Medical Patches | Faustel Meets Challenge of Hydrogel Pad Production

- Published: October 25, 2017

Engineers a new coating line and custom slot die for Katecho Inc.

Iowa-based Katecho, a full-service contract manufacturer specializing in medical and cosmetic products, has perfected the production of hydrogel-based pads for use with a variety of medical devices. This includes single-use, sticky pads used with monitoring electrodes, such as EEG and EKG devices. It also includes wound dressings for treating first-response injuries.

Katecho’s latest hydrogel pad production required a unique and entirely custom solution. From controlling gel thickness and subsequent shrinkage, to introducing a supporting scrim between a top and bottom liner, the custom coating solution required multiple trials and tweaks to achieve the desired specifications. Even then, producing a wound roll of gel had its own set of challenges.

This article captures Katecho’s unique production challenges in pursuit of product excellence in hydrogel pads for medical applications, and the unique technology and machinery that came to yield world class products.

A Mission of Excellence

“Katecho” is a Greek word meaning “to hold” or “contain” … a good connotation for a company that intended to manufacture hernia mesh products and now produces patches that “contain” pharmaceutical drugs and specialty gels.

The company was launched in 1984 by Lorne Scharnberg in a rented 4,000 sq ft space in Des Moines, IA. Due to the long development times for hernia mesh products, Scharnberg began researching other opportunities. The focus soon shifted to transdermal patches and hydrogel pads.

While the company beginnings were quite modest, Scharnberg’s focus was clearly a mission of excellence. “How can you be the best and also unique?” he asks, and then answers. “By having a first class manufacturing operation, and by applying the technology and converting equipment that makes you unique. For that, he adds, “get the absolute best equipment — the Cadillac in the industry.”

That philosophy has paid off. Today Katecho serves an international customer base from its 166,000-sq-ft Des Moines facility, now employing some 465 people.

Not Your Common Coating

Hydrogels are a water-based mixture with a gel-like consistency. Katecho has engineered more than 30 different hydrogels, most specially formulated to meet the unique performance requirements of each application and medical device. Others are designed for use as first-response wound dressings.

To ramp up hydrogel production, Katecho wanted to double web widths to 23 in. all while maintaining a tight tolerance coating thickness run to run of 0.001 in. The process required applying a hydrogel solution to a Mylar web, introducing a nonwoven scrim web to provide structure to the gel, curing the hydrogel, cooling the web, and finally adding a another polyethylene web as a top liner before slitting and winding into manageable rolls.

Katecho knew this could only be achieved with highly engineered, custom coating machine. According to Scharnberg, “The ‘Cadillac’ solution came from Faustel, a Wisconsin-based manufacturer of custom coating, laminating, and winding machinery.” Engineering the perfect process, however, was anything but simple or conventional.

The new coating line was built at the OEM’s facility, but testing and refining would have to be done at Katecho. Once installed and tested, the real production challenges would surface.

Hydrogel Challenges

When applied to the base web, the hydrogel shrinks in width while increasing in thickness. This starts from the edges of the laydown and works its way inward until the scrim is introduced. The support of the scrim helps to stop this undesirable process. Consequently, the coating thickness had to be varied across the width to accommodate for the gel’s physical changes. A conventional comma coater would not work.

Faustel Project Engineer Sam Gely Jr. spearheaded the machine development and subsequent modifications. According to Gely, “Hydrogel material clearly presented a coating challenge. After examining how it changed through the curing process, we determined the ideal coating method was a custom slot die that could be adjusted for casting variable thicknesses at the outer edges.” The coater was engineered and built back at the OEM’s facility and then installed on the new machine at Katecho. Gely adds, “Trial runs and adjustments were made onsite to finally achieve the ideal casting — a slightly wider coating, also thinner by 0.008 in. at the outer edges. This countered the undesirable characteristics of the gel and the end results were within the customer specs.”

A scrim material was introduced next to embed in the hydrogel and give it structure. Running the scrim web required its own handling challenges, Gely pointed out. “Too much tension would stretch this nonwoven mesh-type material causing it to ‘neck down.’ This narrowed our operating window for a tension range.” This required lower range tension load cells.

With the new tension cells applied, this tension zone was able to operate at the needed high resolution control of 1.2–1.3 lbs. Operators can adjust this tension to a fraction of a pound via a touch screen HMI.

