Directing Design

- Published: February 01, 2007, By By Mark Vanover Esko-Graphics

Process Workflow

When I meet with large consumer products companies (CPC), I’m often told there can be as many as 20 individuals involved internally in the packaging workflow, each of whom has to give some kind of approval before the package can be manufactured.

Confronted with globalization, outsourcing, and increasing pressure from mega-retailers, brand marketers are charged with seemingly irreconcilable directives from upper management: lower costs, accelerate time-to-market, drive quality, ensure regulatory compliance, and build brand equity.

Because design has become the No. 1 differentiator for product innovation among manufacturers, design life-cycle management (DLM) has gained prominence as a packaging system tailored to meet the needs of CPCs and their graphic communication partners. Integrated and web-based, DLM streamlines the package design and production process—from ideation through design, packaging, and production.

DLM enables a company’s employees and its outside vendors and design partners to communicate, collaborate, and execute decisions upstream, downstream, and everywhere in-between. In fact, a multi-lingual communication and collaboration system now has become essential in today’s global economy. Companies can produce significant savings in cost and time.

Hotwire Supply Chain Communications

Many people believe an asset management system and workflow embedded with powerful communication technology is all that’s needed. That’s only half true. Providing the tools to collaborate on a design while it’s in process is the other half. The reward: faster turnarounds, more efficient workflows, and ultimately, loyalty.

So what are some of the tools that can make a big difference?

- Think in 3D, design in 3D: Package designers usually think in three dimensions but often must draw a structural design on a two-dimensional “drawing board.” With the right software, designers can create packaging designs in 3D, fitting a design—even internal supporting fittings and windows that follow the product’s shape—from a 3D CAD product model. Users can resize a single file to create a wide variety of shapes and sizes.

Complete 3D integration allows quick prototyping of designs, eliminating communication errors and reducing design review cycles. Users can create completely animated presentations demonstrating products, their packaging, and the assembly of all parts of practically any packaging project—with 3D parts and renderings of packaging from many angles. Several design iterations can be presented to the CPC and then fine-tuned before production samples.

- Get smart: What is the cost on press of the wrong bar code or incorrect legal or ingredient copy? Linking graphic design elements with CPC information, directly from the source, drives the risk for human error out of the process.

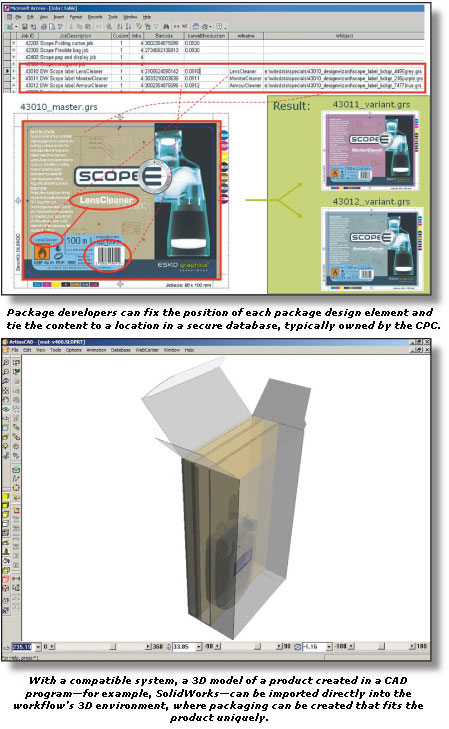

Available workflow modules let package developers fix the position of each package design element and tie the content to a location in a secure database—typically owned by the CPC. The modules provide the graphic designer with a quick, easy, and nearly flawless way to position this information automatically within the graphic design placeholder. Content can include logos, product variations, legal notifications, safety warnings, and bar codes.

The workflow advantages are quite evident. Data is entered only once, by a qualified individual with secure access to the databases, eliminating the errors and overhead associated with double entries or re-keying of data. And because the design is created when needed, there are no out-of-date instructions. Information is polled in real time, every time package design artwork is developed.

- Control versions: It is extremely helpful to keep track automatically of when a document has changed, who changed it, and why. Good packaging workflow systems provide viewable histories of a document in which users can compare previous versions of a document to see exactly what changed. Comparison tools also ensure that only the changes that were requested were made while keeping the other approved content intact.

“Check Out” and “Check In” features allow users to make changes to documents. Typically, only one user at a time can check out a document, but other users still can view the current version with the knowledge that another user is editing the document. This version control keeps two users from making changes at the same time, which can lead to one set of changes being lost.

- Coordinate with product design: If a product is created in a CAD program, why not use that CAD data as the basis for packaging design? For example, many package designers use SolidWorks, a widely used 3D CAD tool for product and primary packaging development as well as primary packaging elements like bottles and cans. Implementing a direct communication link between these products is extremely valuable.

With a compatible system, a SolidWorks 3D model can be imported directly into the workflow’s 3D environment, where packaging is created that uniquely fits the product. Operating directly with the 3D model not only speeds up the packaging development process dramatically; it also removes much of the manual trial-and-error process to get packaging to fit correctly.

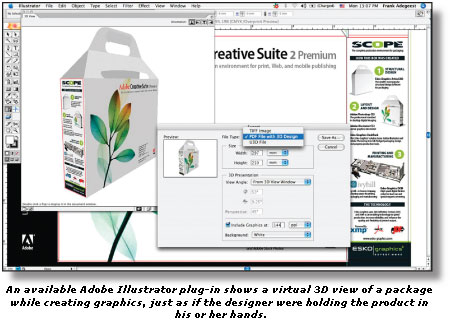

- Empower the designer: Why not provide the CPC designer with desktop prepress tools and get a head start on the workflow? Plug-ins put packaging and prepress technologies inside Adobe Illustrator, the most popular packaging graphic design application, turning it into a full-fledged production tool. With the ability to create step-and-repeat patterns, apply screening, preflight files, create dynamic bar codes, open structural design files, or apply consistent trapping, the designer is given a head start in the production workflow.

We discussed earlier that 3D visualization is a major advantage for design efficiency. An available Adobe Illustrator plug-in shows a virtual 3D view of a package while creating graphics, just as if the designer were holding the product in his or her hands. The results are 3D presentation material and 2D artwork that can be used for collaboration and approval and the pre-production part of the packaging supply chain, leading to a significant reduction of prototyping and proofing costs and time.

- Play well with others: You also can integrate a workflow with third-party software. For starters, imagine tying your CAD solution with palletization software to help make decisions about how the product is packaged. The more cartons in the container, the more containers on the pallet, the more product can be loaded on the truck. Many logistics decisions are made very early in the packaging supply chain. A small change in structural design for palletization can result in huge cost savings for the CPC.

Basic communication, collaboration, and web-centric workflows are only the start of an effective system for converters. In order to completely engage the CPC in an effective DLM system, there are additional tools that make a workflow complete and more efficient. I’ve listed a few instrumental ones here. There are more. When you look for a system, do your homework, and don’t overlook any of the pieces.

SUPPLIER INFO:

Esko-Graphics—PFFC-ASAP 305. esko.com

Mark Vanover is director of marketing for Esko, based in Vandalia, OH. His career spans more than 25 years with product marketing, branding, and sales roles for notable graphic arts companies. Mark is a frequent contributor to industry publications and an accomplished speaker at numerous packaging and print marketing forums. He can be reached at This email address is being protected from spambots. You need JavaScript enabled to view it..

The views and opinions expressed in Technical Reports are those of the author(s), not those of the editors of PFFC. Please address comments to author(s).