How Research & Development Brings Practical Solutions to Production Problems

- Published: October 30, 2023

By Scott Warhover, VP Engineering, Mark Andy Inc.

Much development work is required to keep a company’s technology at the forefront of narrow web printing and converting. For the process of developing new technology and machines, of course the objective is to help customers become more successful. This requires a deep understanding of their needs and challenges, which certainly can evolve over time.

Companies must work with product management and sales departments to understand what customers say they want. This can also involve looking beyond the immediate market situation to provide something they don’t even realize they need yet!

Converters today have a far higher expectation of the technology and its capabilities — high performance is a given, but this now comes with an increased interest in sustainability. Both short-term and long-term market trends must drive your work. Long-term industry trends are the most difficult but critical to observe and predict, as they have the greatest impact on developments. That said, companies must remain flexible enough to allow customers to thrive through short-term trends as well.

One of the long-term trends we have all seen developing is toward shorter runs and more proliferation of label variants, personalization and customization.

While this has been influencing equipment development for several years, the shortages during COVID drove a short-term swing away from this, back toward fewer variants (SKUs). Our solutions need to allow customers to push the limits of new trends, yet still adapt to these changes.

The trend still driving the most change is the continued growth of digital printing in our market space. As with any shift in technology, there are a many new approaches fighting for a share of this market. I believe we will see this settle down somewhat in coming years as the most productive and profitable methods become established and accepted.

Print speed, cost and quality will continue to be the drivers here. RFID in labels and packaging continues to see growth, and I believe this will continue for quite some time. And, of course, owing to challenges in the work force and the global shortage of skilled personnel, everyone continues to experience the need for technology and automation to assist those operators with less experience.

There are two factors to a successful digital platform. As mentioned, the speed, cost and quality of the digital print is essential. But beyond that, the integration of the web transport and hybrid capabilities into these platforms is what transforms them into a complete and effective production tool. It is best to focus on both.

Also, incorporating developments such as sMArtlink into one’s products allows all machines to produce and gather productivity data, as well as store this information, provide the tools to analyze this data and communicate it effectively with customer ERP/ MIS systems.

Working with converters and brand owners on the development of new technology is key to the product development process. Everything is downstream of identifying customer needs. Working closely with them, both directly and through product management and sales, is essential to do so.