Such processes do not allow for high speed production. Running at 450 in./min was very acceptable in achieving the exact quality output Katecho wanted. Lower speeds, however, affected the web guiding. Web guides are used with each of the three unwinds, before the laminator, and on the rewinder.

The loop response between the edge detectors and the web guides was being thrown off, causing the web to oscillate. The systems needed to be “dialed down.” Wisconsin-based web guide OEM, AccuWeb, provided the original web guiding systems. They responded to the problem by providing the proper response parameters that could be adjusted through their Micro 1000 controller. Infrared-type edge detectors also proved highly effective in sensing the edge of the porous scrim web.

The Cure

Once cast with an embedded scrim web, the “wet” hydrogel is cured using a series of UV lamps. Connecticut-based Electro-Lite Corp. provided the UV curing stations consisting of four lanes down length of the web with 13 lamps per lane.

Each bank contains special 400 watt UV bulbs suited to curing the specific hydrogel chemistry. Bulb intensity is not varied — they operate either in a “full on” setting or in “stand-by” mode during non-production times. A sensor runs down the length of each UV lane to make sure each is generating the amount of UV energy desired.

According to Katecho Production Director Chris Gunsaulus, “Ultimately, the desired state of hydrogel curing is achieved through control of the web speed.” Operators perform tests and trials in order to establish the ideal parameters. ”The entire UV curing section stretches twelve feet,” Gunsaulus adds, “and that adds a significant amount of heat to the entire web.”

The Cool Down

Before final winding, the web needs to be cooled down from the heat of the UV lights as well as the heat energy generated by the hydrogel as it cures. Gely points out, “Too high of web temps can negatively impact the poly film liners, causing them to distort, resulting in deformation of the wound rolls.”

The first stage of web cool down is achieved with a custom-engineered “cooling plate” that recirculates cooled liquid through embedded coils. Heat energy is removed from the web as it slides over the plate.

Following the cooling section, the final top poly liner is laminated to the coated web. The web then travels over a large heat transfer roll (often call a chill roll) to remove more heat energy prior to the final winding process.

To conserve floor space for Katecho, Faustel designed the custom unit with unwinder and rewinder at floor level and the coating and cooling sections in an elevated position above.

Winding Up a Gel Roll

The original machine was designed for continuous winding of single rolls. The rewind section employs a turret design that rotates a new core into winding position as the active roll reaches its target size. Most continuous winding operations use a knife-driven system to cut the web during the transfer action. According to Gunsaulus, this wasn’t practical on the hydrogel line due to low web tensions.

Instead, a traversing knife system is employed. During web transfer, a cutting knife traverses quickly across the web making a clean cut. The cut web is applied to the new core where double-sided tape has already been applied.

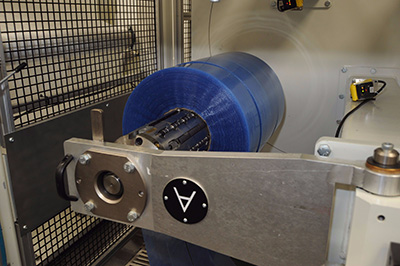

Not long after start-up of the new machine, Katecho wanted to add a slitting section to wind three separate rolls. Here again, the low web speed prevented the use of conventional shear-type slitting systems. Instead, a crush-cut system from Tidland proved most effective. A blunt-edge knife rides over the web, pinching the web apart as it is presses against an anvil plate underneath.

Winding rolls of a gel coated web also presented some unique challenges, Gunsualus pointed out. “Too much web material with not enough tension in the wound roll would cause the roll to deform under its own weight,” he stated. “It could also deform more easily during handling once off the machine. As a result, the winding tension window was very narrow. Wound roll sizes are typically limited to 250 ft of material depending upon customer specifications.

The Wrap Up

Katecho also added a custom-designed pneumatic manipulator from Iowa-based Positech Corp. to remove the heavy rolls from the winder. The unit’s arm positively locks onto the rewind shaft so operators can safely transfer finished rolls onto the manipulator arm. The manipulator then positions rolls vertically or horizontally for protective wrapping, palletizing or transfer to another converting operation.

Some of Katecho’s hydrogel rolls are shipped to customers who perform additional converting. Some customers look to Katecho to fully convert, package, ship, and even inventory ready-to-use product. None of the finished products carry the Katecho name.

As far as Katecho CEO Lorne Scharnberg is concerned, “It’s all just part of running a first-class operation.”