Inspection: Lighting the Way

- Published: August 22, 2011, By By John Cusack, Quadtech Inc.

In the fast-moving consumer goods market, there can be no compromise in quality. It is not merely that a package must have high impact at the point of sale; in pharmaceuticals, tobacco, and some food markets, inability to root out defects can have fatal consequences. Imagine missing a decimal point in dosage instructions or an all-important allergy warning. Now that packages feature information in several languages, sophisticated inspection is vital to safeguard against total recalls.

A new generation of systems gives both the converter and end-user assurance of total quality. Key areas of quality control in respect to package printing are inspection (analysis of defects in the print quality), register control, and color measurement (to ensure the correct color is applied to the substrate).

Key Properties of an Inspection System

An inspection system must deliver consistent results when inspecting all packaging substrate types (paper, film, foil, and board). It must be able to inspect the entire substrate width and each and every print repeat—every time. It also must work in-line and on-the-fly at high speeds, sometimes up to 900 mpm.

Essential features include a high-resolution camera with solid-state lighting and a closed loop system in which the printed work is measured against the original PDF file or approved print sample. Furthermore, the inspection system should be fully integrated within the press and be able to communicate with slitter/rewinder equipment for fast, efficient marking and removal of defective roll material. Finally, a system must collect and store performance data and make it easily available to company staff for analysis via a central repository with intelligent analysis software linked to the IT server.

Camera Specifications

As recommended resolutions are about 200 dpi, tolerances tend to be from

The print width, minimum defect size, and print speed are the factors that determine how many cameras are needed. Generally, cameras with 4,096-pixel CCDs (charge-coupled devices) are recommended for printing applications up to about 400 mpm. This camera type covers almost all package print requirements. For instance, if a customer wants to detect a defect of 0.1 mm dia across a 1,200 mm width, the solution is to use three cameras with a combined total of 12,228 pixels.

The printing speed and camera line speed determine the minimum detectable size in the machine direction. A 4,096-pixel camera operates at 17,500 line pixels/sec. At a print speed of 300 mpm (5,000 mm/sec), the minimum machine direction resolution is calculated at 0.285 mm. As the printing process is a dynamic one, cross-substrate resolution is critical. For instance, an ink splash, spherical as it approaches the substrate, becomes a long, oval stain due to the substrate’s relative movement. In gravure, doctor blade defects are serious, potentially running for kilometers, but may be just 0.1 mm wide.

Lighting

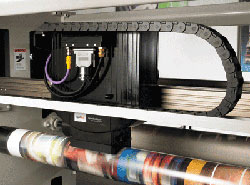

In roll-to-roll applications, the inspection equipment is located at a single position on the press, after the final printing station. Here, several cameras carry out the inspection, with solid-state lamps providing a constant illumination level on the substrate’s target inspection area. The key criteria that determine the camera and lamp types for a packaging press are:

•the mix of substrates used

•maximum printing speed

•maximum print width

•the desired resolution

The substrates matter because the transparency and reflectance of the materials have a bearing on the type and number of inspection lamps used, as well as the angles at which they are positioned. Three lamp varieties are used to illuminate the substrate:

•The top light shines a high intensity, focused beam exactly where the camera is aimed to illuminate any non-reflective and non-transparent surface.

•The foil light beams a direct reflective light at a low intensity to illuminate reflective surfaces, such as metallic foil, reflective inks, and hot foil stamp features. The beam must be reflected to the camera. Otherwise, semi-transparent inks and colors will show as a dark, grey mass.

•The back light shows defects on transparent or semi-transparent substrates, such as a clear window feature. The back light can be adjusted to provide maximum contrast against all the different colored inks printed on each job.

In all situations, white LED temperature-controlled, actively cooled lamps are recommended. These provide consistent quality levels due to their long life and detect colors across a wider spectrum than is possible with the human eye, from ultra violet (UV) to infrared. For instance, the LED lamp can identify the presence of fire retardants in cigarette filter tips.

Closed Loop System

The inspection system acts as an early warning system, whereby waste is minimized rather than eliminated. For example, a doctor blade streak is detected, and the operator is alerted where the defects are contained within the roll. The key objective is to deal with what has been detected. The database pinpoints precise locations of defects within the roll, and that information is relayed to the waste management system. The operator then will review the roll data and decide the minimum quality parameters for the job. The database will allow the operator to filter information based on defect type and size, and mark, for instance, a certain percentage for reject.

Ability to compare the printed product with a fixed golden template reference is critical to ensure consistent quality control. A “golden template” is a master image that is grabbed by the inspection system when the press is running good copy. Every printed repeat is compared to that original golden template. Other solutions use a “rolling reference” in which the first image is used to inspect the second image and so on.

