Esko Updates Design Software

- Published: October 26, 2015

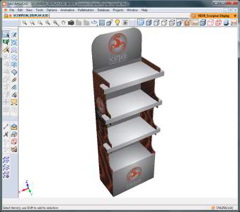

GHENT, BELGIUM | Esko announces the rollout of its newest release of ArtiosCAD, structural design software for packaging design. The updated version showcases Canvas Design which, thanks to a series of new features, is said to improves the workflow for anyone designing and producing multi-component displays and packaging.

"Displays are becoming ever more complex, with more and more pieces and parts,” says Richard Deroo, Esko product manager, Structural Design. “Designers like to create all parts on a single 'document' so they can see how each piece will interact and fit with each other. Imagine if you have a fifty-piece display built with several different substrates or materials. Designing them individually presents a true challenge trying to keep track of all the pieces. These enhancements make multi-part designing easier than ever before."

The new Canvas File in ArtiosCAD is a master design template. A designer can create all the pieces on a single canvas and see how they interact. From that one canvas, user can now redirect those components that need graphics, separate the components based upon how they are manufactured, and identify each part for reports, database searching, or for integrating with a business system.

Company says ArtiosCAD maintains a unique board assignment for each part. Parts made on mixed substrates can be designed and viewed together. Unique database information is stored for each part, making them easy to identify. When parts are output, they can be done so, separately. Moreover, if a separate part file is edited, ArtiosCAD notes the change and allows it to be updated on the master Canvas File.

Reportedly, there are many areas in which ArtiosCAD streamlines a workflow. For example, it makes it easy to tie into an MIS, allowing the business system to create unique parts for inventory and costing; or helping to run a bill of materials. If a display is created, only those parts that require artwork can be sent to the graphic design department—not the entire display, eliminating any possible confusion.

For manufacturing, companies are now able to separate the canvas into different parts and deliver only those pieces that require a specific manufacturing technique, e.g., to a die maker or to a Kongsberg table. It’s even possible to add non-design elements such as a pallet for transport or assembly hardware to the workflow, which are then referred to as non-production parts.

The upgrade is free of charge for ArtiosCAD customers worldwide with maintenance contracts.