Release Liners: A Worldwide Special ReportReducing Silicone Mist

- Published: November 01, 2002, By Loretta A. Jones & Paul C. Vandort, Paper Industry Group, Dow Corning

Part 1 | Part 2 | Part 3 | Part 4 | Part 5

In the early 1980s, machines that applied silicone release coatings ran at speeds of 300–600 fpm (100–200 mpm). While they could produce mist, it was not a regular occurrence. Some of these coaters are still operating, and with upgrades, can run at 700–1,000 fpm (230–330 mpm). Many newer coaters are running at 1,500 fpm (500 mpm), and the latest can achieve 2,000–2,500 fpm (650–800 mpm). It is virtually impossible to configure equipment so it does not produce mist at these speeds.

Mist Generation and Measurement

The primary application methods for silicone release coatings are multi-roll coating heads—typically five-roll, smooth roll—and three-roll differential offset gravure (OSG). Both produce mist.

While OSG dominated early installations, most high-speed coaters installed recently have been outfitted with five-roll, smooth roll coating heads. When it comes to mist generation, neither method has an advantage. The phenomenon of mist generation occurs at points of film splitting under high shear: The higher the line speed, the more mist is generated. Clouds of fine mist can be seen billowing from the nip between the applicator and backing roll, where the web is traveling between them. This mist often can be seen following the web path into the ovens—where it creates oven dus—as well as spraying outward horizontally. This is the mist that usually is referred to and can cause issues with worker exposure and equipment contamination. Not so obvious is the spray of (usually larger) mist particles from the back of the coating head setup. It can deposit on the backside of the liner and cause problems with subsequent converting operations.

As this problem has become more of an issue, the ability to measure it has evolved. While it is necessary to minimize contamination of equipment and materials, worker exposure is the primary concern. There are no established regulations specifically regarding silicone mist exposure, but a generally accepted guideline is that used for airborne contaminants. Several techniques have been used to assess the amount of mist generated. The values obtained, and the methods to measure them, differ from the Industrial Hygiene guideline and accepted methods for measuring worker exposure. Every method has shown some utility but also some limitations. Each attempts to distinguish mist by particle size, since those particles of 5 microns and smaller are considered respirable and thus pose the highest risk to coater operators.1

During early explorations, the PC-2 Air Particle Analyzer2 was used. Generally referred to as a cascade impactor, its guiding principle is the separation of particles by size by depositing them on different crystals connected to a mass sensor, providing valuable comparative measurements. It has been invaluable in evaluating silicone systems, but in the field, some difficulties are encountered.

The Aerosizer DSP3 also has been used. It operates on the principle of aerodynamic time-of-flight analysis. However, it, too, can yield misleading data collected in an environment of dense mist.

Another technique used for trials is Industrial Hygiene air monitoring. Air is pumped through a cyclone device that draws it through a filter at a calibrated rate. The filter is pre-weighed, and the change in weight from the various operators’ devices is compared to a blank device placed in a similar environment. This method can be used on stationary points on coating equipment and via a personal detection device. Workers wear a small plastic canister attached near the head, connected to a hand-sized pump attached to their belt, for eight hours as they move through their day. Attachments can be used to collect data on total or respirable mist. This method is accepted by Industrial Hygienists worldwide.

“Controlling” Mist

There are four options at an operation’s disposal to control mist that can and are used in various combinations. Three are aimed at reducing mist at the point of source, while the fourth is designed to remove generated mist. The removal or extraction of mist from a silicone coating head—while successful at reducing worker exposure—only moves the mist in another form to a different area. Exhaust tubes or channels placed at the coating head route the mist through filters and into the plant or outdoors. The filters can become clogged in areas of heavy mist and must be changed often to be effective. This method is not to be discounted, however, as supplemental to other methods when mist already is reduced greatly.

Large enclosures are added to contain mist within a reduced area, and operators spend little time in these areas. Walls, ceiling, and floor of the enclosure rapidly become coated with silicone, so this approach does not solve the problem of equipment or web contamination or slipping hazards.

Equipment manufacturers have attempted to design coating heads less likely to generate mist, but with wider coaters and higher line speeds, this becomes more difficult without compromising quality and efficiency.4 Experiments have been conducted to determine the impact and relative importance of silicone coat weight, line speed, roll ratios, and nip impressions on the amount of mist generated. While there are conditions that help minimize mist generation, line speed is the overriding factor.

For new installations, larger-diameter rolls go a long way toward reducing the line speed at which mist generation will begin.

The selection of a silicone system primarily is dictated by the desired release force and then tailored by formulation to meet cure requirements. Dow Corning set up an enclosed station to generate and study mist, using a two-roll mist generator5 and the PC-2 analyzer for measurement. Lab studies showed the relationship between mist generation and silicone polymer viscosity, which was later correlated on pilot and production coaters. This data not only shows higher viscosity polymers probably will generate more mist at a lower line speed, but even very low viscosity polymers eventually will mist under certain conditions.

