On Print | Digital Printing: New Year Resolution

- Published: January 20, 2014, By Dr. Dene Taylor

Resolution for digital devices is a source of confusion. Printing expert Dene Taylor offers advice and resources

I’m always on the lookout for tools to improve productivity and performance in manufacturing. These come in many forms for the same subject—some simple and task-based, while others are sophisticated and project-based. Digital print resolution has a range. The basis is output from a carefully prepared file. Complexity depends upon the elements within the image. The simple files that we use when teaching new operators about inkjet are explained first.

The primary driver for tight resolution control in inkjet that I see is text and bar coding on labels and packaging. Clear text is a regulatory requirement for most retail and pharmacy items, but eye-catching graphics are far more valuable. There will always be pressure to maximize readability in the minimum area. Similarly, 2D bar codes have much tighter tolerances than the traditional UPC codes. There will be a continual drive to higher resolution. Monitoring tools should be in every printer’s digital tool kit.

What is Resolution?

Traditionally, resolution implied output measured from prints, and input was screen size. It is defined as the frequency of separate lines that are printed and that also can be resolved. Units are lines-per-millimeter or lines-per-inch (lpi). Directionality matters, so we look for machine and cross-machine values. Output, of course, is system dependent—media and ink are at least as important as the machine.

Resolution for digital devices is a source of confusion. By itself, resolution often refers to a machine parameter—the spacing of individual dots on the substrate. Hence, the units are dots/inch (dpi) or dots/cm. Native resolution, or maximum addressability, means the highest number of individually addressed dots that can be placed in a row cross web or in a lane down web.

Addressing every nib or nozzle individually drives up file size and processing time substantially. Hence, sets of nibs and nozzles are grouped in the RIP for efficiency and speed. This is the RIP resolution. Thus a device with 1200 x 1200 dpi native also may offer 600 x 600, 300 x 300, and 200 x 200 as options. Selecting appropriate resolution prior to the RIP is the first step in producing crisp images. It may also establish the resolution for any vector content, such as embedded text, and that might be problematic. In another twist, some devices just do not print native resolution.

Again, native resolution is the frequency of dots that can be placed; it is not dot size. It is tempting to think that, as technology has evolved and machine resolutions have gone from 200 to 300, 600, 1200, and even 2400 dpi, we can automatically expect better print resolution. Additionally, dots are now often generated with grey scale, which should improve resolution, especially edge acuity, just as it does for offset, gravure, and flexography. But that is not automatic. Droplet trajectories are not all straight, and ink spreads on the substrate. Thus, output needs to be measured or at least compared to standard.

Measuring Print Resolution

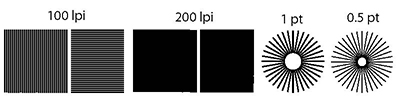

Measuring print resolution starts with files in which there are groups of lines with differing spacings. The wheel spoke has linearly increasing separation as the spokes diverge from the hub. Our version (Figure 1) was prepared in Adobe Illustrator. The line widths are set (½ and 1 pt). Additionally, we make the hub, which is where the spokes in the image file meet, white. If the spokes are long and the black circle around the hub is small, resolution is high. A large hub means resolution is poor. This graphic works well when run routinely and samples are retained as standards for visual comparison. Actual resolution can be calculated—This email address is being protected from spambots. You need JavaScript enabled to view it. to learn how.

An easy way to obtain a number is to print groups of lines with different separations, e.g., standard offset screening. Print resolution is the smallest spacing where the lines are distinctly separate. In Figure 1, the black bars and the spaces between them have identical width in the file—1/100th or 1/200th in. for left and right pairs respectively. If the left set’s bars are distinct, but the right’s are not, print resolution is between 100 and 200 lpi. Expanding or reducing copies of the set quickly produces graphics for desired resolutions. We strongly recommend running the primaries separately—colors get compounded by registration.

Customers are usually more interested in text clarity than in process control measurement. Our basic file has both positive and negative text in a range of sizes (Figure 2). We change the text to match client or job. Black usually gets the most attention, but it is good practice to print all primaries. Sometimes we see that magenta or cyan is added to increase black text contrast, but that almost invariably degrades the sharpness because of alignment issues.

The Resometer

For those who are skilled digital printers looking for premium output, these files will prove inadequate. You need something more. For example, in September 2013 at the PFFC/CPP sponsored conference series, Henry Freedman of Technology Watch spoke on measuring the many attributes of print quality. One of the tools he described is the Resometer, a vector file that includes multiple features to assess and control resolution of the separate primary colors.

The Resometer print includes not only positive and negative type as the wheel spoke image for angular dot gain, but also line groups, vector versus bitmap comparisons, and a bitmap photographic image. Font resolution is assessed visually, and recorded as the size at which text is readable and free of artifacts or defects of concern in the application. It may vary with font, and as differences in font size are proportionally large, it is less discerning than resolution from lines. It is well known that resolution of inkjet is dependent upon image density (dot gain), but less well understood that it depends also upon contrast. Resometer shows both.

Obviously this file also can be used to track machine performance and to make comparisons across devices, especially when a product is qualified on one machine, and it needs to be made elsewhere—again, a procedure where performance can be judged and enumerated, and not just based upon a visual appearance. And because it based on simplicity, responses from deliberate of unintended changes in the process or the substrate are immediately obvious. Process control requires documenting the press variables, typically by recording in a file or in the press journal. Resometer adds device and RIP information to the print.

Other sources for files are print quality services and consultants. If you have someone familiar with your system, contact them first. And if you have better files you want shared, we can do that through this medium.

Printing expert Dene Taylor, PhD, founded Specialty Papers & Films Inc. (SPF-Inc.), New Hope, PA, in 2000 for clients seeking consultation for technical management, new product design, development, commercialization, and distribution, as well as locating/managing outsourced manufacturing. Contact him at 215-862-9434; This email address is being protected from spambots. You need JavaScript enabled to view it.; www.spf-inc.com.