A Look at Liquid

- Published: February 01, 2007, By By Corey M. Reardon AWA Alexander Watson Assoc.

To view the entire report as a PDF, click the link below:

Part 1 | Part 2 | Part 3 | Contract Servicing Directory | New Products

A Look at Liquid

The extrusion coating market is mature in North America, growing overall, across all market segments, at about 1.5%–2%/yr. Flexible packaging accounts for most of this growth, but liquid packaging still contributes 2%/yr growth and remains of interest both to extrusion coating companies and their suppliers.

In North America, 81% of liquid packaging production is in the "old technology" gable-top cartons, with the remaining 19% in aseptic cartons.

Gable-Top Liquid Packaging

Typically made from one layer of polyethylene (PE)-coated bleached kraft board, the gable-top carton originally was developed for milk, which continues to be a major application—with 20% of the market—in the smaller serving sizes (half pint, pint, and quart). Plastic containers now dominate for larger sizes, as in other liquid packaging segments, and according to US Dept. of Agriculture statistics, account for 80% of fluid milk sales. The substitution of gable-top cartons by plastic has been offset to some extent by new applications in packaging for juice, other foods, and nonfood packaging for dry materials such as powders. Together these new applications represent an estimated 25% of the current gable-top liquid packaging market.

Product Innovation

Gable-top products have evolved to include many innovations such as windows, pour spouts, and creative shapes, offering market appeal for both dairy and juice applications.

Innovations in improved multi-ply barrier cartons are expected to widen the opportunities for this package construction. Coextruded barrier materials have been developed and commercialized for containers and foil liners that improve quality and freshness and/or extend shelf life.

Gable-Tops: Market Outlook

The market outlook for growth in paperboard liquid packaging is 1%/yr. This small overall growth is driven by good growth in fresh juice, juice and tea drinks, other food, and nonfood products.

Milk packaging is expected to be flat in the coming years. Competitive pressure in the smaller-size milk serving containers is emerging, again, in the form of plastic bottles. These have proved attractive to fast food chains such as McDonalds and Wendy's, which adopted this packaging in 2004.

In addition, overall milk sales have been dropping in recent years by as much as 3%–4%/yr as a result of a marketplace surge in alternative beverages and dietary concerns.

Aseptic Packaging

Aseptic packaging constructions typically involve a multi-layer PE/paperboard/PE/foil/PE laminate. The construction is generally 70% paperboard, 24% PE, and 6% aluminum by weight.

Aseptic packaging was developed in Europe by Tetra Pak in the early 1960s, and this multi-ply packaging system has been expanding rapidly in North America since its introduction for juice box applications in the early 1980s.

The total market for aseptic packaging in 2005 is estimated at 286,000 tons. Of this total, 143,000 tons were produced in North America and another 143,000 tons were imported.

Features & Benefits

In North America, aseptic containers are used to package juices, soy products, wine, syrups, and some other food products. These aseptic packages are shelf-stable: They do not require refrigeration in order to retain product freshness. This is accomplished by sterilizing the paperboard and filling the cartons in an extremely clean environment. This is their primary advantage.

In addition, they are lightweight and strong, pack well for shipping, and are convenient for the consumer to carry and store.

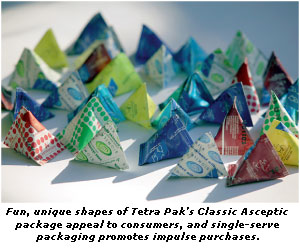

Market growth for aseptic packaging is estimated at more than 3%/yr, fueled in North America by away-from-home eating habits (50% of food consumption takes place out of the home). The package requirements are therefore convenience, esthetics, and a high degree of product protection—requirements that aseptic packaging meets for an increasing portfolio of products. Package design continues to evolve: Innovations include the provision of "windows" so the liquid product is visible, microwavability, improved graphic quality, and improved openings (spouts, straws, etc.).

Environmental Issues

Environmental concerns about aseptic packaging led to a reduction in overall package weight coupled with an increase in the renewable resource component—the paperboard—as a percentage of total package weight. On the other hand, aseptic packaging is said to be more energy-efficient in processing and far more energy-efficient in storage, eliminating the refrigeration requirement until opened and reducing volume requirements and weight during transportation.

Market Share

European usage of aseptic construction is more widespread than in North America, undoubtedly related to the energy and space-saving benefits. Overall, European liquid packaging market share for aseptic packaging is 75%, with North American liquid packaging use currently in inverse ratio. Gable-top cartons take approximately 63% of total consumption and 19% share of domestic production.

Corey M. Reardon is president and CEO of AWA Alexander Watson Assoc., Amsterdam, Netherlands, a market research film specializing in packaging and converting. Shortly the company will publish "Extrusion Coated Materials—North American Market Study 2007—Market Overview and Trends for Extrusion Coating Companies and their Suppliers." Contact Reardon at +31 (20) 676 20 60; awa-bv.com.

Part 1 | Part 2 | Part 3 | Contract Servicing Directory | New Products