Flexible Packaging Machinery: Solutions for Change

- Published: September 16, 2021

By Dennis Calamusa, President and CEO at ALLIEDFLEX Technologies

By Dennis Calamusa, President and CEO at ALLIEDFLEX Technologies

As a prominent North American supplier of flexible packaging machinery and systems to a broad range of industries including food, snacks, beverage, personal care, and a multitude of other market applications, we enjoy a unique opportunity to gain an inside perspective working not only with the larger consumer product companies, but also the growing number of entrepreneurial start-ups with just a dream of success.

In our role in the supply of packaging machinery and secondary automation systems we also have the opportunity to work intimately with the supply chain who provide the vast array of innovative flexible packaging materials and value-added solutions that deliver the important consumer features that add functionality and convenience to the flexible package format i.e spouts, fitments, zippers, etc. These package enhancements provide the needed package functionality, safely and convenience with the goal of delighting the consumer and ultimately reflects in customer satisfaction and repeat sales.

Packaging is a strategy, and this is now truer than ever as companies compete for a changing and evolving mix of consumer preferences, changing demographics, as well as the incredible expansion of the eCommerce business. And flexible packaging is playing a major role in this packaging shift from traditional legacy packaging formats to new innovative flexible packaging.

To say the market is changing and so is packaging is an understatement. The days of depending on the same old package format is being challenged with a view toward “what’s next”.

Over the past decades many of the large multi-national consumer product companies have “become the package” that they have “standardized” on. Food companies have become “box” companies, “can” companies, “bottle” companies, etc. which has driven the company’s existing logistics and infrastructure packaging processes. As a result, many of these companies are reluctant and challenged to change due to the complexities of “change” due to their well-established and refined internal and external infrastructures straight through to the retail shelf which evolved over the past several decades, but packaging change is inevitable, and the transition is already dramatically under way.

This change dynamic is creating a unique strategic opportunity for the entrepreneurial market disrupters enabling them to step in with new packaging that is providing convenience, improved portability, and the unique ability to stand out on the shelf in the multitude of new marketing outlets all competing for the new consumer of today. In addition, flexible packaging can also reduce costs, simplify logistics and streamline the internal packaging process, all of which will be critical as we move into the future.

During the upcoming Pack Expo 2021 Las Vegas scheduled for September 27-29, we will see an array of new packaging machinery solutions that will reflect the changing packaging landscape and flexible packaging machinery will certainly be a highlight throughout this long-awaited exhibition.

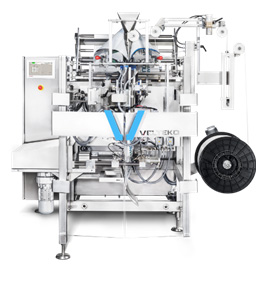

VELTEKO will debut their new Standup Pouch 360 model which they have “purpose engineered” from the ground up to specifically and economically produce popular high-quality standup / zipper pouches on-line from pre-printed rollstock. This system will enable packagers to package in-house utilizing economical rollstock as an alternative to more expensive pre-made bags.

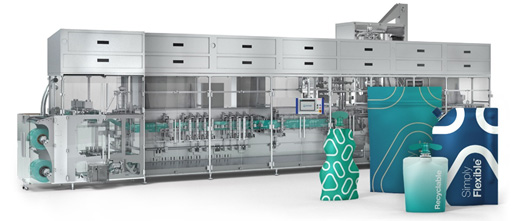

Spouted pouches continue to grow in popularity for a broad array of products including fruit puree, baby food, nutritional and energy supplements, beverages, personal and homecare, etc. Packaging machinery technology is now available to fill pre-made / pre-spouted pouches through the spout and cap or produce the complete package on-line from roll stock. The choice is now yours based on volume and budget. One of the biggest challenges in introducing a new packaging format is “getting started” and taking that “first step” by introducing that new package format to market before investing in higher speed, higher cost solutions.

The ALLIEDFLEX FLX SpoutFill Monobloc and Surdry Retort Pouch compact and economical processing machinery models offer packagers an automated “slower speed” alternative to get them started and on the road to successfully introducing a Flexible Packaging alternative. These machines are not only suitable for the smaller start-up company, but has also been a helpful tool for use in larger companies and institutions for pilot plant or laboratory packaging machinery solutions.

As volume grows, faster machines will be needed to accommodate shifting production demands from traditional packaging to a variety of innovative flexible packaging formats. This transitional growth will drive the demand for higher output machinery providing more flexibility with automated and improved “changeover” features and advanced servo technology to satisfy the changing and evolving markets which will continue to demand different package sizes, package formats and price points.

As we look into the future, we will continue to see new, fresh and exciting methods of packaging appear on a global basis. Since my perspective is based on innovative flexible packaging, I am continually providing my future insights as to why the flexible packaging category will continue to be the fastest growing method of packaging.

Flexible packaging is here to stay and will be further enhanced by the flexible packaging industry’s continuous commitment toward addressing environmental and sustainable concerns through the increased introduction of recyclable, bioplastics and compostable materials as our industry has the most to gain based on the numerous advantages that the Flexible Packaging format provides verses the traditional alternatives.

Walk the supermarket, aisle by aisle and witness the packaging shift first hand. A re-packaging evolution is underway . . .

About the Author

Dennis Calamusa is the president and CEO of ALLIEDFLEX Technologies, Inc based in Sarasota, Fla. He has dedicated the past 30 years of his career to the commercialization of the standup pouch and other innovative flexible packaging solutions in the North America market. For more information, visit www.alliedflex.com.