Emerging Trends Steering Label Making Towards Sustainability

- Published: September 25, 2023

By Alaina D’Altorio, Marketing Specialist, Smith Corona Labels

Consumers nowadays take great consideration about the impact goods they purchase have on the environment. This has led to a growing awareness of sustainability in all things commerce — and labels are no exception.

Because labels play such a crucial role in the global supply chain, the label industry is setting goals to reduce its carbon footprint with more sustainable alternatives. They’re also aiming to meet customer needs and expectations with greener options.

However, it’s not just the final product that matters. Each step of the label manufacturing process has its own effects on the environment as well.

Whether it’s saving energy and reducing emissions, improving safety with transportation, responsibly sourcing raw materials or providing alternative label products for recyclability purposes, the label industry is pushing for a more sustainable supply chain while creating a better label in the process.

Energy Efficiency with UV Curing

Label manufacturing from start to finish can be a lengthy process. Not to mention one that requires an abundance of energy. One area this rings true is during the silicone curing process.

Typically, the most common way to cure silicone is by using thermal heat. Laminators run silicone-coated release liners through large ovens that generate high temperatures (around 200 degrees Fahrenheit) for the necessary chemical reactions to take place.

Unfortunately, these ovens utilize natural gas, which generates large amounts of energy and releases harmful emissions into the atmosphere. These volatile organic compounds (VOCs) include pollutants like carbon, nitrogen and sulfur, and pose a risk to both human health and the environment.

