Featured Stories

-

Tension: The First Thing We Must Get Right

Web tension is arguably the most important parameter for any web process. Tension is the first thing we must get right. -

Principles of Narrow Web Slitting

For those veterans in the slitting-winding community, this commentary is not necessarily new information, but reviews are always good too. -

Recyclability & Circularity Consumers Support Sustainable Brand Packaging

Sustainability has never been more central for the printing and packaging industries.

News | New Products

-

BioEmitter®- Keeping Corrosion and Rust at Bay in Enclosed Spaces

One of the most important missions of Cortec® Corporation, a global leader in the corrosion protection industry, is environmental responsibility.

-

Fedrigoni Names New Commercial Senior Vice President, Chief Marketing Officer

Fedrigoni — the world’s leading manufacturer of specialty papers, premium self-adhesive materials, RFID and connected solutions

-

SEI Laser Converting chooses Vetaphone for surface treatment

SEI Laser Converting is based in Buja in the northeast corner of Italy.

-

Former Division of the Knox Woolen Mill in Camden Acquired

Edward H. Best Company has been acquired by Windward Ventures LLC, a Maine-based investment group.

-

Miraclon and BOBST reinforce strategic partnership

Miraclon and BOBST have reinforced their strategic partnership, with Miraclon named as the plate technology partner in BOBST’s new Competence Center in Atlanta.

-

Anderson & Vreeland announces the expanded role of Tyler Thomas as National Sales Manager - U.S.

Anderson & Vreeland, a prominent manufacturer and distributor of flexographic print technologies, equipment, and consumables, is pleased to announce the expanded role of Tyler Thomas as National Sales Manager - U.S.

-

Valve Actuators with Longer Lifespan

QTRCO has innovated actuator designs specifically for high cycle, high speed, high reliability applications

Expert Advice

New Adhesive Achieves Cure, Regulatory Compliance in 3 Days

- Published: June 09, 2009

Converters struggle with rising costs and an increasing awareness for food safety. Of all available lamination technologies, solventless polyurethane (PU) adhesives are the most cost-effective.

With adhesive coat weights typically ranging from 1–1.15 lb/ream, these adhesives offer good adhesion to a wide variety of substrates. Printed, metalized, or otherwise coated materials and a myriad of sealant layers are no problem. These systems are convenient to use with near-room-temperature application and long potlives.

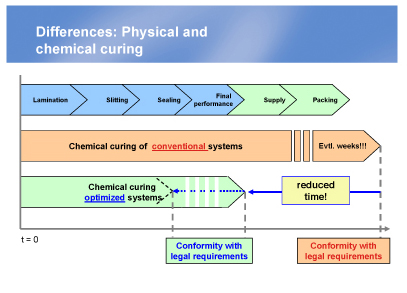

Conventional solventless systems, however, require long storage times in order to comply with food safety regulations. With unique curing technology offered in a new line of solventless PU adhesives, bond development and food safety compliance are both achieved in a very short time.

Compliance testing performed using 3% acetic acid is the most stringent, worst case scenario to meet the FDA regulations. These new technology adhesives meet the dual needs of physical performance and regulatory compliance for food safety in less than three days for the majority of structures, compared to the many weeks required by conventional systems.

A recent study compared the relationship across a range of variables including substrates, coating weight, cure conditions, moisture, etc. Special attention was paid to the filling good used as the food simulant in the migration test. In a time of increased environmental awareness and food safety, these new adhesives offer fast cure without compromising food safety.

Rapid Compliance

A laminate manufactured with the ideal adhesive would be in compliance with food safety legislation at the same time it reaches its full physical performance. Flexible packaging suppliers must allow a certain storage time for the PU adhesive to cure prior to further processing, e.g., slitting, pouchmaking, etc. It is the obligation of the flexible packaging manufacturer to ensure that the packaging material introduced into the market complies with all relevant food safety regulations.

With conventional two-component room-temperature adhesive systems, the storage time eventually can take weeks. Due to a special curing mechanism, new laminating adhesives cure fully and reach legal compliance in only a few days.

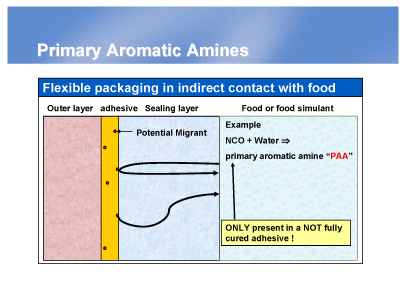

Migration of Primary Aromatic Amines

If the laminating adhesive is not fully cured and still contains unreacted monomeric diisocyanates, these substances may migrate through the sealant film and into the food.

Once migrated, they will react with most ubiquitous moisture and form the corresponding primary aromatic amines. Primary aromatic amines have been classified as carcinogenic.

Page 2 of 4

Analytics of Primary Aromatic Amines

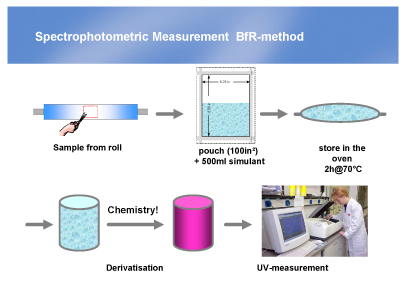

The most practical approach to test a laminate for migratory amines is to make pouches, fill the pouches with a suitable food simulant, then seal and store them for a defined time at an elevated temperature. After storage, the amount of migratory amines in the food simulant will be measured.

There are many methods available to measure the amount of primary aromatic amines present in test solutions.

