with the particular web material; an example is a web with a liner that will later be peeled on a continuous basis, requiring a two-sided butt splice.

The process – what type of splice allows for the web to make it through the process; examples of this are conditions such as: The double thickness of web from a lap splice will not make it through the machine; a hanging tail from a lap splice may result in problems.

The design of the unwind should allow for the required splice to be formed. This could range from no hardware required for the operator to form a manual zero speed splice on the roll of web to the inclusion of a special splice assembly as shown on page 20.

How the Expiring Roll’s Web Will be Cut

During normal operation it is typical that the end of the expiring roll’s web, the beginning of the new roll’s web or both need to be cut as part of the splicing procedure. Several factors dictate the method of cutting and cutting hardware required including: The web material that needs to be cut; if the web will be moving or stationary during cutting; if the cutting will be manual or automatic.

Manual System — For some applications cutting of the web may be a simple task, performed manually by an operator using a handheld knife or scissors. Advantages: Extremely inexpensive equipment. Disadvantages: Safety is a concern; web must be stopped.

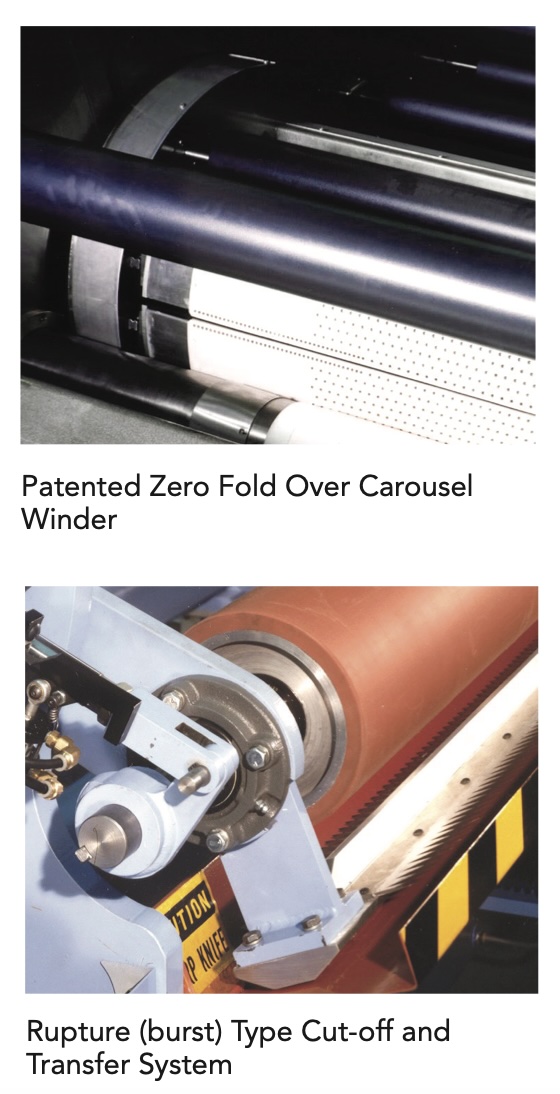

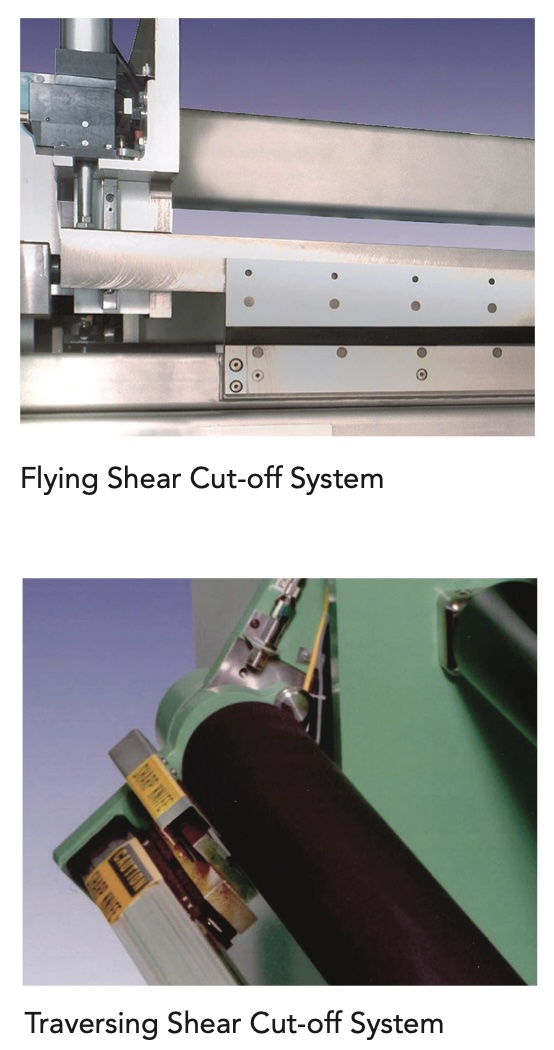

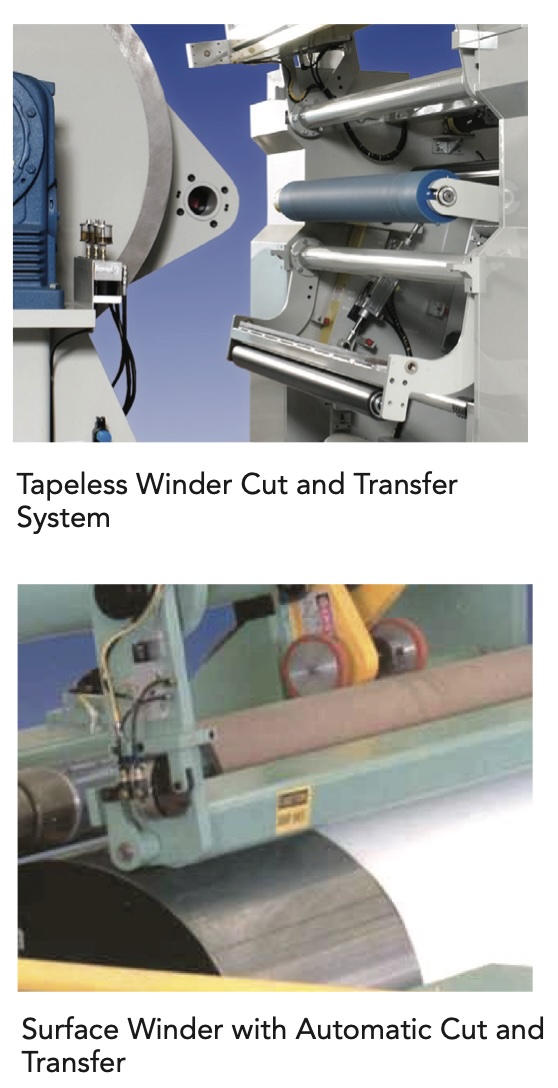

Automated System — An automated cutting assembly can be integrated into the unwind system. The design of the assembly can vary greatly as shown in the examples above. Advantages: Allows for cutting with minimal to no operator intervention; minimal safety concern; allows for repeatable cuts; certain methods allow for clean cuts. Disadvantages: Costly to install; take up space in the equipment line; requires higher maintenance; certain methods can generate debris; certain methods can result in unclean edges; certain methods can result in a biased edge if the web is moving during cutting.

Number of Unwind Positions

Of major consideration is the number of unwind positions that are included with the unwind. The unwind can be provided as a:

Single Position Unwind: An unwind designed to include a single assembly for holding rolls of web material. Advantages: Lower initial purchase cost; minimal space requirements. Disadvantages: Requires the process line to be stopped for roll changes; requires the process line to be stopped for splicing.