However, with this approach, subtle color changes or register movement may go undetected from one repeat to the next. A fixed reference deters against quality deterioration during the print run, detecting even the slowest moving defect.

High performance software and hardware is needed to track lateral movements during the print run and make accurate comparisons between printed output and target.

PDF Verification

A PDF verification program makes structural comparisons between the golden template and the customer-approved digital artwork file. This ensures that the printed package features the right bar code, health warning, dosage, nutritional information, and price. This alerts the operator to cylinder setup errors. With enforcement of stringent health and safety regulations and packages in multiple languages and alphabets, an operator is ill-advised to check quality manually.

Continue on Page 2

Communicate & Report

A waste management system should allow control of the slitter/rewinder speed, waste removal, and roll splicing. This frees the operator from relying on error-prone, time-consuming manual detection methods. New tagless defect tracking features use weight to determine waste removal and avoid the need to contaminate a roll with tags.

Finally, no inspection would be complete without the ability to audit, store, and generate reports of both current and historical data. This enables traceability and accountability in the production process.

Color Measurement

The key requirements for effective color measurement in packaging are the following:

• a standard, objective, spectrophotometric means of color measurement

• an ability to monitor color quality throughout the print run, not just at the beginning and end of each roll

• an in-line solution that avoids the time-consuming, labor-intensive task of stopping the press and sampling off-line

• an ability to measure the color at multiple locations within a designated area, both in the machine direction and across the web

Conventional roll-to-roll applications can check color only at the end of each roll. This is a high risk scenario as it is almost impossible to tell if deviations have occurred within the run itself. The printer risks wasting thousands of meters of material.

Spectral Measurement: A Perfect Standard

Other sectors, such as commercial and magazine printing, have benefited from a common standardized method of color measurement. There is no reason why the packaging market cannot benefit as well.

Spectral data, using L*a*b* values, are reportedly the most objective means of defining color. These values are represented in three-dimensional space: a vertical luminance (L) axis, with horizontal red-green (a) and yellow-blue (b) color axes. These three values provide a reliable benchmark through the printing workflow from the package design stage.

This is a vast improvement on dealing with emotional, imprecise terms such as “fresher,” “brighter,” or “riper” that some use to denote a color. No human eye sees color in the same way; its ability to detect colors can be compromised according to environmental factors as well as tiredness. L*a*b* values remain constant and provide a roadmap to achieving consistent perfection.

Color Measurement Across the Web

Sampling color measurements at various locations anywhere across the substrate width makes it easier to detect undesired color variations that occur on just one side. Such defects can happen when uneven pressure is applied by the printing cylinder.

An in-line system can help the printer reach targets more quickly and also monitor the color throughout the job. A spectral device for packaging and narrow web applications can be integrated into an inspection system to measure spectral responses to calculate L*a*b*, ?E, Density, and ?Density values at full speeds. Such a system can deliver objectivity and take measurements fast, enabling the operator to take the necessary remedial actions that reduce makeready times and startup waste.

Inspection and color measurement are no afterthoughts. An in-line, spectrophotometric, integrated solution is the best way to deliver total customer satisfaction and minimized waste in a market where standards are extraordinarily high.

John Cusack is product manager at QuadTech Ireland in Limerick. He can be reached at +353 61 508546; This email address is being protected from spambots. You need JavaScript enabled to view it.

_____________________________________

QuadTech Ltd. | www.quadtechworld.com

Targets Achieved

Graphic Packaging Intl. (GPI), Marietta, GA, has reduced makeready waste by 50% at its Perry, GA, plant, after installing QuadTech’s Color Control System with SpectralCam. The system was installed on a 16-year-old manroland CARTOMAN web offset press.

“With margins under pressure from uncertain raw materials prices and high levels of competition, it’s essential for a printer to reduce waste to a minimum,” says GPI’s Bill Ruttan, web offset area lead.

Using the Color Control System with SpectralCam, GPI accurately reproduces unique spot colors to target aim point values. Spectral data from each patch of the color bar is evaluated to recognize and remedy deviations from color specifications, immediately issuing color adjustment requests to the ink keys. The fast response means desired color targets are achieved faster at the beginning of the print run and held consistent throughout the entire production.

Makeready is further simplified thanks to software that automatically adjusts the press’s register and color control settings when a change in repeat length is necessary. This cuts makeready time, especially as operators must frequently switch between the 26-in. and 37-in. cylinders that feature heavily on the production schedule at the Perry plant.

Graphic Packaging Intl. | www.graphicpkg.com

QuadTech Ltd. | www.quadtechworld.com

manroland | www.manroland.com