A Guide to Selecting the Optimal Water-Based Primer for Extrusion Coating and Extrusion Lamination Applications

- Published: November 29, 2021

By Jessi Spadaccino, communications manager at Mica Corporation

When trying to manufacture structures with multiple layers, a chemical primer is usually needed to improve bonds between a substrate and a coating, such as an extrudate, or ink. Primers can also help to enhance barrier properties, aesthetics, and overall performance of the finished structure. Water-based primers are a common choice because they provide superior performance on a vast array of substrates and are generally a safer and more sustainable choice compared to solvent-based primers. However, not all water-based primers are created equally. There are several factors to consider when choosing the appropriate primer for your application.

When trying to manufacture structures with multiple layers, a chemical primer is usually needed to improve bonds between a substrate and a coating, such as an extrudate, or ink. Primers can also help to enhance barrier properties, aesthetics, and overall performance of the finished structure. Water-based primers are a common choice because they provide superior performance on a vast array of substrates and are generally a safer and more sustainable choice compared to solvent-based primers. However, not all water-based primers are created equally. There are several factors to consider when choosing the appropriate primer for your application.

- What process are you using?

Water-based primers are typically used in the manufacture of multilayer structures in one of two processes: extrusion lamination or extrusion coating. The way in which you are manufacturing your structure and the materials that are used in that process will be important factors in the primer selection process.

- What is the end-use application?

To determine the type of primer needed, you should consider the product’s end-use and the exposures that the product needs to withstand during its lifecycle. For example, if you are interested in creating a commercially compostable structure, it is important to ensure that all materials in the structure, including the primer, can offer all the requirements for performance and compostability at the end of its life. Also, if the end-use application is a package or container, something else to consider is what it is being designed to protect. For example, contents that are oily will need different containment properties than a package holding dry or dehydrated ingredients.

- What is the structure and where will the primer be used?

A wide variety of chemistries, processes, and raw materials are used to create primers. Knowing the target bond strengths and/or bond requirements, and the specific substrates and/or extrudates you need to adhere will be paramount in determining the correct type of primer for your application. Some primers can also offer barrier, surface modification, or other properties in addition to adhesion depending on where it will be used in the structure. Understanding the benefits and limitations of the materials you are working with will help you better understand the properties your primer needs to provide.

- What are the regulatory requirements needed for this application?

Will the primer have direct or indirect contact with food? Do all the materials in the structure need to be REACH registered, Halal certified, or free of Substances of Very High Concern and/or Prop 65 components. Be sure to verify that the primer you choose has all the regulatory requirements you need prior to finalizing your selection.

- What is the application method?

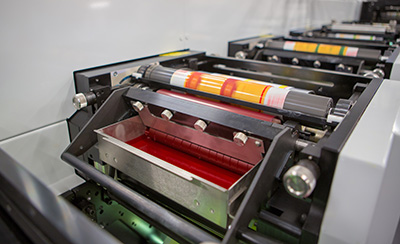

How will you apply the primer? Application methods may vary depending on the process and materials used. The primer recommendation may change depending on whether the application method is via smooth roll, gravure cylinder, Meyer rod, spray coating, or a flexographic printing press. Also, knowing whether the primer will be applied inline or offline may also play a part in your primer selection. For example, if you are applying primer offline on film, and the film is then rolled up and stored until it is ready to be used in the next step of the converting process, a non-blocking primer will be needed so that the primer does not transfer or adhere to the other side of the rolled substrate.

- Do you need any technical support?

There are many complexities that need to be addressed when working with water-based primers. Water-based primers usually require pre-treatment prior to application and need to be adequately dried to ensure optimal bond strength. Line speeds, time in the air gap, and dilution formulas as applicator rolls wear all need to be monitored and adjusted regularly, too. Understanding the level of technical support you need, and what your primer supplier can provide, is paramount to ensuring long-term success.