Multi Position Unwind: An unwind designed to include two or more assemblies for holding rolls of web material. Advantages: Allows for new rolls of web to be loaded into an unwind position and prepared for splicing without stopping the process. Disadvantages: Still requires the process to be stopped to safely splice the leading edge of the new roll to the end of the expiring roll.

Roll To Roll vs. Continuous Unwinding

For many operations it is not practical to stop the process line for splicing. In these applications the unwind system is designed to allow for the continuous feeding of web to the process by one of two methods: Allowing for the web to be fed to the process continuously while the unwind is stopped; providing a system that allows for the splicing of the new web to the old without stopping the unwind.

Allowing for the web to be fed to the process continuously while the unwind is stopped: Here a section such as a “J” box conveyor or web accumulator is incorporated into the process line. This section is designed so excess web can been stored in it for feeding to the process while the unwind is stopped for splicing. Advantages: Allows for continuous operation of the process while splices are being made at the unwind; particularly useful when time consuming splices such as sewn or welded ones need to be made without stopping the process. Disadvantages: Takes up floor space; may require a significant number of rolls to contact the web, creating scratches, static, stretching, etc.; does not work well with high-speed operations where significant storage time is required.

Providing a system that allows for the splicing of the new web to the old without stopping the unwind: Here the unwind is designed to allow for splicing of the leading end of the new roll to the tail end of the expiring roll without stopping the unwind. This type of system can take one of several forms but most typically features a turret unwind with an automatic splicing and cutting system. Advantages: Allows for the automatic splicing of new rolls at high speeds with minimal operator intervention. Disadvantages: Limited to lap type splices; only applies to splices that are per- formed using tapes or adhesives.

There are many different design considerations and decisions that need to be made when matching an unwind to a web process. Care needs to be taken to assure that the system is designed to maximize the operation of the process.

About the Author

Bob Pasquale is one of the founders and principals of New Era Converting Machinery, where he serves as President. He holds a degree in Mechanical Engineering from Stevens Institute of Technology and has worked in the web converting industry since 1985. He is the holder of several patents in the industry. Bob can be reached at bob.pasquale@neweraconverting.com.