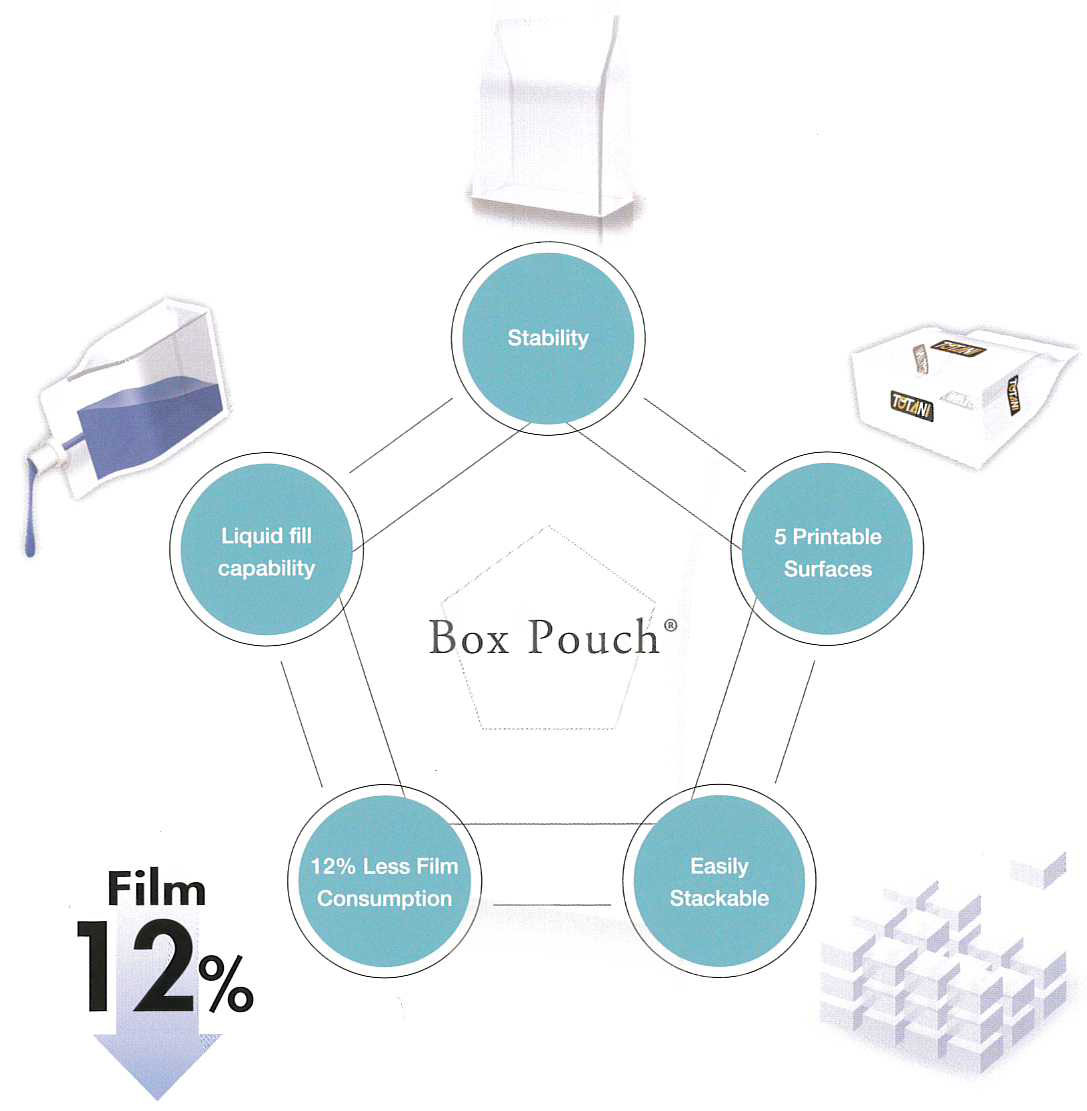

Box Pouch®

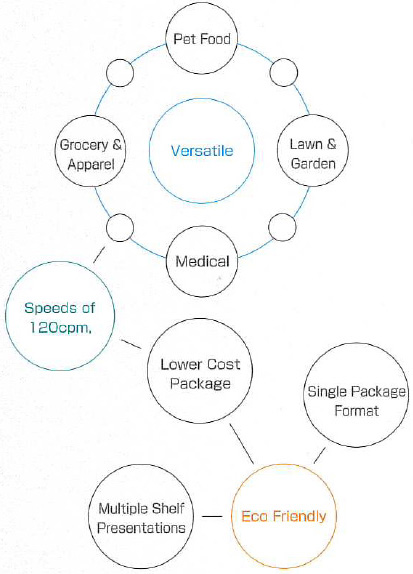

Totani’s original design is versatile (food, pet food, coffee, lawn and garden, etc.), has a great shelf presence (multiple shelf presentation options, 5 printable surfaces) and is eco-friendly. This package format is capable of reducing film content by 12% (when compared to a stand-up pouch of the same volume).

