Articles

IR Industries Invests in ABB Motor Brake System for Retrofits on Coating Machines

- Published: April 30, 2004, By Nsenga Byrd Thompson, Associate Editor

With help from trusted neighbor ABB, I.R. Industries increases speed and reduces waste on its coating line

As an I.R. Industries employee since the company opened 25 years ago, Robert Stasko, VP of production, has seen the company evolve from a New York-area shipping and receiving supply company to a nationwide provider of custom printed carton-sealing and commodity tapes. With 40,000 sq ft and close to 25 employees working one ten-hour shift 5- 6 days a week, the company has grown at the same rapid pace as the polypropylene tape market, which hit the US from Europe 27 years ago.

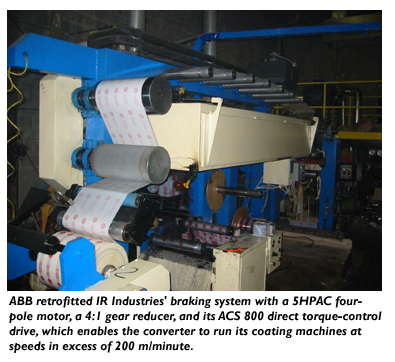

I.R. Industries maintains an econo line (for its coating operations) and a converting line (including SIAT flexo presses from Flexo Printing Inc.), as well as slitting, perforating, and laminating operations). Recently the company installed ABB’s AC motor brake system on its coating equipment in an effort to increase run speeds and reduce waste.

“We had used a air-operated brake and rewind system,” says Stasko. “We went with an ABB [because] it’s a direct motor drive that will actually increase and decrease the speed of the coater, and it works very well.”

Stasko says when working with narrow web machines, high speeds are very important. “We found out with our existing pneumatic braking system and unwind system, we couldn’t get up to speed fast enough. It was slowing us down. We were running around 160 meters per minute on our coating line. Now we’re in the excess of 200 meters per minute. Plus, what [the AC motor drive] does is get us there faster. Instead of a gradual start up to get up to speed, it’s almost instantaneous. Obviously, you don’t have as much waste. That is where the savings is—in the material,” Stasko says.

As for the company’s choice of ABB, Stasko explains convenience and familiarity played a major part in his decision. “They’re right around the corner, and they’ve done other projects for us. We’re sort of a testing facility for them,” he says. “It worked out well mainly because if we found something we thought should be improved, they were right there, and we could start working on the idea. It was an ongoing process to what we have arrived at now, so it was a learning process for both of us.”

An Equipment Facelift

Stasko says that with the high cost of purchasing new equipment, investing in a quality braking system allowed the company to maximize the efficiency of its older machines, which make up a bulk of I.R.’s converting operation.

Having older equipment, Stasko longed for more automation on the plant floor and got it with the new AC motor brake system “ our coater was showing its miles, and the price of new machines are astronomical today. So you find the need to improve what you have with today’s technology. We’ve taken machines that were 20 years old and made them almost state of the art without really having to invest in new equipment.”

“I like machines where you take all the different gauges and controls—and put it into like two buttons. Go and stop. That’s what I like a machine to do. With the ABB braking system, you just turn the unit on, and you forget about it.”

When changing adhesive formulas or material (BOPP, POLYESTER, MOPP FILMS) Stasko raves, “It took the different tension variations off of the operator and did it automatically. The machine just does it. I would say it’s 100% automation of the tension throughout the machine. We don’t have to worry about that anymore.”

Converter Info.

IR Industries

2031 Route 22

Brewster, NY, USA

800/631-4634

Supplier Information

ABB Force Measurement Div., Brewster, NY; 845/278-6810; abb.com

Flexo Printing, Oak Dale, MN 651/731-9499; flexo-siat.com