SAM NA Open House

- Published: April 09, 2014, By Tom Bezigian

In a move to position itself as an alternate supplier of extrusion coating, cast film and laminating equipment to the US Market, Sung An Machinery, North America (SAM NA) held its official open house to the press and public. Andy Christie, Managing Director of SAM NA opened the day with an introduction of the company, the facilities in New York, its partners and sales presence around the world. Several key partners such as Enercon Industries, Nordson EDI, and ThermoFisher Scientific made presentations on their aspects of the pilot plant extrusion coating line.

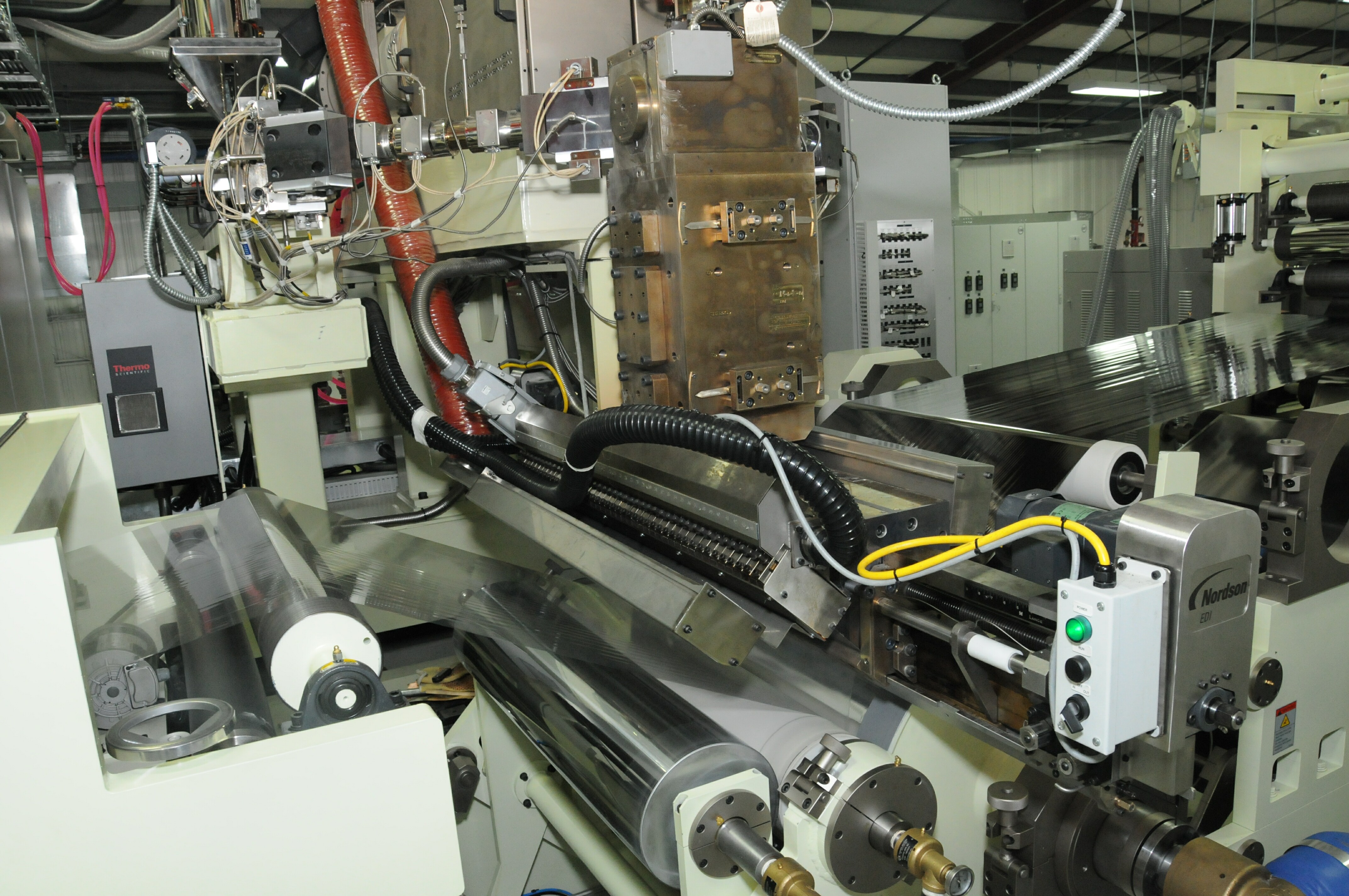

Figure 1. General overview of the pilot plant extrusion coating line

Already being a supplier of custom laminating equipment, SAM NA has an in-depth knowledge of coating, drying, laminating and web handling. The dryer system for example was designed and made by Sung An Machinery. One thing I really like about the line is that while there is a central HMI (Human-Machine Interface), there are analog and/or digital controls at each sub-station along the line, making operation easy. All to often today I see lines that operate only through the HMI, thus limiting speed and the number of things that can be done at once.

The line itself is very innovative with its use of novel design aspects unseen on one piece of equipment by this author. For example, infrared heated barrels with air cooling allow the line to run adiabatically, thus improving process stability and reducing energy consumption. The extruder drive motors are direct drive torque motors, which do not use a gearbox, thus require less space, and are energy efficient and quiet. I measured the noise level of the line without the trim blower/chopper on to be 70 dB... Very quiet indeed.

The line is equipped with Nordson EDI coextrusion and Layer Multiplier Technology, which offer converters advantages with regard to barrier properties and other nano-scale functionalities. Sam Iuliano, Chief Technologist at Nordson EDI gave a nice technical presentation on edge bead reduction die technology as well as operating and maintenance tips. He also reviewed coextrusion technology as well as the inner workings of their coex feedblock and layer multiplier. The Nordson EDI coex-layer multiplier technology in use at the SAM NA pilot facility is capable of up to 5 layers without layer multiplier technology and up to 12 layers with layer multiplier technology.

