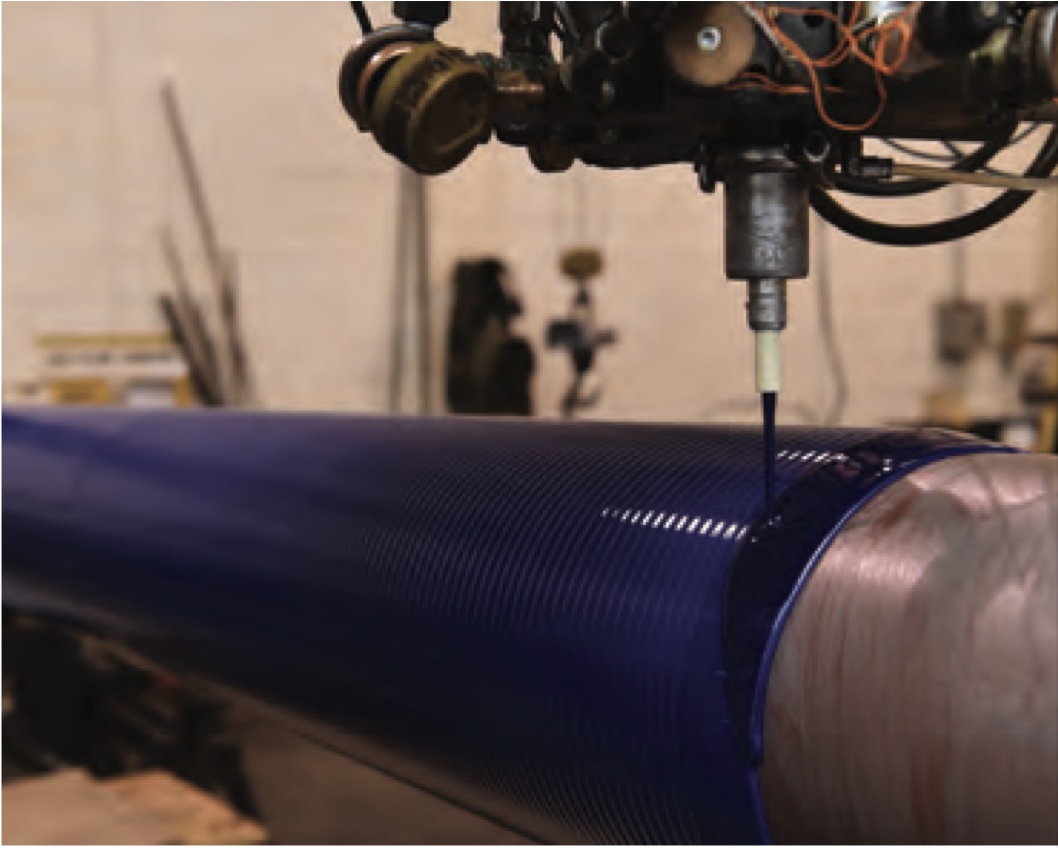

New Elastomeric and Urethane Roller Coverings?

- Published: November 02, 2023

By William R. Bradley Jr., Vice President, Business Development, American Roller Company

In the converting industry there are many machine roller positions that rely on elastomeric or urethane coverings to produce high-quality products. For decades, there have been limitations with specific coverings used, often a trade-off with durability, temperature thresholds, and chemical resistance. Often, multiple performance values are required.

In the converting industry there are many machine roller positions that rely on elastomeric or urethane coverings to produce high-quality products. For decades, there have been limitations with specific coverings used, often a trade-off with durability, temperature thresholds, and chemical resistance. Often, multiple performance values are required.

With the hundreds if not thousands of covering formulations available in the market- place, the application dictates the family of polymers used. For example, if a web substrate is being laminated with a high-temperature coating (350-400F), a product in the silicone family is usually selected. With this covering there is a trade-off where durability, compression set, and abrasion resistance can be a compromise.

In the last few years, there have been new developments in covering creation, blending the strengths of each formulation to produce next-level compounds. For instance, urethane coverings are used in high wear and abrasive applications, however, offer no release properties from adhesives or other chemicals. Today there are urethane formulations offering incredible release properties without giving up their abrasion resistance qualities.

If you are battling an application using the same roller covering for years, there could be a better option. Ask your current supplier or contact a new one and ask, “What is the latest technology?”