In order to offer a range of products to meet a wide spectrum of customer and industry requirements, Dow Corning chose to approach mist reduction through the development of an additive.

The first-generation product, introduced in 1995, dramatically reduced the amount of mist generated. In practice, however, it proved to have a negative impact on other performance properties. After laboratory and pilot coater evaluations, Dow Corning began to work with customers in 2000 to evaluate second-generation materials on coaters. Syl-Off 7137 HSXL and Syl-Off 7138 HSXL have been in commercial use for about 12 months now.

Product Characteristics and Performance

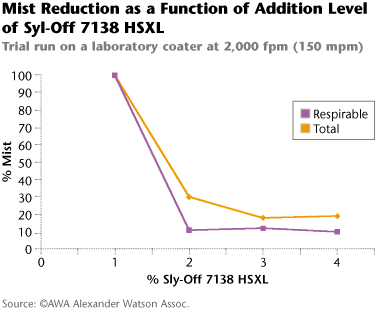

The two materials represent both types of silicon hydride cross-linkers used in paper release coatings today. Syl-Off 7137 HSXL is based on a homopolymer, while Syl-Off 7138 HSXL is based on a copolymer cross-linker. The recommended use level is 1%–4%, with typical use levels expected to be in the range of 1%–2% to reach the desired level of mist reduction (see graph above).

For formulating purposes, additional standard cross-linker is recommended to reach the desired silicon hydride/vinyl ratio. Laboratory and pilot coater studies have been conducted to evaluate the effect of the use of these products on various performance properties. For the purposes of evaluating the effect on cure and pot life, the high end-use level (4%) was tested. The results showed that no impact was observed on either cure or pot life.

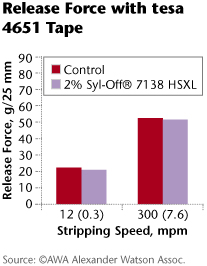

Since the main function of these coatings is to provide release, it is imperative the impact of the high-speed cross-linker on release is understood. There is an almost infinite number of combinations of release coating formulations and adhesive types, substrates, silicone and adhesive cure, and storage conditions that could be considered. For this reason, however, standard tapes are used for testing release. The graph at the right shows no change in release was observed when tested at 12 ipm (0.3 mpm) and 300 ipm (7.6 mpm) stripping speeds, with 2% Syl-Off 7138 HSXL. Although no difference was observed in this testing, it is important each customer evaluates materials and constructions to determine if formulation adjustments are necessary.

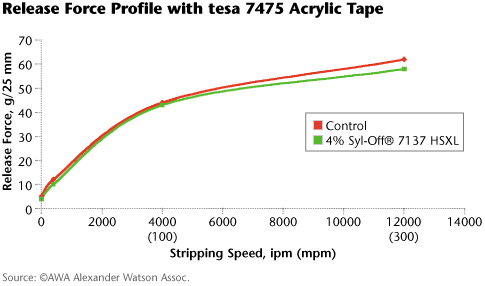

Additional testing at a wider range of stripping speeds also was done with the acrylic tape. A slight difference was noted at the highest stripping speed, but this was only with the highest recommended level of high-speed cross-linker. (see graph below)

A Cost-Effective Solution

Productivity and cost reduction will continue to drive new products and new technology in the self-adhesive industry, and the use of a high-speed cross-linker is a cost-effective solution to reduce mist during the application of silicone release coatings, without affecting other key performance properties. The impact is observed at the coating head but also is characterized by reduced operator exposure to mist, improved coater hygiene around the coating head, and reduced requirement for cleaning ovens and other equipment. As a result, productivity can be increased and waste decreased.

REFERENCES

1American Conference of Governmental Industrial Hygienists, Particle Size-Selective Sampling in the Workplace, Report of the ACGIH Technical Committee on Air Sampling Procedures, Cincinnati, 1985.

2California Instruments; Sierra Madre, CA 91024; 626/355-3361.

3TSI Inc., Particle Instruments/Amherst; Amherst, MA 01002; 800/335-5577.

4L. A. Ostness, "How to Maximize 5-Roll Transfer Coater Performance," Black Clawson Tech Tips No. 5, May 1998; blkclawson.com

5P.C. Finney, "Fluid Flow Software Simulates Forward Roll Coating Process," Packaging Technology & Engineering, April 1996.

6Tesa is a registered trademark of Beiersdorf AG, Unnastrasse 48, D-20245, Hamburg, Germany; +49-40-4909-0.

Lori Jones graduated from Bowling Green State Univ. of Ohio with a bachelor of science degree in chemistry. Since 1985 she has held a Technical Service and Development role at Dow Corning serving the Paper Industry Group in the areas of pressure-sensitive adhesives and release coatings.

Paul Vandort received bachelor of science degrees in chemistry and biology from Hope College in 1988. He then worked for three years at the GE Corporate R&D Center. In 1997 Paul received a Ph.D. in organic chemistry from Purdue Univ. and joined the Paper Industry Group of Dow Corning Corp.

Part 1 | Part 2 | Part 3 | Part 4 | Part 5