Three Common Types of Coating and Laminating Defects and the Methods of Inspection to Catch Them

- Published: June 05, 2025

By Tom Herold, VP of Sales for the Americas, Unilux

You're close to securing a new contract and the client wants to know more about your quality control processes. If you haven't already outlined your Quality Control measures and why they matter, keep reading.

Of course, every converter must be able to react to specific and common defects, whether via a trained operator or with high-end tools. Identifying these tools for the purpose of onboarding new employees or as a way to elevate your brand might just be a new way to look at it.

Here's a guide to the most common converting defects, paired with the technology available to catch them. Hopefully this will help you to identify the right technology to protect your reputation, and communicate that investment to your clients.

Surface Imperfections: Scratches, Bubbles and More

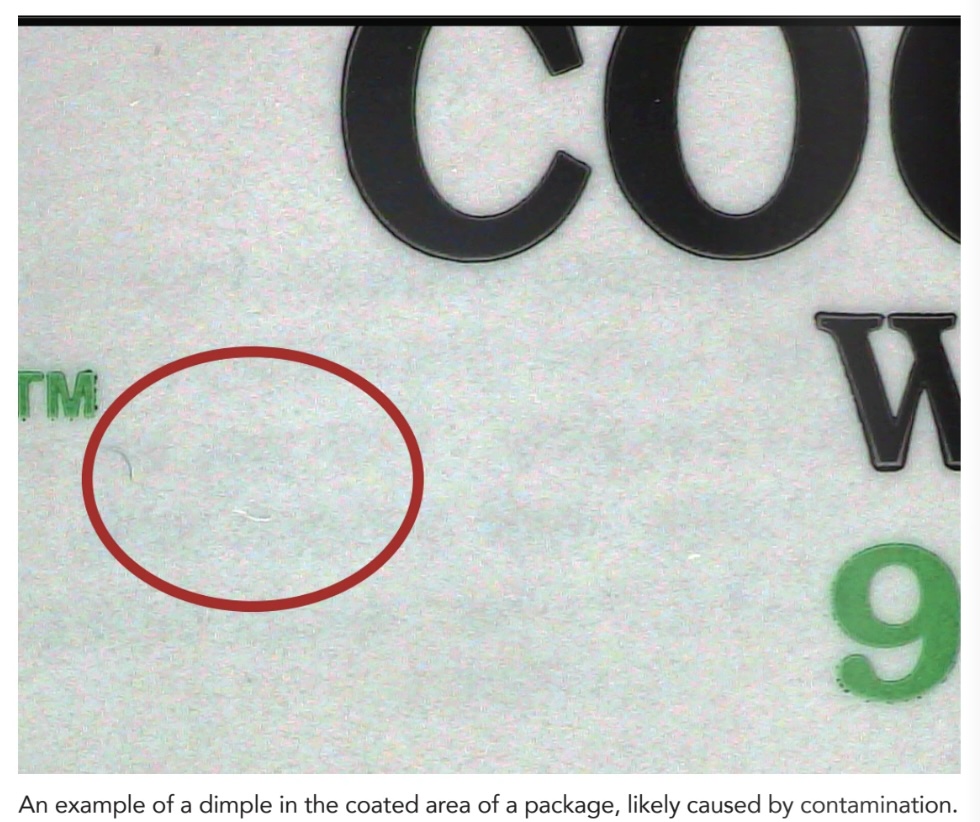

Surface imperfections can be traced back to two sources: contamination and process. Contamination is typically dust or particles embedded in the laminate or coating. These intruders can cause visible spots or affect adhesion. They can come from the environment or be introduced with a coating. Once in the process, these contaminants can be traced to a roll or any part of the process that touches the surface during coating or laminating. Here are three common surface defects, along with the technology best equipped to help you find each one:

- A common recurring defect in coating applications is pinholing, where a particle (usually dust) has plugged a cell in the applicator rolls. This defect can be seen with stationary strobes.

- Process misconfigurations are the primary cause of wrinkles. Wrinkles are best detected with an automated vision system due to the significant impact on the material and the inconsistent nature of the defect.

