Data in Detail

- Published: October 01, 2006, By Edited by Claudia Hine Managing Editor

Production Monitoring

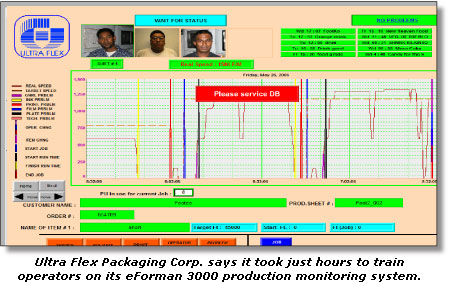

Ultra Flex Packaging Corp. is a technology-driven printer, laminator, and converter of flexible packaging. After installing an ICU eForman 3000 real-time production monitoring system, it realized a significant reduction in downtime on two Fischer & Krecke Flexpress 10 flexographic presses, a Schiavi solvent-based laminator, and two Titan slitters.

The eForman 3000 reportedly allows Ultra Flex to monitor production equipment and processes effectively, pinpoint errors in production, and take swift corrective actions. Production managers have the opportunity to monitor and measure production in real time, even while seated in their offices.

The data is converted into easy-to-read graphs and charts that reveal trends and allow comparisons of historical and current data.

Eli Blatt, president of Ultra Flex, says, “What distinguishes the eForman from other monitoring systems is that it is the most elegant yet simplest solution we found, after a thorough search, for effective data collection and production monitoring. Installation took less than a day, and operators were trained in just hours. Now, production managers can glance at a screen and quickly see if a press or slitter is running at desired speeds or how long the machine has been down.”

The core functions of the eForeman 3000 system are the abilities to monitor, collect, and transmit valuable production data from any machine through easy-to-read graphics. The system takes away the complexity of gathering and analyzing real-time speeds and downtime information and is designed to fit digitized, analog, and non-computerized machines.

Customized Configuration

Ultra Flex has configured the eForeman 3000 to display the optimal required speed for a specific job, while comparing it to the actual speed at which the job is being run. Web tension is noted, as is the length of downtime. The production history of any job can be retrieved and appropriate comparisons made. The system can be run on an ICU network, thus allowing several managers to view real-time data simultaneously. At Ultra Flex, the data retrieved also is used to cost completed orders.

VP of printing Zalman Zohar says, “I can monitor several machines at the same time. Having access to such real-time information enables me to mobilize resources so problems can be tackled swiftly and downtime reduced. Having eForeman is like having a vigilant supervisor assigned to each machine at all times.

“Every morning, production managers and supervisors review and compare performance by shifts. They are able to see how much downtime was experienced and the reasons involved. Not only has this been an incentive in stimulating healthy competition between shifts, but flaws in equipment or production techniques are easily identified and addressed.”

Zohar adds the eForeman 3000 took away the gray areas, the guesswork, and the wondering. “Now we know,” he says, “and we know in real time. It is amazing the positive impact this technology has had on our productivity.”

Now Eli Blatt starts his workday with a review of detailed and reliable productivity and efficiency reports. He likes to call it his “report card” on each shift, each machine, and each operator.

“It is strictly a matter of dollars and cents. There is no doubt that this real-time technology has driven productivity and profits upwards,” he says.

Blatt admits that the eForeman 3000 data collection system does not replace the human operators at a machine. “Their input and advice continues to be invaluable. But now I can trust and verify.”

CONVERTER INFO:

Ultra Flex Packaging Corp.

975 Essex St., Brooklyn, NY 11208

718/272-9100; ultraflex.com

SUPPLIER INFO:

ICU eForeman/The Provident Group —PFFC-ASAP 308. providentgrp.com

Fischer & Krecke —PFFC-ASAP 309. scher-krecke.com

Schiavi/Bobst Group — PFFC-ASAP 310. bobstgroup.com

Titan/Bobst Group — PFFC-ASAP 311. bobstgroup.com