Packaging for the World

- Published: September 30, 2004, By Stanley Sacharow, Contributing Editor

With multinational clients and global suppliers, South American converter Alusa produces... Packaging for the World.

Superbly situated in Santiago (pop. 5 million), Chile's biggest city, Alusa SA is the largest flexible packaging converter of the south cone (Chile and Argentina) and among the top six in Latin America. Supplying a veritable “who's who” of food multinationals, the company is headquartered in an award-winning facility near Santiago's bustling Arturo Merino Benitez airport. The complex also houses its main converting plant.

Alusa (US $65 million) belongs to the Luksic industrial group, one of Chile's most important financial organizations. This group controls more than $1.5 billion, giving the company the necessary support for its global projection in the world of packaging.

Like several other large South American flex-pack converters, Alusa's origins go back to the rotogravure business. This company began operations in 1961 as a small gravure printer founded by the Zecchetto family — newly arrived from Verona, Italy. In 1992 Alusa acquired the main local flexographic printer, Vigaflex SA, and in 1993 began its international expansion with the greenfield construction of a flex-pack plant in San Luis, Argentina.

Looking northward for expansion, in 1995 the company acquired 25% of the leading flex-pack converter in Perú — Peruplast and its sister operation Tech Pak — and in 1997 opened sales facilities in São Paulo, Brazil. Marcelo Valdiva, Alusa's genial general manager, told PFFC during an exclusive visit that “we would like to expand our export market to at least 20 percent of our production. We especially look to new markets and invest heavily in the latest equipment.”

Global Suppliers

There are two production facilities in Santiago. The main plant is 14,000 sq m with 350 employees on three shifts. The second plant is a much smaller one with 90 employees. A third plant, located in San Luis, Argentina, has 170 employees and 7,000 sq m.

Both the cleanliness of the facility and the many examples of world-class equipment used in the production process were evident during a tour of the main plant with Alusa's marketing director, Tristan Molina. Molina explained, “We have many multinational clients such as Nestlé, and very often they visit our plants. In fact, personnel from Nestlé's headquarters in Switzerland fully qualified us as a global supplier.”

There are six rotogravure presses — two Rotomec (eight- and nine-color) and four Cerutti (one six-color, two eight-color, and one nine-color). Electromechanical engraving of cylinders is both extensive and efficient. There are four Ohio Electronic Engravers (now manufactured by Max Daetwyler Corp.). This unit contains four presses, one Uteco, two Comexi, and one Bielloni. Supporting this is a fully equipped prepress operation using computer-to-plate technology.

There are also four blown film lines in full operation — three Bielloni lines and one Brampton. Extrusion coating is accomplished with a Black Clawson line.

Alusa has both solventless and solvent laminators. There are three solventless laminators — Rotomec, Bielloni, and Nordmeccanica. The two solvent laminators are both Nordmeccanica. Plans are to purchase an additional solvent-based machine from Rotomec in 2004.

To complete the composite-making machinery, an old but still serviceable Kroenert wax laminator is available.

In command of the production operation is Sergoi Zanol, an engineer with 20 years of experience in the company.

Several hundred miles away in San Luis, Argentina, Alusa has built an additional production facility. There are two Rotomec rotogravure presses (eight-color) and one Bielloni flexographic press. The two extruders operating are by Brampton and Bielloni. There are also two solventless laminators (Nordmeccanica) and one solvent-based machine purchased several years ago from Otto Nielson (no longer being manufactured). As in the Santiago plant, there is a fully equipped prepress department with two Ohio engravers.

Substrate suppliers include Sigdopack and Votocel (biaxially oriented polypropylene); Terphane and Toray (polyester); Aluar and Hydro/VAW (aluminum); and Dow (polyethylene), as well as Cham Paper Group and Cartonal (paper).

Inks for both converting plants are supplied by BASF and Sun Chemical.