Figure 2. The extrusion laminator, bringing together primed OPET and metallized OPET with a extrusion of {LDPE with an LDPE/Nucrel blend}, showing the Nordson EDI Coextrusion Feedblock with Layer Multiplier Technology

The sample made for the open house was a OPET film laminated to a metallized OPET film. The base OPET was primed with Mica A-131X water-based PEI primer. The OPET film was provided by Celplast, and the laminating adhesive was a coextrusion of LDPE next to the primed OPET and a blend of {LDPE + EAA} next to the metallized OPET.

Figure 3. Lead Pilot Plant Technician Rob Bierman at the HMI control unit

There is an interesting relationship between Rob Beirman and I. When I owned and ran Great Lakes Technologies, LLC in Liverpool, New York, I hired Rob as an extruder helper. Now he's at the top of the heap so to speak. All in all, I have to say that the folks at SAM NA are top shelf.

Enercon Industries is another strategic partner with SAM NA. Walter Morgan and Mario Leonardelli gave presentations on corona treating in general and their equipment specifically. The unit at SAM is a 10kW 1 meter wide universal treater, capable of treating any combination of conductive or non-conductive webs.

The gauging system at SAM NA is made by ThermoFisher. Chuck Lincoln gave an in-depth talk on the topic of gauging company history and evolution, functions and capabilities of the gauge and a review of the equipment installed at SAM NA. There is fascinating new technology on the ThermoFisher gauge which should be investigated.

SAM NA is open for business. For further information on any aspect of this story, you can always write me, or contact SAM NA directly at:

Andy Christie, Managing Director, at This email address is being protected from spambots. You need JavaScript enabled to view it. or 315-934-4365 or

Ed Lincoln, VP of Sales at This email address is being protected from spambots. You need JavaScript enabled to view it. 315-934-4287

31 County Route 59, Phoenix, NY 13135 (about 20 minutes north of Syracuse).