Verstraete IML Helps Hershey’s Succeed in Brazil

- Published: January 21, 2016

VLIEGPLEIN, BELGIUM | Verstraete IML reports that Hershey’s recently introduced its popular Chocotubs—crunchy cookies with a chocolate dip—into the Brazilian market using IML packaging with labels from Verstraete instead of adhesive labels. According to Verstraete, IML is lighter, more sustainable, and looks better.

Ana Fontes, Hershey’s R&D manager in Brazil, says, “In the second quarter this year, we introduced Hershey's Chocotubs on the Brazilian market. The package had to be an eye-catcher on Brazilian store shelves while creating real added value. We wanted to bring innovation to the growing on-the-go market. That’s why, after many months of research, we chose IML packaging.”

Injection molder Plast & Pack joined forces with Verstraete IML and Hershey’s Brazil. Ricardo Bruni, general manager at Plast & Pack, says, “We know we can rely on Verstraete IML for top-quality IML labels. Verstraete IML has 25 years’ experience in printing IML labels. Thanks to their know-how, we were able to make a success of this technically complex project for Hershey's Brazil. Since our first cooperation, I have been recommending Verstraete IML as a commercial and technical IML partner. We have already introduced Verstraete IML to the local and regional industry, for example, to Abiplast. But in addition, we recommend Verstraete IML as a worldwide partner for IML labels and IML know-how.”

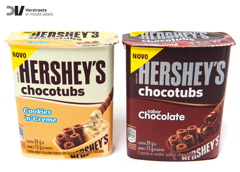

Hershey’s Chocotubs are available in 52-g IML packaging, in two flavors: Milk Chocolate and Cookies’n’Creme.

This year ABRE, the Brazilian packaging association, honored Hershey’s Chocotubs as the winner in the “Sweets and desserts packaging” category. It was the first IML packaging ever to compete in this category. The panel reportedly was won over by this modern packaging and was impressed by the advantages of IML packaging. And it’s 100% recyclable, because with IML the label is integrated into the packaging itself. Label and packaging form a single entity, which simplifies the recycling process later on.

Says Fontes, “Choosing IML technology resulted in reduced investment costs by Hershey’s Brazil. Thanks to the in-mold labeling process, the production and labeling of the packaging take place in one operation. The costs of post-production labeling and the associated storage and transport costs fall away with the new production line. The offset printing technique provides IML labels with high-resolution images in up to eight colors. This superior quality is crucial, because high quality photographic images attract the consumer—the new product grabs more attention at the sales outlet—and they highlight the excellent quality of the product. Plus, with one IML label, we decorate all sides of the packaging.”

This email address is being protected from spambots. You need JavaScript enabled to view it.