Premier™ Slot Die from Nordson Can Get ROI in Months

- Published: November 07, 2018, By Christine Pietryla Wetzler

The tool, called the Fluid Coating Payback Calculator, can be accessed online at http://www.nordson.com/en/divisions/polymer-processing-systems/support/calculators

Using these inputs, the tool automatically calculates the cost savings achievable with slot die coating for substrate material, coating fluid, and labor. The total of these savings is compared with the one-time costs of investment and engineering to yield the payback time for these costs.

“While the cost of investment in a slot die system can be significantly greater than for most roll-coating systems, the savings yielded by slot die coating often make it possible to pay off the initial investment in a matter of months,” said Patrick Meinen, business development manager for Nordson’s fluid coating systems. “Of particular value is the unique capability of fixed-lip slot dies to apply more than one coating in a single pass, making possible a complete coating line.”

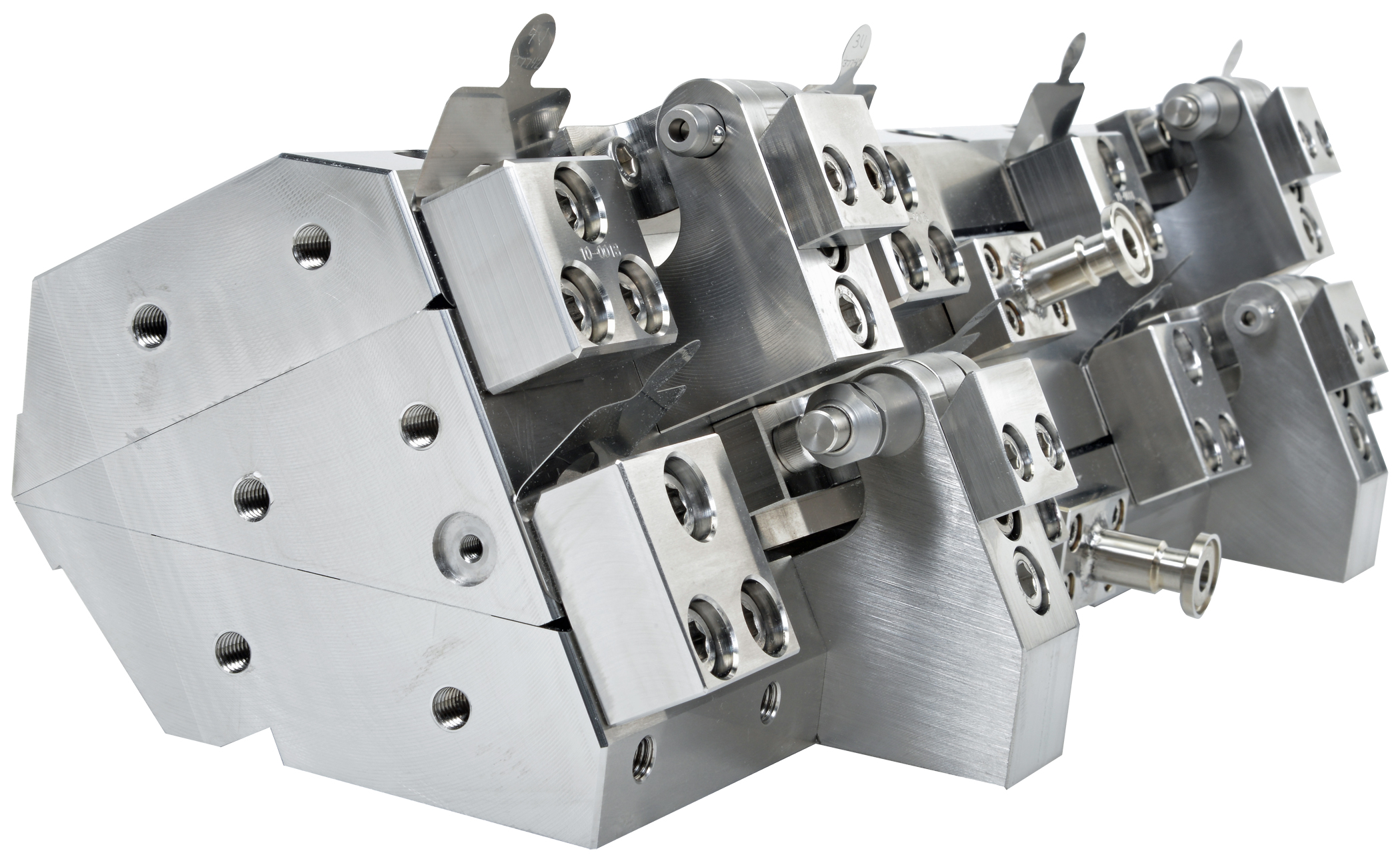

A Premier™ slot die supplied by Nordson can be engineered to apply two or three coatings simultaneously yet can also be used to apply single layers.

This email address is being protected from spambots. You need JavaScript enabled to view it.