Web Lines | Winding Process Fundamentals, Pt. 1

- Published: January 14, 2013, By Timothy J. Walker

Understanding winding, roll defects (e.g., tin-canning), and winding-related web quality (e.g., bagginess) begins with understanding how the web, winder design, and process conditions combine to create the stress and strains of the wound roll.

To understand the stresses and strains within a wound roll, we must understand four things:

- What determines the web tension as it makes first contact with the winding roll?

- How is the tension controlled from the first to final lap of the winding roll?

- How do dimensional changes within a roll (e.g., compression) change roll strains and stresses?

- How do transverse direction variations in equipment or web properties affect roll structure? Here is the first of a four-part series on winding fundamentals.

Here is the first of a four-part series on winding fundamentals.

PART 1: WINDING CONTROL: CREATING WOUND-ON TENSION (WOT)

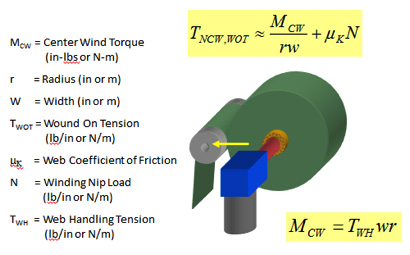

The tension of the web as it first makes contact with the winding roll (called the wound-on tension or WOT) is a strong function of two variables: center torque and surface nip load.

Understanding how applied center torque (in force x radius) becomes tension is easy. Torques are a force times a distance. Reversing this relationship, we can find the force of winding tension will be center torque divided by roll radius.

Understanding how surface nip load creates tension is less straightforward. Nipping the web as it enters the winding roll elongates the web much like a rolling pin on cookie dough. Just as cookie dough must slip on the baker’s sheet to stretch, so too must the web slip relative to the layer below it in the winding roll. This dependence on slippage makes the relationship of nip load to tension friction dependent. For low to moderate nip loads (<10PLI or <2000 N/m), a good estimate of tension created by nipping (a.k.a. nip-induced tension or NIT) is found by multiplying the nip load (in force/width) by the coefficient of friction of the product’s side A to side B. For a product with a coefficient of friction of 0.25, nipping with 4 PLI (700N/m) is like turning up the tension 1PLI (175 N/m).

The total wound-on tension is the sum of tension from center torque and nip-induced tension.

The above relationships of center torque and nip load apply to surface winders and combination center-surface winders with a couple additional considerations. For surface winders, there is no center torque, so that term is eliminated. Also, some surface winders may not be completely isolated from upstream web handling tension. Adhesion, mechanical entanglement, or gravity may change how the web slips on the surface drum, increasing the WOT above what nip load alone can account for.

Web handling expert Tim Walker, president of TJWalker+Assoc., has 25 years of experience in web processes, education, development, and production problem solving. Contact him at 651-686-5400; tjwalker@tjwa.com; www.webhandling.com.