Appleton Mfg. Div. Delivers Unique Core Cutter

- Published: January 16, 2014

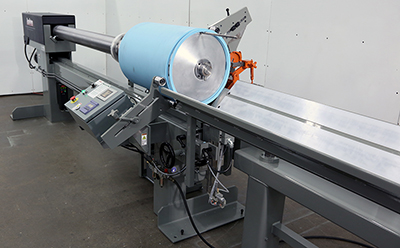

NEENAH, WI | Appleton Mfg. Division recently shipped an enhanced A400 Hydraulically Powered Core Cutter capable of cutting multiple materials and diameters. The customer, who wishes to remain anonymous, provided the Engineering and Design Team at Appleton Mfg. Division with a specific set of unusual criteria, the ability to cut a special plastic material with core IDs greater than 16 in. and very heavy wall thickness. The team was able to translate that criteria into the modified A400P-HD Hydraulic Core Cutter and deliver it to the customer in Q4 of 2013.

The A400P-HD Core Cutter can be configured so that with a simple tooling change, the machine can alternate between cutting parent cores of different material. The most common dual cutting configuration involves cutting fiber or plastic cores and that is the configuration used for this A400P-HD. The unique aspect of this application was the plastic material the client needed to cut. While the exact nature of the material cannot be revealed, the cost to produce was approximately $40 per in. For this reason, precision and consistency were vital requirements.

“Q3 and Q4 saw quite a few Special Projects for our Engineering and Design Team,” says Mark Rasper, who heads up the team as engineering manager. “The modified A400 Hydraulic Core Cutter was one of the more unique projects because of the materials involved. We delivered a machine that matched the customer’s needs and is performing to specification.”