Tension: The First Thing We Must Get Right

- Published: April 15, 2024

By Neal Michal, Principal, Converting Expert, LLC

Web tension is arguably the most important parameter for any web process. Tension is the first thing we must get right.

What Tension?

Selecting the right tension for your process will facilitate improved productivity and delivered quality. A general guideline is to tension the web to 10-25 percent of its elastic limit. This requires knowledge of your web properties. (Refer to my previous articles that describe the importance of material testing: PFFC April, May and July 2022.)

If your tension is too low the web will sag and will not track properly. Wrinkles may appear due to poor lay flat. If the tension is too high, stress induced troughs may form in open spans. Web breaks may occur during poorly controlled speed changes. High tensions will neck down delicate webs due to Poisson. Proper tension control is critical for coating, laminating, slitting and winding.

Tensioning Methods

There are several tensioning methods to choose from. The two most common are velocity control (Draw) and tension control. It is a best practice to use draw control for stretchy webs and tension control for stiff webs.

Brakes, clutches, cylinders or motors are used to provide tension. Slow speed processes that require high tension will often use brakes. Medium speed / medium tension processes may use clutches or differential shafts. Festoons and dancers often use cylinders to provide tension. Processes that require higher performance for speed, tension or acceleration will use variable frequency AC drives (VFAC) or servo motors.

Feedback Options

Feedback options for velocity include motor encoders, surface contact wheels and laser doppler velocimeters. Diameter sensors are required to convert rotational speed (RPMs) to web speed on an unwind or center winder.

Master Speed Reference

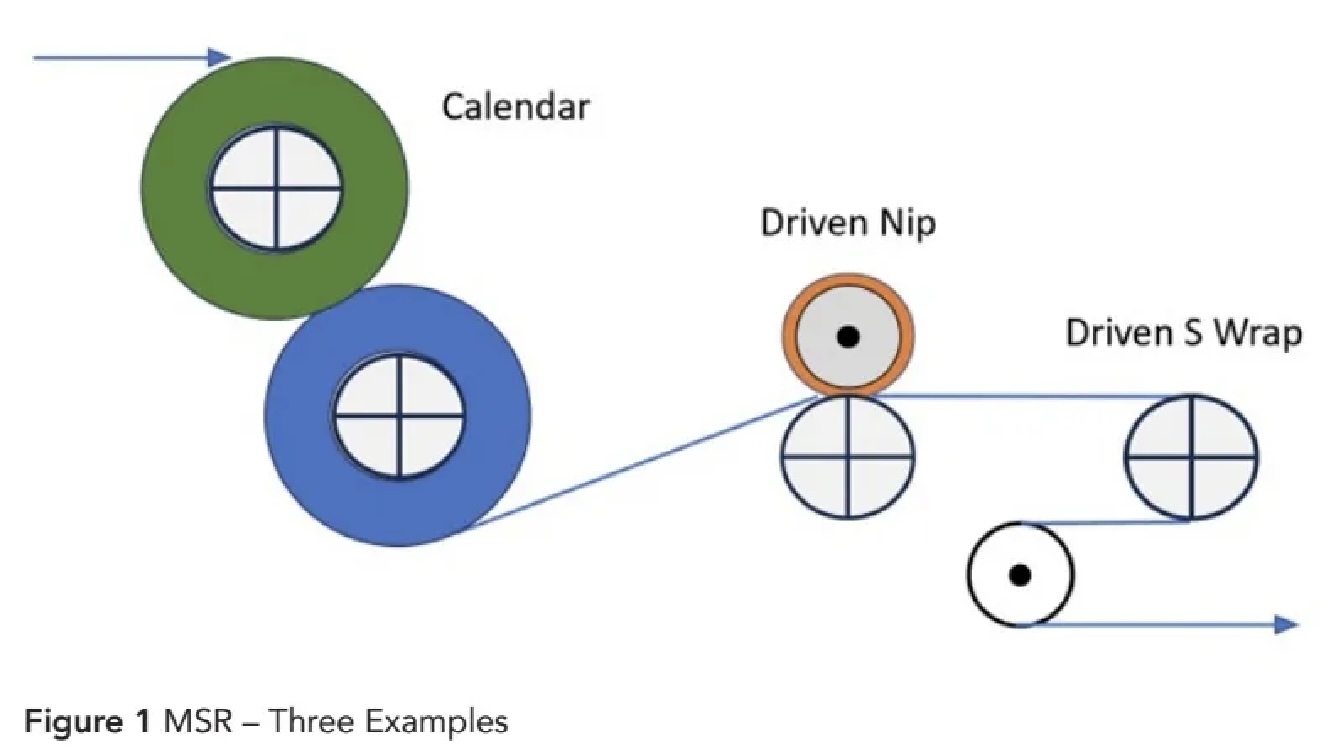

It is important to document how the process is tensioned and controlled. Well-designed processes will designate a Master Speed Reference (MSR) based on what is important to control. The MSR is often the driven section with the largest inertia such as a calendar roll. Think of the MSR as the heartbeat of your process. The web should never slip across the MSR. A driven nip or 5-wrap can also be designated as the MSR as long as there is no risk of slippage (Figure 1).

