Precision Slitting Sets Converters Apart

- Published: March 07, 2019

By Susan Stansbury, Contributing Consultant

Precision slitting specialists go beyond the basics of slitting large rolls and rewinding into smaller ones. They stand apart from the typical role in the slitting-winding community.

Precision slitting specialists go beyond the basics of slitting large rolls and rewinding into smaller ones. They stand apart from the typical role in the slitting-winding community.

A number of factors, from the range of substrates handled, to sophistication of equipment, to targeted markets all contribute to a converter’s reputation as a custom, precision operation.

At American Custom Converting, Gary Forehand talks about exacting parameters to deliver top-notch results that customers expect in their contracted converting situations. For example, the slitting target may be at 1/64” rather than 1/32’ plus-or-minus tolerance.

He notes that the substrate and end-use, final product, can dictate tolerances. American Custom Converting handles a specialty range of substrates from board stock to lightweight tissue, from laminates to nonwovens.

At Contract Converting, Bob Saari states, “Tight tolerances are becoming a very critical aspect for converting many specialty substrates right now. Products in various markets are being engineered so that only tight specifications are allowed for end use.”

Saari points out that narrow cuts and specialized roll diameters are sought after “quite frequently.” He says, “Customers are looking for the ‘perfect match’ when choosing an outsourced slitting partner.”

This also explains why there are many specialty slitting-rewinding companies in Wisconsin, Illinois and throughout the Midwest. There are many custom variations available, often paired with other in-house capabilities such as laminating, coating, flexographic printing, folding and value-added packaging.

OFFERING “SEAMLESS” SERVICE

OFFERING “SEAMLESS” SERVICE

From initial custom work, plus other converting steps, converters can stand out. Saari states, “Slitting a customer’s substrate is not the only thing precision slitting companies do these days. They offer the ‘mirror effect’ which means the outsourced slitter company can now mirror getting their customers’ products slit, labeled, packaged and shipped as if it came from their own facility.”

HOW DOES SLITTING OCCUR?

It’s a basic question. According to Saari, there are the typical “standby slitting methods including shear, score and razor technology. The diversified materials used in the making of blades along with engineering of them have seen improved results in recent years.” In addition, he says that center-lining specialty machines for enhanced slitting helps customers in downstream finishing operations. The latest equipment and associated supplies often tell the story when customers check out facilities.

Custom converters tend to supply markets including labels, tapes and the ever-growing flexible packaging arena. Production of items like “smart labels” with RFID make expertise a “must.” La customers are frequently brand-leading commercial giants ranging from 3M to P&G.

These product groups often require more complex combinations such as laminated substrates and multi-step cutting and converting. For example, slitting may occur prior to printing and afterwards before further conversion, often at another facility. For example, a specialty tape can incorporate a release liner, adhesive and exterior layers with printing between layers, barrier properties and more.

WEB HANDLING PLAYS A KEY ROLE

According to industry expert and teacher David Roisum, web handling is at the forefront in precision outcomes: “Web handling has been an essential tool to reduce waste, delay and customer complaint for 200 years.” He speculates on the future of specialty converting: “What will the next two or 20 years bring? We can use extrapolation to anticipate a continued decline in R&D and print publication, but the demand for skills training will continue unabated.” This means that skills in the custom slitting industry will play a major role.

According to industry expert and teacher David Roisum, web handling is at the forefront in precision outcomes: “Web handling has been an essential tool to reduce waste, delay and customer complaint for 200 years.” He speculates on the future of specialty converting: “What will the next two or 20 years bring? We can use extrapolation to anticipate a continued decline in R&D and print publication, but the demand for skills training will continue unabated.” This means that skills in the custom slitting industry will play a major role.

Outcomes in slitting and web handling are often determined by substrate properties including web thickness and strength. Substrate suppliers need to deliver on their own tight materials tolerances.

