Shurtape Addresses Product Damage Due to Knives

- Published: January 22, 2014

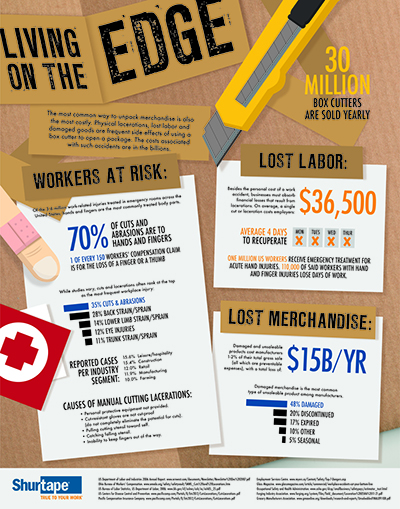

HICKORY, NC | Pressure-sensitive tape producer Shurtape is addressing the preventable costs associated with using a knife to open a package. The company reports that, every year, damaged products costs manufacturers 1%–2% of their total gross sales. That’s an estimated $15 billion per year spent on preventable expenses. Not to mention the significant costs businesses absorb related to injuries from accidents involving knives.

To address the often overlooked issue of damage—and injury—due to sharp instruments, Shurtape has recently introduced the ShurSEAL Solution, which combines its HP Series packaging tape with a PrimeLoc tape applicator. This box sealing solution offers unique features, such as unmatched wipe-down force for more secure seals and an exclusive folded-edge technology, which creates an easy-to-open seal that doesn’t require a knife.

The HP Series hot melt carton sealing tapes are said to have the highest holding power in the industry and perform reliably down to the core. The tape applications (models SP 7000 and SP 6000) are optimized for high-speed automated case sealing and are easily retrofitted to all leading brands of case erecting and case sealing equipment. According to the company, features include:

- Unmatched wipe-down force: multiple flexible wipe-down points allow for full utilization of the tape's adhesive to form a secure seal, even on under-filled cartons. This also provides increased fiber tear when the tape is removed, offering tamper-evident security.

- Edge folding option: exclusive folded-edge technology creates a secure, easy-to-open seal that doesn't require a knife. The folded edge runs the entire length of the carton as the tape is applied. The double-thick edges increase the thickness of the tape at its most vulnerable failure point—where the tape folds over the edge of the carton. The folded-edge feature is especially handy for retail packaged products and high-value merchandise where you don't want to damage package contents when opening the carton with a sharp blade.

- High speed: the SP 7000 runs at line speeds to 160 fpm while the SP 6000 runs to 120 fpm.

- Other features include a dual-axis locking mandrel, front and rear tab length adjustment, and a self-cleaning safety blade.

The tape applicators are built tough to resist corrosion and are easy to load. The SP 7000 is constructed with 100% stainless steel/anodized aluminum for wash-down applications; the SP 6000 features a corrosion-resistent mild steel construction for long-term use in most environments.