- Uneven coating can result in an orange peel texture, often due to incorrect drying conditions or coating viscosity. Changes in texture are difficult to see with the naked eye, therefore camera-based inspection, laser scanning, thermal imaging or optical profilometry are ideal.

Color Inconsistencies

Color shifts can be the result of variations in coating thickness, which can be traced back to mixing or application. Another common culprit is over-curing. Subtle fluctuations across the width of the process line can be seen immediately with a full-width stroboscopic system. Strobes are ideal for fast response time in this situation. An experienced operator can see shifts in color with the naked eye. An inspection strobe will help them identify where the issue is occurring.

If optical brighteners are present, a black light inspection strobe can be used for manual detection of coating defects. IR and UV cameras can reveal defects not visible to the naked eye. Hyper-spectral or multispectral imaging can also be efficient. A good example of this is the difference in varnish due to incorrect drying times or non-uniform application.

Edge Defects

Whether the material is slit or not, another defect to look for is edge quality. Edges that curl or lift after lamination can be caused by stress imbalances, incorrect temperatures or insufficient adhesive. In this scenario, a handheld strobe is ideal for the ability to inspect anywhere on the process line. If curling or lift is present, a strobe will temporarily stop the motion so that it can be properly identified and corrected without slowing production.

Camera-based solutions do exist for checking edge quality solely, however they are more often used on expensive materials where return on investment can be achieved quickly. In these situations, ROI is typically reached in a matter of rolls.

A Recap of Inspection Technology

In summary, every coating and laminating production environment requires some form of visual inspection for maintaining quality and detecting defects early. Most methods are often used in combination, with automated systems providing continuous inspection and manual checks providing additional quality assurance at critical stages.

Method: Manual Visual Inspection

Defects: bubbles, streaks, scratches, wrinkles, color inconsistencies.

How it works: Inspection strobes are timed with the speed of the web, allowing the human eye to see objects moving at high speed as if they are standing still.

Hand-held magnifiers or microscopes allow inspectors to view finer details of the coating or laminate surface for better defect identification.

Method: Automated Vision Systems

Defects: surface imperfections; scratches, bubbles, dents, material thickness and uniformity.

How it works: Camera-based systems capture high-resolution images processed with algorithms.

3D vision systems provide depth information to detect imperfections on three-dimensional surfaces, which is especially helpful in complex shapes or textured coatings.

Note: For stroboscopic and camera-based inspection, infrared (IR) and ultraviolet (UV) lighting is helpful in capturing defects not visible to the naked eye.

Method: Laser Scanning and Profilometry

Defects: surface waviness, variations in thickness, roughness and other textural abnormalities.

How it works: Lasers create a high-resolution map of the surface by reflecting light.

Optical profilometry uses light interference to detect finer details, which is helpful for quality control in high-precision coatings.

Hyperspectral and Multispectral Imaging

Defects: contaminants, inconsistencies in chemical composition, uniformity, color accuracy or color shifts that could signal defects.

How it works: Hyperspectral imaging captures a wide spectrum of wavelengths for each pixel on the coated surface, allowing for detailed chemical analysis.

Multispectral imaging captures fewer spectral bands, making it an effective method of identifying specific defects faster.

Thermal Imaging

Defects: coating thickness variations, bubbles or poor adhesion.

How it works: Thermal cameras detect temperature variations across the material surface.

Optical Coherence Tomography (OCT)

Defects: internal defects and layer uniformity, particularly in multi-layer coatings.

How it works: OCT uses infrared light to capture high-resolution, cross-sectional images of the coating layers.

About the Author

Tom Herold has been in the converting industry for over 35 years. He began his career in the ownership capacity for WTI, Sales Management for Maxcess and Accraply, and now at Unilux as VP of Sales for the Americas. Unilux provides QC Inspection solutions for web processes in multiple markets. Unilux inspection solutions are built on 60+ years of experience serving the world's harshest manufacturing environments. Tom's vast experience in the converting industry allows him to speak on web inspection converting, coating and laminating processes.