Tension Zones

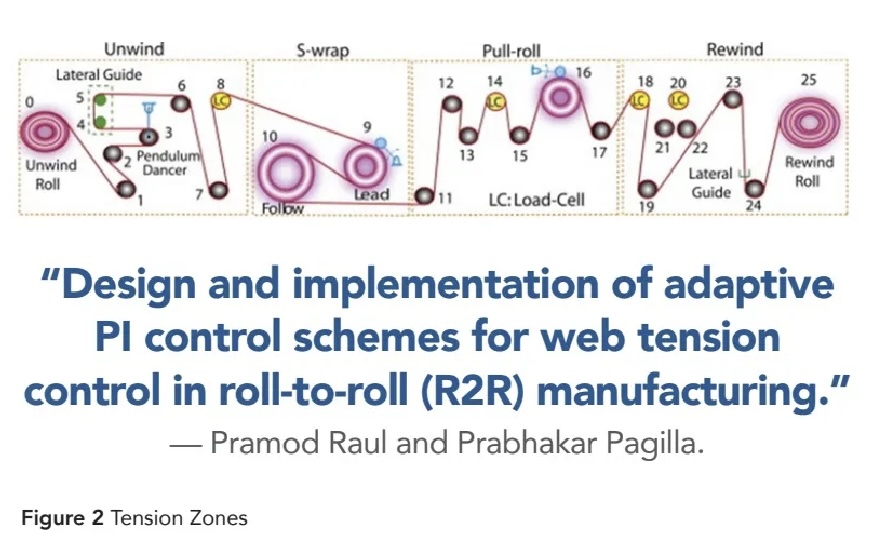

Tension zones are established between consecutive driven elements such as an unwind, nips, S-wraps and winder. It is a best practice to document your tension zones using a web path drawing. Number all of the rollers in the process with descriptions for what they do (Figure 2).

Highlight feedback devices and what they point to. It is common to mix tension control methods. A braked unwind with diameter feedback is an example of closed loop torque control. This may be followed by several velocity-controlled sections (draw). A load cell may be used for closed loop tension control at the winder.

Let's discuss the two most common tensioning methods.

Velocity Control (Draw)

Velocity control is often the low-cost solution to control a web process. This is often referred to as draw control. Draw control does not isolate or control tension.

Draw will only increase or decrease the incoming tension from the upstream tension zone.

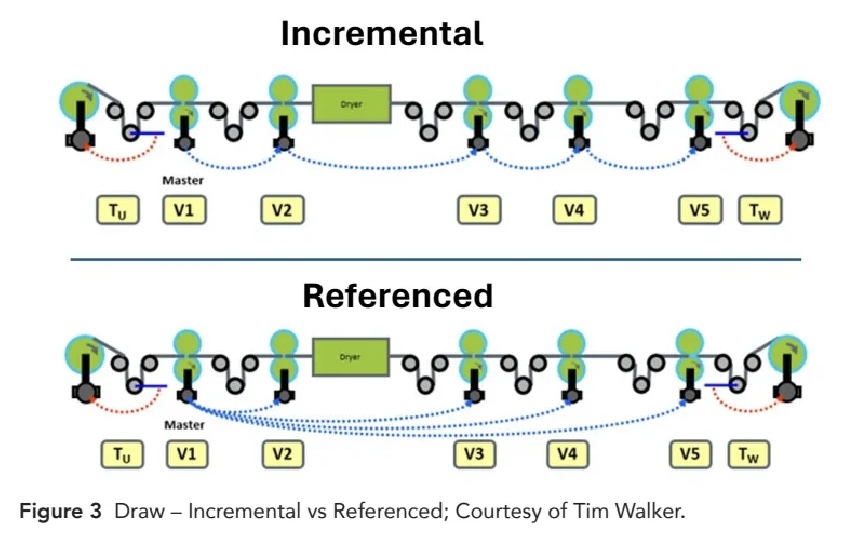

There are two types of draw control: Incremental & Referenced (Figure 3). Incremental draw modifies the velocity of a driven roll based on the velocity of the previous roll. Referenced draw controls the velocity of driven rolls based on one referenced roller. This referenced roller is most often the Master Speed Reference (MSR).