In one method—the so-called photometric test—the amines are derivatized with a coupling agent to form a colored dye. The intensity of the test solution is proportional to the concentration of primary aromatic amines (following Beer’s law) and can be quantified with a UV/VIS spectrophotometer. The detection limit for this method, which totals all primary aromatic amines, is 2 ppb.

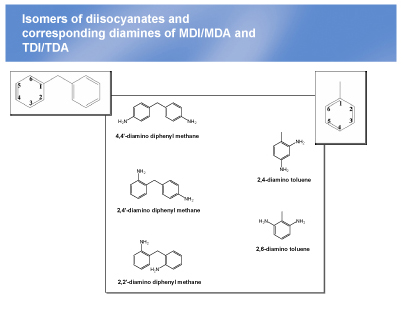

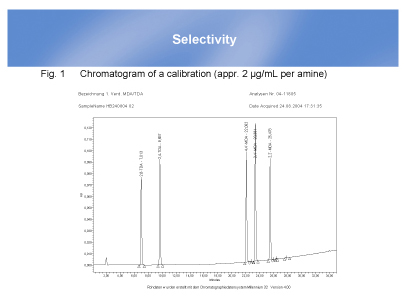

Another method uses HPLC/UV coupling to measure the amines directly. Via high pressure liquid chromatography, the isomers of the primary aromatic amines are separated from each other. Therefore this method is sometimes called the “specific migration method.”

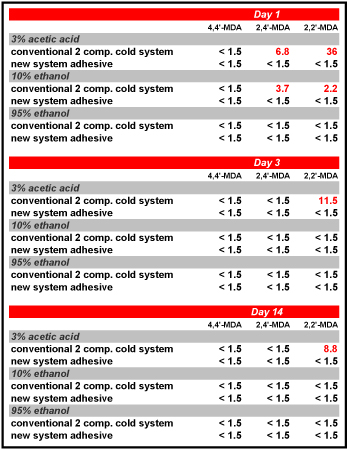

The retention time along with the UV spectrum of the isomers is used to identify the extracted substance. The detection limit for this method is 1.5 ppb per each isomer.

Both the photometric test and the specific migration method focus on determining the amount of migratory amines only. The GC/MS method separates all substances by GC and analyses the separated substances by mass spectrometry.

The advantage of this method is that it also finds substances other than primary aromatic amines. The major disadvantage of this method, however, is the very high injection temperature, which can induce GC specific chemistry during the measurement.

Comparative Study of Conventional Systems and New Technology Adhesives

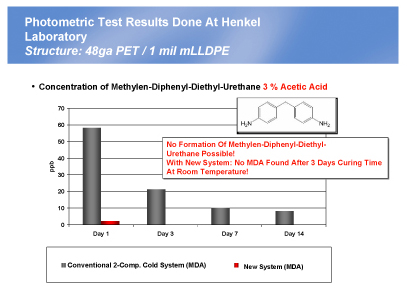

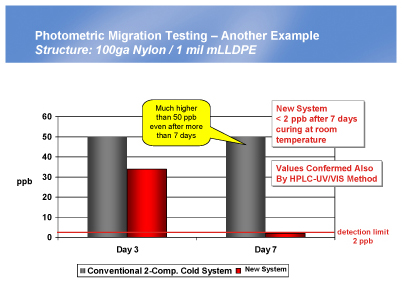

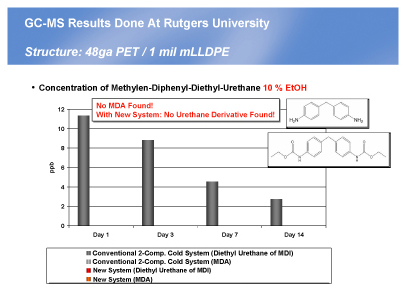

A 48-ga PET/1 mil mLLDPE and a 60-ga Nylon/1 mil mLLDPE laminate have been manufactured with a conventional curing system and the new technology system. The laminated samples were shipped overnight to Rutgers Univ. Pouches were made from them after 1 day, 3 days, 7 days, and 14 days’ cure time. The pouches were filled with different food simulants.

Page 3 of 4

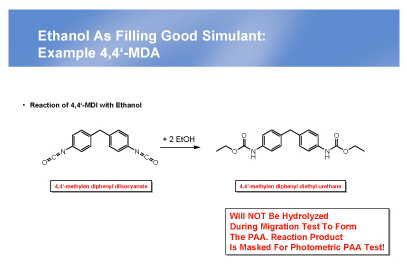

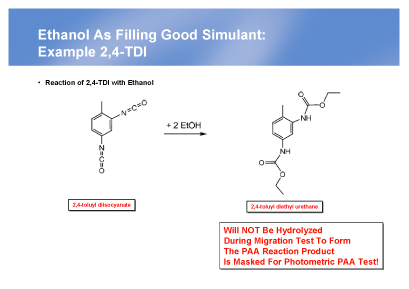

The sample solutions have been analyzed by GC/MS. The most interesting result from this study was that in case of 10% ethanol as the food simulant, no MDA was detected even in the case of the conventional curing systems. Instead the reaction product of MDI with ethanol was analyzed.

As expected, ethanol is the preferred reaction partner rather than water for MDI. The diethyl urethane derivative, however, is stable and will not be hydrolyzed under the storage conditions of the sample preparation.

This means that through the reaction with ethanol, diisocyanates are partly masked and cannot be converted to the corresponding primary aromatic amine.

So far, we have not been able to calibrate the photometric test for the measurement of ethanol solutions. The much more severe test with 3% acetic acid clearly demonstrates that conventional systems cannot be considered safe for food packaging applications. Even after 14 days, primary aromatic amines are detected.