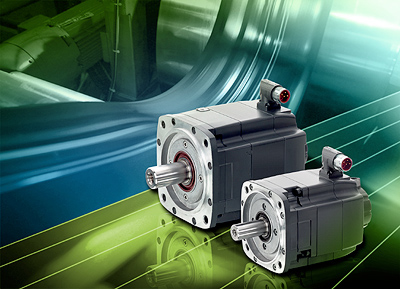

NEW HIGH-INERTIA 1FK7-HI SERVOMOTORS ADDED TO SIEMENS OFFERING

- Published: January 01, 2021

Siemens Industry, Inc. has announced that it is expanding its popular 1FK7 servomotor family, with the introduction of a new high-inertia style. The higher rotor inertia of this design makes the control response of the new 1FK7-HI servomotors highly robust and suitable for high- and variable-load inertia applications, including the feed and auxiliary axes on machine tools, as well as winders and unwinders on converting, packaging and printing equipment.

Siemens Industry, Inc. has announced that it is expanding its popular 1FK7 servomotor family, with the introduction of a new high-inertia style. The higher rotor inertia of this design makes the control response of the new 1FK7-HI servomotors highly robust and suitable for high- and variable-load inertia applications, including the feed and auxiliary axes on machine tools, as well as winders and unwinders on converting, packaging and printing equipment.

These self-cooled 1FK7-HI servomotors provide stall torque in the 3 Nm to 20 Nm range and are offered in IP64 or IP65 with IP67 flange degree of protection, with selectable options for plain or keyed shaft, holding brake, 22-bit incremental or absolute encoders, as well as 18 color options.

A mechanical decoupler between the motor and encoder shaft protects the encoder from mechanical vibrations, providing a long service life. In cases where the encoder needs to be exchanged, the device automatically aligns the encoder signal to the rotor pole position, enabling feedbacks to be changed in the field in less than five minutes.

These new Siemens 1FK7-HI servomotors also feature the unique Drive-Cliq® serial bus and electronic nameplate recognition, allowing virtual plug-n-play operation when paired to the Sinamics® S drive platform. All servomotors in this new line are also configured to interface with Siemens Sinumerik® CNC technology for machine tool applications and the motion controller Simotion® for general motion control use.

Selecting the proper motor to suit the application is facilitated by the Siemens Sizer® toolbox and compatible 3D CAD model-generating CAD-Creator package.

For more information, visit www.usa.siemens.com/motioncontrol.