The tension in a specific zone is the web strain x modulus x width x thickness. Draw is an equipment parameter defined by the velocity of the driven rollers. Strain is a web property defined as the change in elongation from an unloaded condition (AL/L).

Tension Control

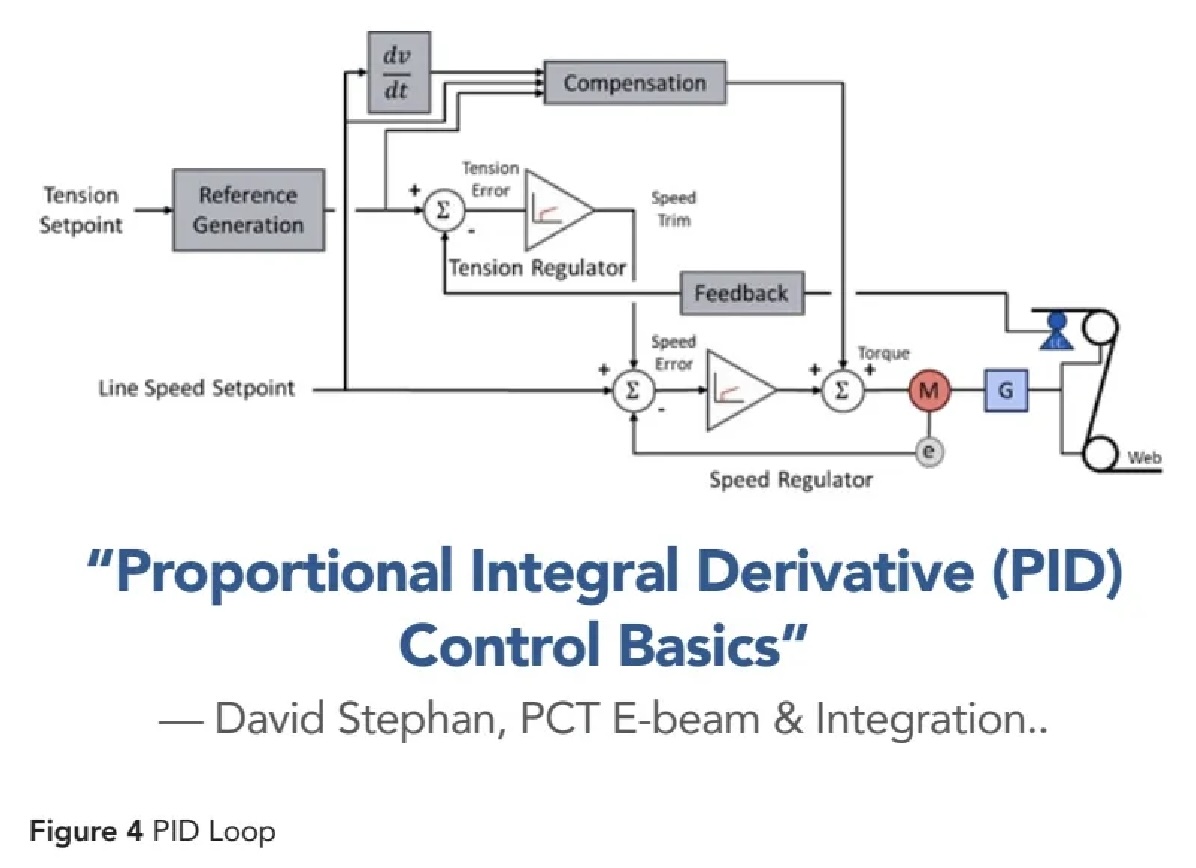

Tension loop control requires a load cell or a dancer with additional programming in the control software. A well-designed tension control zone begins with velocity control (draw). A "PID loop" is used to "trim" the velocity of the driven roller using feedback from the load cell or the dancer position (Figure 4). The amount of trim is typically 5-10 percent.