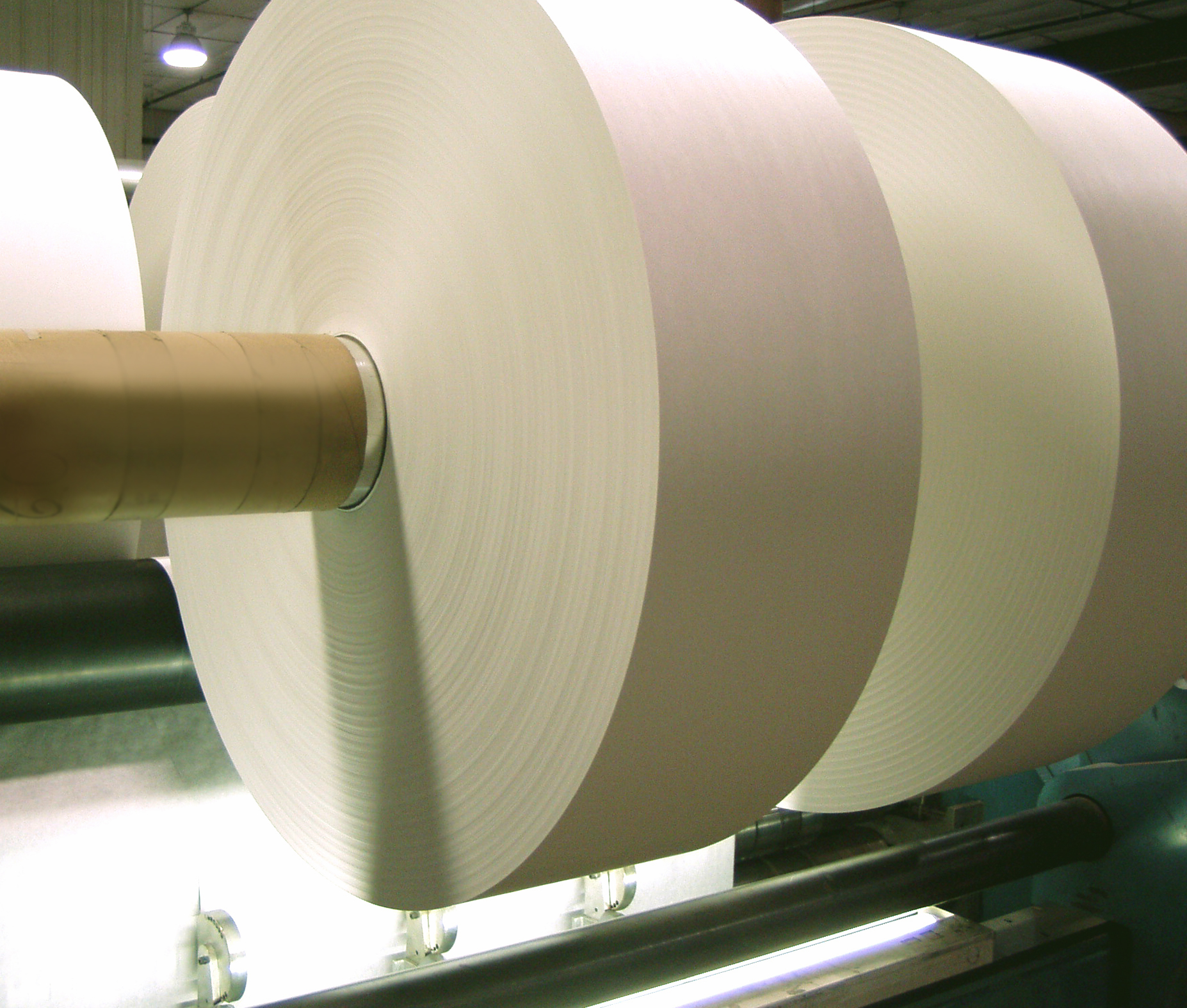

Value-added work by converters in slitting and related operations has meant continued growth and success over recent years. Compared to slower-growth and lower profitability of many in the “mill roll” substrates business, such as various paper mills, these converters are increasingly out front.

While many are still quiet contract partners, others such as Mondi Group are presenting themselves more like their commercial customers. They talk about careers, sustainability and public-relations generated news. It’s a sign of what’s happening in the custom converting world.