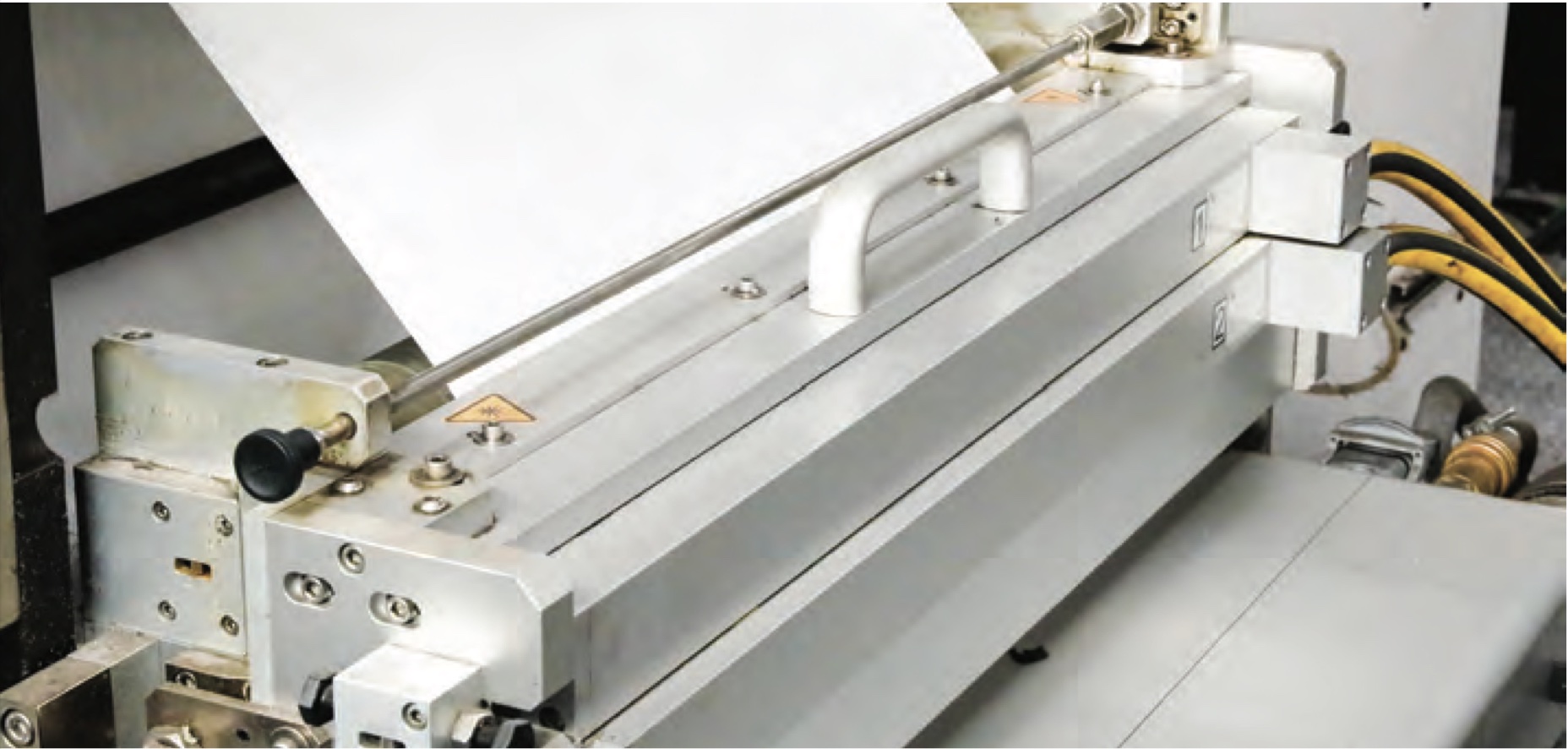

However, curing silicone through ultraviolet (UV) light is a method that is gaining traction. Un- like traditional drying methods, UV utilizes electricity instead of heat.

This reaction instantly cures the silicone, resulting in a reduced production time. More importantly it can result in significant energy savings up to 75 percent when compared to thermal methods. UV curing also releases fewer harmful emissions into the environment.

As an added benefit, UV curing provides more reliable and consistent results with label release as well as increasing durability and gloss characteristics for film materials.

Sustainability Through Transportation

Sustainability with label manufacturing doesn’t just extend to the product being made in the factory. Transportation of key materials to the company also has its effects on the environment.

Take the previously mentioned UV curing process. For this method to work properly, a highly pure nitrogen gas must be used – 99.999 percent to be exact. Typically, label manufacturers will have this hazardous material delivered via truckloads.

However, depending on the company size, this results in bulk deliveries occurring weekly or even daily. The frequency of these deliveries increases the amount of harmful CO2 released into the atmosphere.

One remedy to enhance sustainability in this instance is through the addition of an on-site gas production system. By producing nitrogen gas on-site with the right equipment, the need for nitrogen truck deliveries decreases substantially. The result is a significant carbon footprint reduction.

While this process is unique for label manufacturers, it represents one of the most effective ways label manufacturers can scale their business in a more sustainable manner.

Responsible Sourcing of Raw Materials

Deforestation is still a pressing global issue that continues to have negative environmental impacts. A 2022 McKinsey report stated that each year around 10 million hectares of land are cleared — that’s the size equivalent of South Korea.

For label production, paper is still the leading material used for both facesheets and release liners. So it makes sense to install sustain- ability initiatives where it all begins: Harvesting the raw materials.

To meet greener goals, many pulp and paper companies are taking initiatives to responsibly source exactly where their raw materials come from.

Using materials from local forestries that will replant trees after harvesting is one way to do this. One paper company claims it plants four trees for every one that is harvested to curb deforestation. This way natural resources are not depleted and suppliers can set responsible expectations for what they’re taking.

Other companies utilize teams of foresters to help protect resources. These hired personnel work closely with landowners to determine appropriate timber harvesting as well as requirements for future reforestation.

Recyclable Release Liner Alternatives

The life cycle for many label products is a short one. Because most quickly find their way into the trash, recyclability is essential for a smaller carbon footprint. Take release liners...

Around 87 percent of U.S. release liner consumption is paper-based. However, each year hundreds of thousands of tons of paper liners sit in landfills and add unnecessary waste to the environment. This is due to the difficulty separating the silicone coating from the facesheet.

Options promoted as fully recyclable by many in the label industry are film liners. One example of this is polyethylene terephthalate (PET), mostly due to it being the closest alternative to paper liner.

PET liner is thinner and produced with a significantly less silicone coating, which enables a more efficient recycling process.

After its use, the liner can be ground up and molded for reuse as various plastic items.

Zero waste release liners are also gaining attention in the industry. These alternatives are made of biodegradable and compostable materials, like plant fiber, and undergo a natural decomposition process when they reach the end of their life cycle.

In total, these options reduce the amount of waste sent to landfills for much greener practices.

The Future of Label Manufacturing is Green

As a growing number of organizations, businesses and consumers embrace environmental responsibility, we can expect to see significant advancements in the sustainable production of labels. These eco-friendly initiatives provide optimism that the future of label manufacturing will not only enhance product quality, but also contribute positively to the health of the planet.

Sources:

About the Author

An industry innovator, Smith Corona Labels provides high-quality labels to end-users at the lowest cost possible thanks to their unique vertically integrated system. As the Content Marketing Specialist for Smith Corona Labels, Alaina D’Altorio is responsible for writing and discussing topics on their blog relevant to all things label related: Industry news, material shortages, trending innovations and more. She can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it. or through www.smithcorona.com.