Unique Packaging

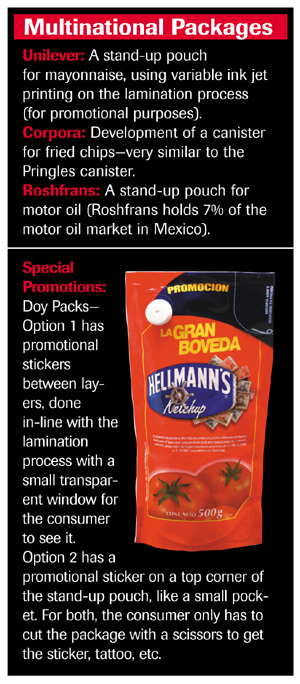

The company supplies a wide range of converted material to multinationals such as Nestlé, Danone, Procter & Gamble, Kraft, Frito-Lay, and Unilever. Domestic customers include some of the largest food processors in Chile — Corpora, Carozzi, Watt's, and Arcor.

Chile has some of the very best supermarkets in South America — magnificent stores, spotlessly clean, well lit, and fully stocked with foods from around the world. The packages presented are first class, both esthetically and technically.

A rather unique feature of condiment packaging (ketchup, mayonnaise, salad dressing, etc.) in Chile, Argentina, and Peru is that they are packaged in flexible stand-up pouches with a screw-top opening. Chilean converters prefer the screw top in the upper corner of the front panel; however, in Peru, the screw top generally is placed in the top corner seal (much more difficult to pack). The Lider chain of supermarkets in Santiago has rows and rows of flexible stand-up condiment packages converted from Alusa's material.

The same Lider store revealed the introduction of retort-pouched pet food packages. These “Whiskas” brand pouches represent the beginnings of a vibrant new market in stand-up pouches in pet food, seafood, and all other types of retort packages. Growth projections are in the 60% range in Chile, Argentina, and Brazil by 2005.

Other areas of Alusa growth include composite canisters and the introduction of pre-made retort packages. This will serve the tuna fish industry in Ecuador and Peru.

In a concluding interview with Lorenzo Zecchetto, the founder of Alusa (and a vibrant energetic executive), he said, “Alusa throughout its 40 years of history has become a world-class packaging manufacturer. We are prepared to compete in all developed markets, especially on the value-added segments.”

With a stable democracy in Chile and a nation presently led by thoughtful administrations, coupled with a free-trade agreement with the US, it's certain Alusa SA will become a world player in the flex-pack industry.

Stanley Sacharow has been in the flexible packaging industry for more than 35 years. His company, The Packaging Group, is an organizer of targeted conferences and a consultant to the international packaging/converting industry. Stan also is the author of PFFC's “Package Converting” column. Contact him at 732/636-0885; e-mail: This email address is being protected from spambots. You need JavaScript enabled to view it..

Converter Info

Alusa

Avda. Pdte. Eduardo Frei M. No. 9160

Quilicura, Santiago, Chile

+56-2-6793200; alusa.cl

Supplier Info

Rotomec (a member of the Bobst Group; bobstgroup.com

Cerutti SpA; cerutti.com

Ohio Electronic Engravers/Max Daetwyler Corp.; daetwyler.com

Uteco Converting; uteco.com

Comexi; comexi.com

Bielloni Converting; bielloni.com

Brampton Engineering; be-ca.com

Black Clawson Converting Machinery; blkclawson.com

Nordmeccanica; nordmeccanica.com

Kroenert Corp.; kroenert.com

Sigdopack; sigdopack.com

Votocel; votocel.com

Terphane; terphane.com

Toray Plastics; toraytpa.com

Aluar Aluminio; aluar.com.ar

Hydro/VAW; hydro.com

Dow Chemical; dow.com

Cham Paper Group; cham-group.com

Cartonal; cartonal.it

BASF Corp.; basf.com/printingsystems

Sun Chemical Corp.; sunchemical.com