Dancers

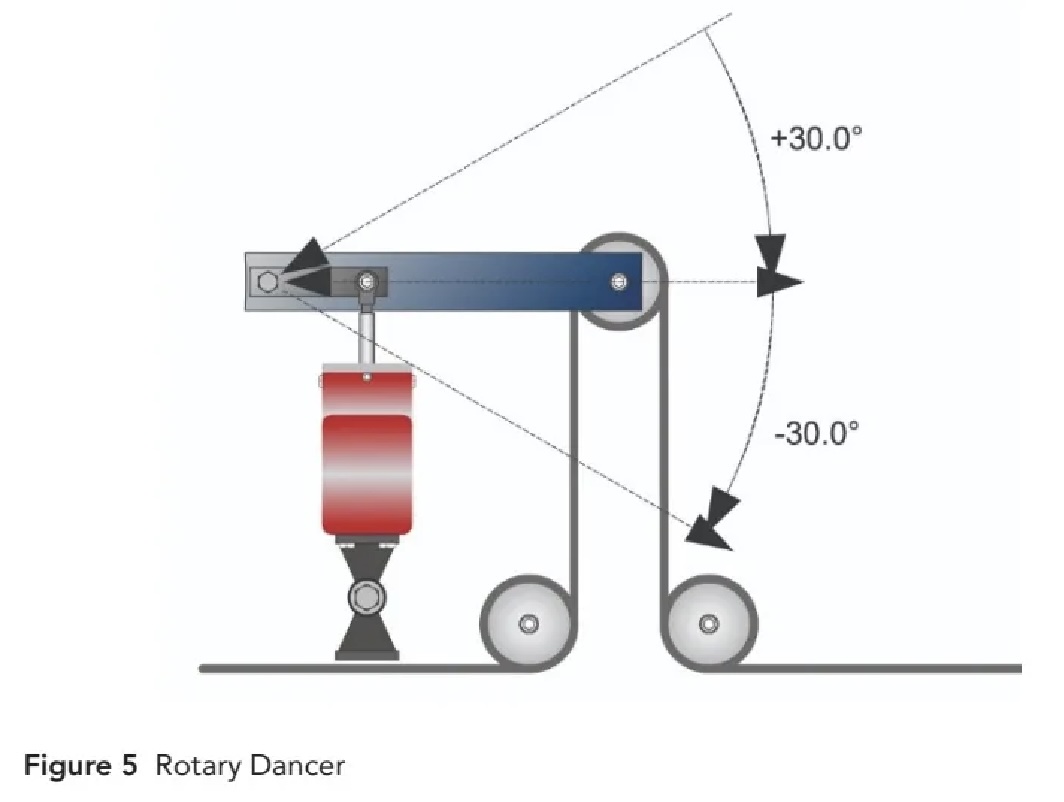

There are two common dancer designs: Rotary and linear. Rotary dancers pivot an idler on an arm. The arm can be mounted horizontally or vertically. Horizontal orientation is common (Figure 5). Vertically down eliminates most of the gravitational effects from the mass of the roller and arms.

Linear dancers move an idler in one plane, typically in the vertical direction. They are used when more capacity is required compared to a rotary design. Linear dancers may be designed such that the rotational inertia of the idler matches the translational inertia of the dancer assembly (Figure 6).

For most web converting applications, the dancer (either design) is loaded against the web using pneumatic cylinders and a pressure regulator. The air pressure and the geometry of the mechanical design determine nominal tension.

The position of the dancer is monitored by an encoder. A PID loop adjusts the velocity of a driven section upstream or downstream of the dancer to control the position to setpoint.

In strict technical terms, a dancer is in closed loop position loop control. Tension is controlled in open loop. The actual web tension will deviate from nominal due the dynamics of dancer while it is moving. A poorly designed dancer can display large unintended tension disturbances. Well designed dancers will control tension within +/- 5 percent.

Dancers vs. Load Cells

Both dancers and load cells can be used to successfully control a process. If you need to know actual tension, a load cell will be required.

In order to actively control tension, the load cell will be used to trim the velocity loop. The load cells should be selected based on the anticipated web tension.

Dancers are ideal for processes awhere some compliance will help your process run smoothly. Load cells can be added to a draw control process if one needs to know actual tension.

Conclusion

Web tension is arguably the most important parameter for any process. Tension is the first thing we must get right. It is important to document how the process is tensioned and controlled.

Document your tension zones using a web path drawing. Establish a master speed reference that will not slip. Select tension based on your material properties and your process requirements. Use draw control for stretchy webs; tension control for stiff webs. Both control methods may be present on a web line.

Dancers are in closed loop position control; actual tension will vary due to dynamics. Use dancers for processes that require some compliance. Linear dancers can provide more accumulation than a rotary dancer. Load cells are required for closed loop tension control. Load cells can be added to any process and are required to document actual tension in a specific zone.

About the Author

Neal Michal of Converting Expert is a well-known authority in web handling, process design and optimization. He worked with the Web Handling Research Center for 20 years. Currently serving as a technical advisor with The Association for Roll-To-Roll (ARC). He can be reached at neal@convertingexpert.com or through www.convertingexpert.com.