World's First 9-Manifold Extrusion Die Debuts

- Published: September 27, 2015

Just when you think you've seen everything, someone invents something ridiculously creative and novel. Nordson EDI announces the world's first nine-manifold extrusion die.

"A Nordson EDI nine-manifold flat die, the first of its kind, has been successfully commissioned, producing nine-layer film from various resins. The nine-manifold die yields very low layer thickness variation. While the degree of improvement will vary with the application, in general Nordson EDI’s nine-manifold die technology promises to reduce variation in individual layer thickness from the ±15% tolerance often encountered with comparably advanced feedblock systems to ± 5%."

This is great news for product quality and uniformity. It has long been a challenge to keep molten polymer layers separate until the last possible moment to minimize flow deformities due to rheological dissimilarities between layers, and multi-manifold dies have historically been limited to three layers, sometimes up to five layers. Multi-manifold dies eliminate the need for coextrusion feedblocks, simplifying equipment design and reducing cost.

This is great news for product quality and uniformity. It has long been a challenge to keep molten polymer layers separate until the last possible moment to minimize flow deformities due to rheological dissimilarities between layers, and multi-manifold dies have historically been limited to three layers, sometimes up to five layers. Multi-manifold dies eliminate the need for coextrusion feedblocks, simplifying equipment design and reducing cost.

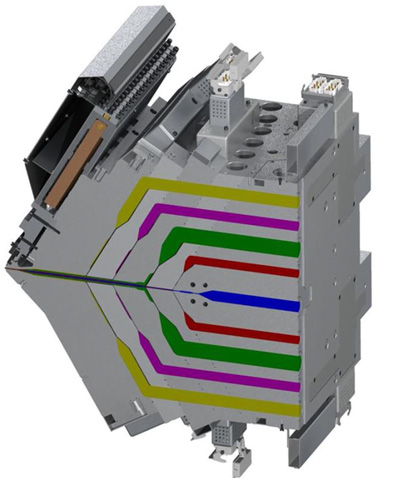

A manifold is a flow distribution channel inside the die whose complex internal geometry, engineered for a specific polymer, is designed to develop a uniform, streamlined flow and distribute the material to its full width. In a multi-manifold die, each polymer flow stream has its own manifold, and the layers are combined into a single structure only after each layer has been individually spread to its full width. See Figures 1 and 2.

By comparison, a feedblock combines multiple polymer streams into a narrow multi-layer “sandwich” that is subsequently distributed to full width in a single-manifold die. A chief reason why the multi-manifold method provides greater layer uniformity and thickness accuracy is that it avoids much of the layer-interface deformation that occurs when multiple layers pre-assembled in a feedblock are then spread simultaneously through the die.

Figure 1: Cutaway view of a nine-manifold Nordson EDI die with polymer streams represented in different colors. The streams combine to form a single multi-layer structure which exits the die at left.

Figure 1: Cutaway view of a nine-manifold Nordson EDI die with polymer streams represented in different colors. The streams combine to form a single multi-layer structure which exits the die at left.

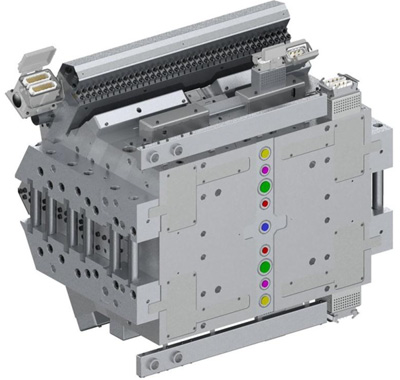

Figure 2: Rear view of a nine-manifold Nordson EDI die with entry ports for the polymer streams shown in different colors. Visible at left is one of two innovative outboard fastening structures designed to prevent leakage at either end of the die.

If you've ever disassembled even a three-manifold die, you know that having a die  cart makes the job much easier. EDI Also provides a specially designed die cart which facilitates disassembly and cleaning while helping to ensure safe and damage-free maintenance.

cart makes the job much easier. EDI Also provides a specially designed die cart which facilitates disassembly and cleaning while helping to ensure safe and damage-free maintenance.

Nordson EDI’s Ultracart™ rapid cleaning station can be designed to accommodate nine-manifold dies. Disassembled die shown here is a three-manifold unit. Look for more news on this development in the press in the coming months.

Visit www.nordson.com for more information.