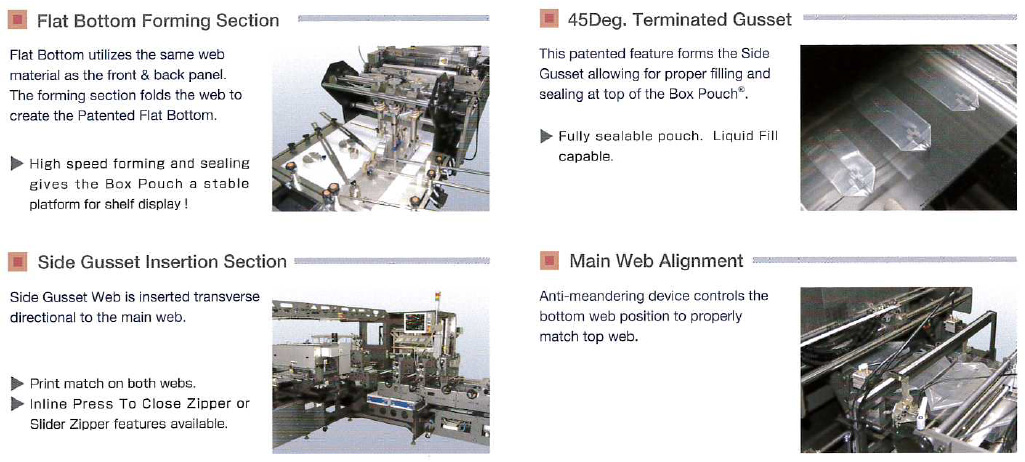

Features of the BH-60DG-F

Machine Improvements

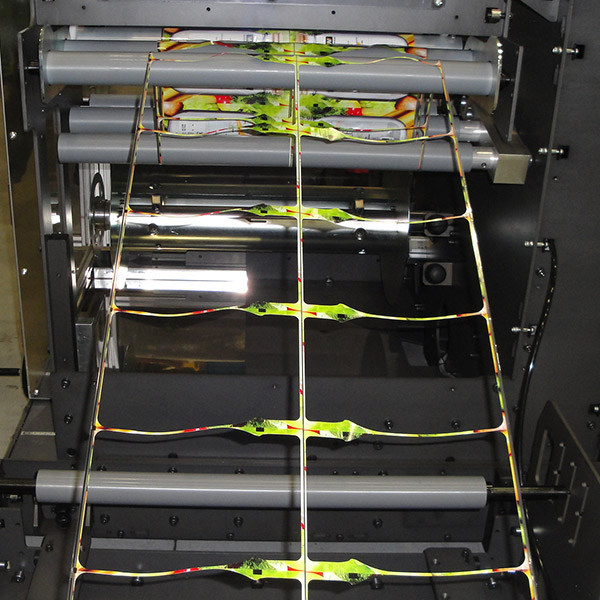

New “sustainable” films have unique material properties that need to be addressed during the pouch making process. There are a number of features that can be added to the pouch machine to better handle these films.

- Ultrasonic zipper crushing to lessen the amount of heat needed.

- Increase in the up/down stroke of the machine to lessen the effect of radiant heat.

- Automatic film direction blade adjustment to compensate for any film repeat variation.

- Special coated seal bars to prevent film from sticking.

- Seal prevention device used to stop the bottom gusset tacking together.

- Air curtain deployed at machine stop to reduce the effect of radiant heat.

All tension zones controlled by mark sensors to improve print registration and remove wear parts.

HQ “Green” Initiatives

There are a number of environmental initiatives that Totani has taken to reduce our environmental impact.

1

Installed solar panels to provide clean energy for the building.

2

Store and use rain and well water for the garden pond, sprinkler water and toilet use, all to conserve water resources.

3

The building itself has an open courtyard and terraces, the windows, walls and roof are highly insulated and all lights are controlled by motion sensors; all of which contribute to the conservation of energy.

4

The parking lot is surrounded by zelkova trees and other plantings and there is even grass planted between the interlocking blocks; all of which to absorb CO2 and control rainwater.

5

Paper (order forms, delivery slips, invoices, etc.) is discouraged and all processes are handled electronically. Everything used at Totani in the production of our machinery (oil, grease, plastic film waste from machine testing, etc.) that is possible to reuse or recycle is done so.

Automation and Quick-Change Features

By adding features for quicker changeovers and automating some of the set-up and adjustment processes we can not only lessen the time it takes to complete the changeover, but also decrease the amount of film consumed during set-up.

Cross section auto-positioning system allows for all units to be set automatically to a specific repeat or saved recipe. This feature also allows for the units to repositioned automatically in response to any repeat variation while the machine is running.

Quick release tooling lets the operator swap seal tooling in a matter of seconds instead of minutes.