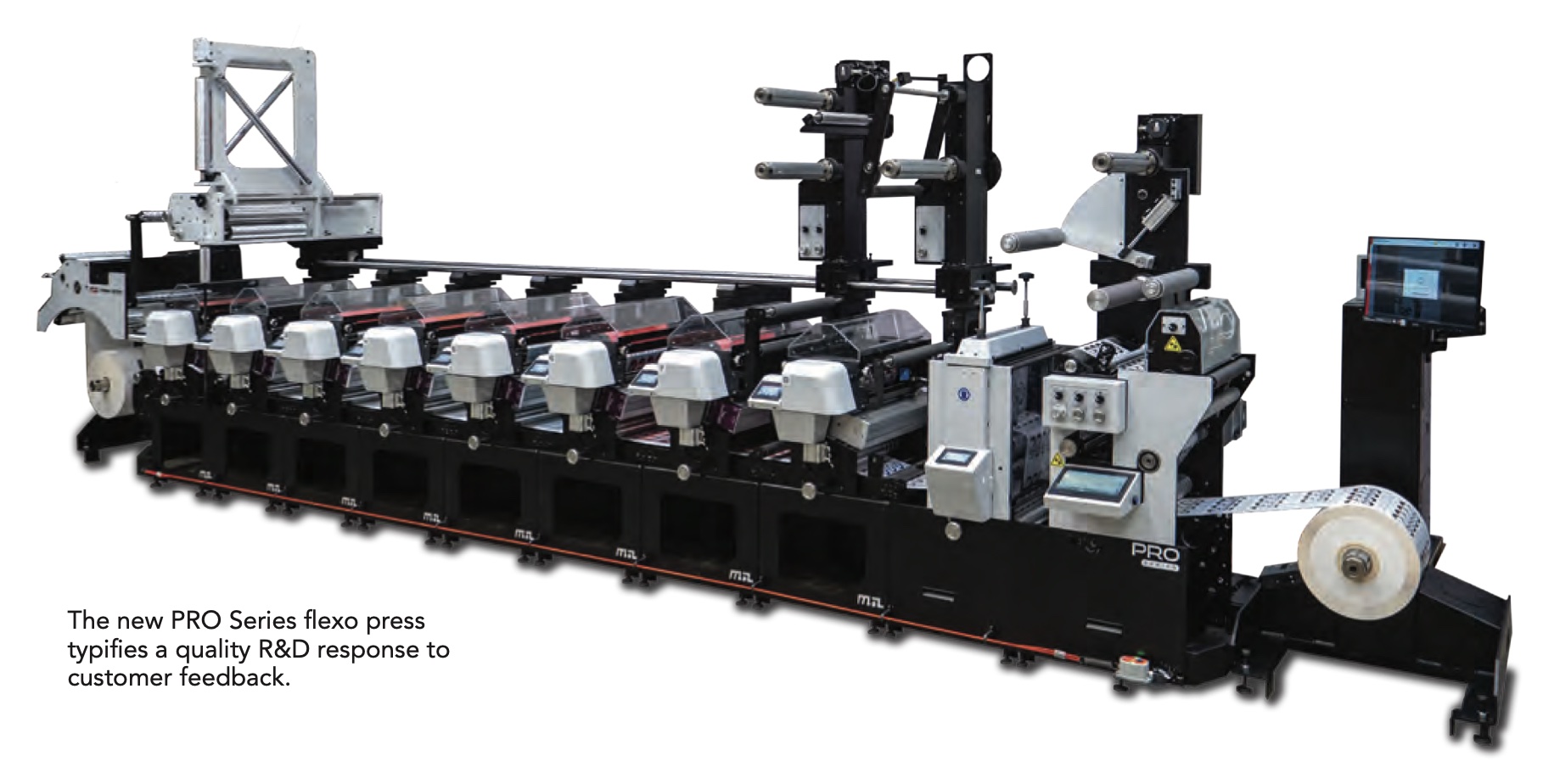

For example, say one converter customer asked for an affordable full servo press, while another indicated they needed either entry or mid-market digital capabilities, with the possibility of hybrid configurations. The response might be something like the Pro Series flexo platform, the first full flexo platform that can be built to run either left-to-right, or right-to-left, thereby fully enabling digital integration capabilities as well.

This merging of customers’ needs led to the development of something new, something beyond the original target, which allows one to offer both a full flexo solution and improve digital productivity and flexibility.

Looking Ahead

Over the next 10 years, narrow web flexo will continue as the high productivity mainstay of production. Flexo continues to produce the lowest cost and highest speeds for long run work, and the greatest flexibility for materials and converting inline. Customers need presses at the forefront of highest sales volumes, and continued development in flexo enhancements and new machines.

Also over the next decade, digital will continue to grow as we all see the cross-over point between digital and flexo continuing to rise. From a design standpoint, companies must still work on increasing production speeds and lowering per-unit costs to drive this trend further.

Variable data printing will continue to open new applications, and we will keep seeing improvements in the integration of digital engines to further gains in productivity, user friendliness and waste reduction.

Today and tomorrow, customers can benefit from companies that are not just flexo or just digital. An ability to develop digital engines and integrate digital engines do not have to be seen as separate press developments from flexo.

When a customer needs a machine, regardless of the printing technology, processes can be the same, and companies providing that make them a total solution partner to the industry. Look for a company that excels when faced with the most challenging applications and needs, regardless of the customization required.

About the Author

As VP Engineering, Scott Warhover participates in many aspects of Mark Andy, including the team that focuses on the development of new products, and the team designing each custom machine built for customers. Involvement in the design and technology decisions is a highlight of his job, along with managing the technology roadmap for future developments.